A kind of stable indoor wall decoration material and production method thereof

A decorative material and production method technology, which is applied in the field of building materials, can solve the problems of easy dirt in flame retardant properties, complicated construction, and high price, and achieve the effects of long service life, good construction stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

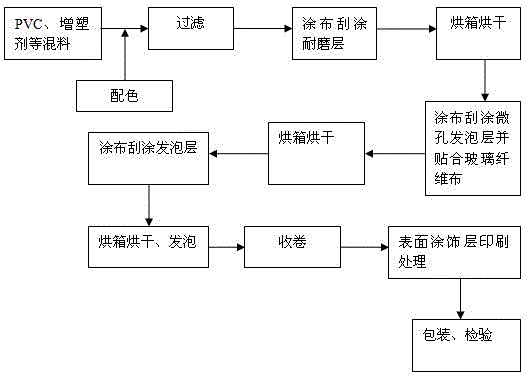

Method used

Image

Examples

Embodiment 1

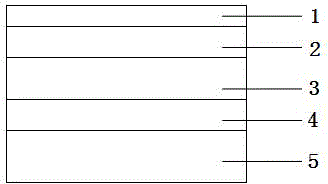

[0062] The stable indoor wall surface decoration material described in this embodiment has 5 layers, and each layer of material is:

[0063] The outermost layer is a surface finish layer treated with Bio-pruf coating.

[0064] The material composition of the surface wear-resistant layer is 42% PVC, 20% environmentally friendly plasticizer, 4% environmentally friendly stabilizer, and 34% other additives.

[0065] The material composition of the microcellular foam layer is 50% PVC, 30% environmentally friendly plasticizer, 3% environmentally friendly stabilizer, and 17% other additives.

[0066] The material composition of fiber cloth\glass fiber layer is nylon fiber.

[0067] The material composition of the foam layer is 40% PVC rubber and plastic foam material, 50% environmentally friendly plasticizer, 3% environmentally friendly stabilizer, and 7% other additives.

[0068] The PVC rubber and plastic foaming material composition is:

[0069] 65 parts of PVC powder;

[0070...

Embodiment 2

[0077] The stable indoor wall surface decoration material described in this embodiment has 5 layers, and each layer of material is:

[0078] The outermost layer is a surface finish layer treated with Bio-pruf coating.

[0079] The material composition of the surface wear-resistant layer is 25% PVC, 50% environmentally friendly plasticizer, 3% environmentally friendly stabilizer, and 22% other additives.

[0080] The material composition of the microcellular foam layer is 30% PVC, 40% environmentally friendly plasticizer, 0.5% environmentally friendly stabilizer, and 29.5% other additives.

[0081] The material composition of the fiber cloth\glass fiber layer is glass fiber.

[0082] The material composition of the foam layer is 70% PVC rubber and plastic foam material, 20% environmentally friendly plasticizer, 1% environmentally friendly stabilizer, and 9% other additives.

[0083] The PVC rubber and plastic foaming material composition is:

[0084] 90 parts of PVC powder; ...

Embodiment 3

[0091] The stable indoor wall surface decoration material described in this embodiment has 5 layers, and each layer of material is:

[0092] The outermost layer is a surface finish layer treated with Bio-pruf coating.

[0093] The material composition of the surface wear-resistant layer is 40% PVC, 29% environmentally friendly plasticizer, 2% environmentally friendly stabilizer, and 29% other additives.

[0094] The material composition of the microcellular foam layer is 60% PVC, 20% environmentally friendly plasticizer, 2% environmentally friendly stabilizer, and 18% other additives.

[0095] The material composition of the fiber cloth / glass fiber layer is hemp fiber.

[0096] The material composition of the foam layer is 22% PVC rubber and plastic foam material, 60% environmentally friendly plasticizer, 0.5% environmentally friendly stabilizer, and 17.5% other additives.

[0097] The PVC rubber and plastic foaming material composition is:

[0098] 60 parts of PVC powder; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com