Automatic testing machine and testing method for electronic detonator

An automatic testing machine and electronic detonator technology, which is used in weapon accessories, fuzes, offensive equipment, etc., can solve problems such as failure to meet production requirements, slow manual testing, and increased labor costs, ensuring quality and reducing detonator testing. Workstation personnel, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described below with reference to the accompanying drawings.

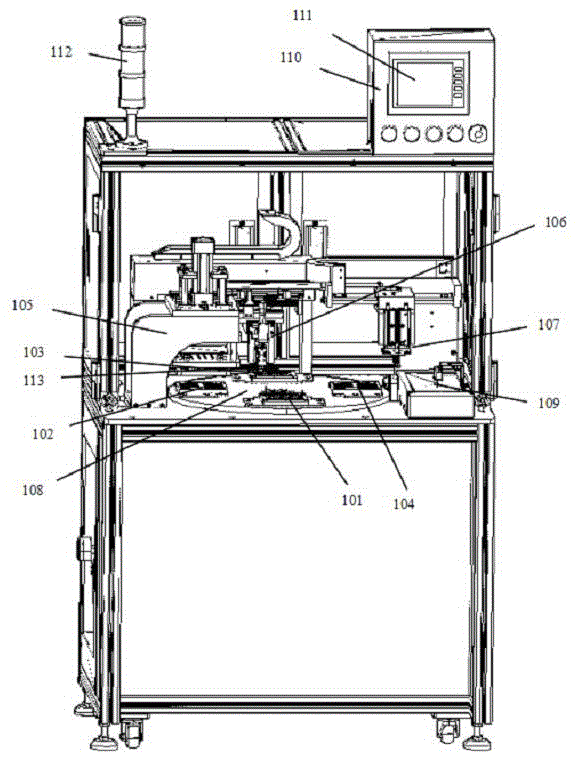

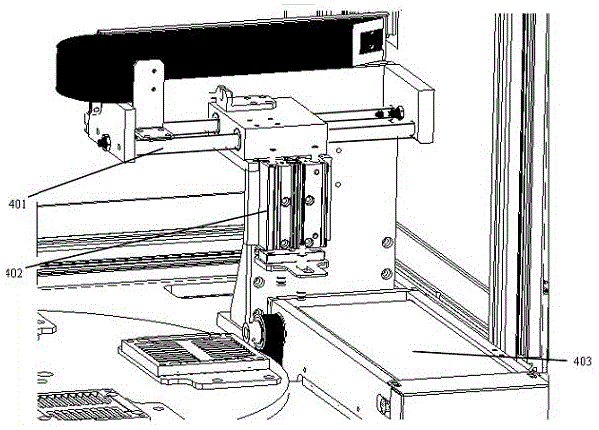

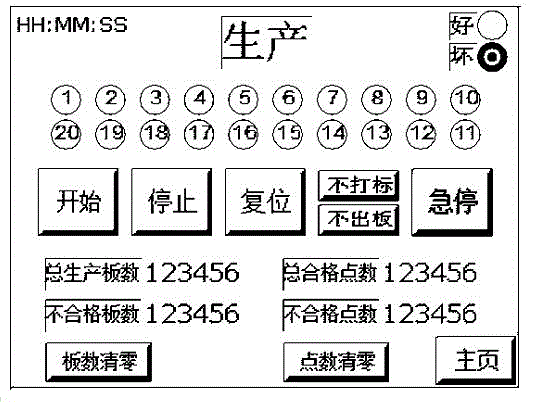

[0046] figure 1 It is the structure diagram of the electronic detonator automatic testing machine of the present invention. like figure 1 As shown, the testing machine includes station one 101, station two 102, station three 103, station four 104, testing mechanism 105, marking mechanism 106, discharging mechanism 107, turntable 108, belt transport mechanism 109, automatic The control unit 110, the touch screen 111, the indicator light 112 and the batch test fixture 113. The batch test fixture 113 includes a bottom mold and a needle plate. The bottom mold is placed on four workstations, and each bottom mold has 20 20 electronic detonators can be placed at the same time, and rotate with the station turntable. The needle plate is fixed on the test mechanism 105, and 80 probes are installed on it, which can be electrically connected with 20 electronic detonators at the same time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com