Coke reactivity and post-reaction intensity detection sample preparation apparatus and sample preparation method

A coke and coking technology, which is applied in the field of metallurgical coke physical and chemical performance testing, can solve the problems of long time-consuming, high coke hardness, complicated preparation process, etc., and achieve the effects of improving quality, consistent physical and chemical properties, and overcoming uneven particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

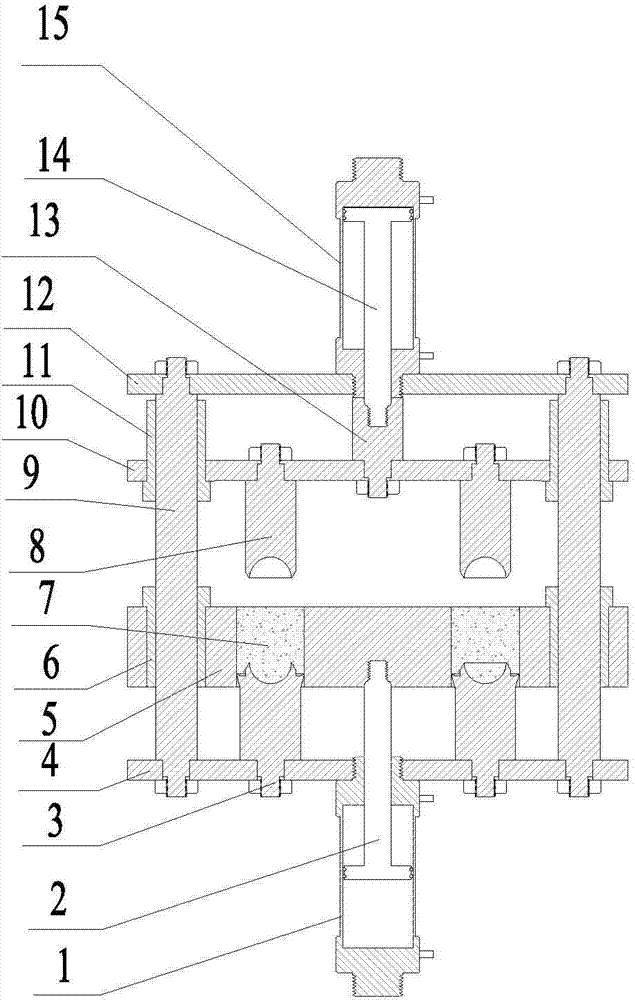

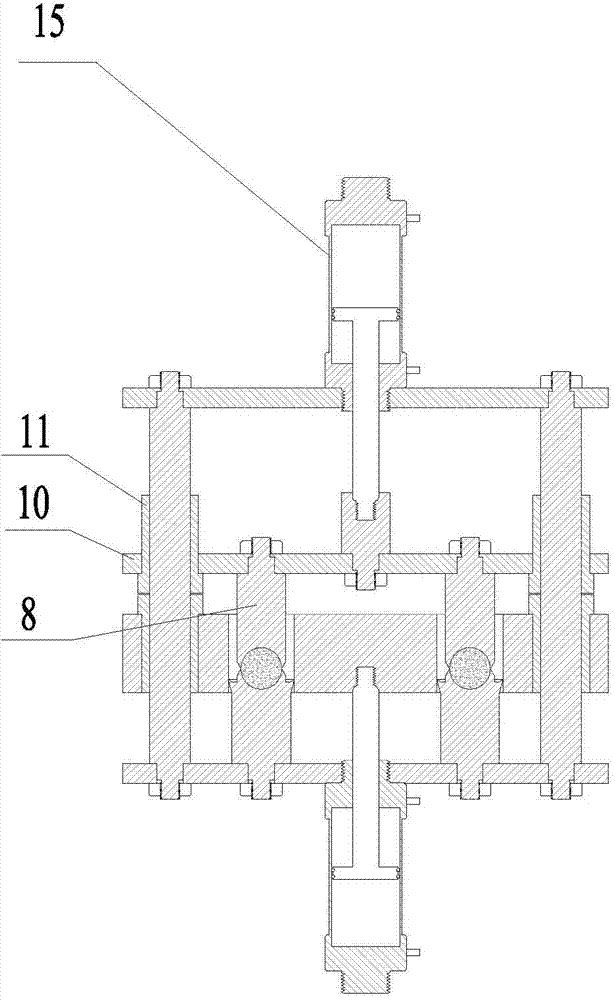

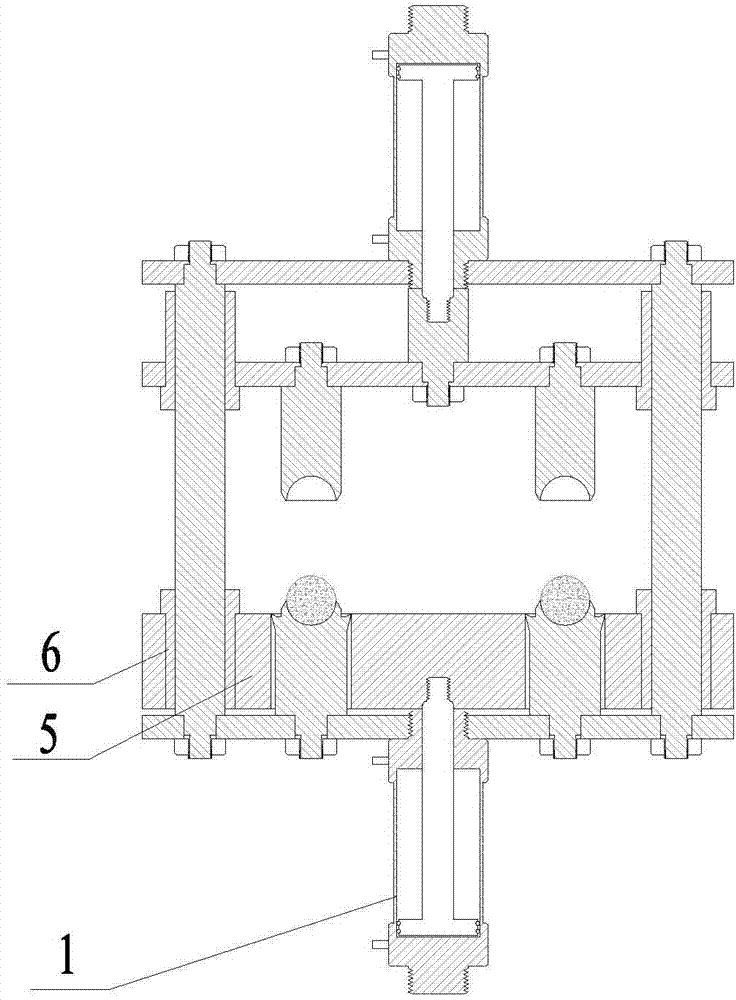

[0015] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0016] A method for preparing a coke sample is characterized in that it is carried out in the order of first pelletizing and then coking, and the specific operation steps are as follows:

[0017] 1) Put the weighed coal powder into the mold of the coke sample forming device, press the coal powder into a ball with a pressure of 20N-30N under normal temperature conditions, and get a diameter of Φ25 after demoulding. –0.1 mm, volume 8.18cm 3 , the density is 1.1g / cm 3 ~1.2g / cm 3 coal powder balls;

[0018] 2) The pulverized coal balls are placed in the coke oven of the smelting experiment. Under the condition of isolating the air and the temperature is 950 ° C ~ 1050 ° C, after 8 ~ 9 hours for high temperature dry distillation, the formed body has a diameter of Φ25 –0.1 The regular coke balls of mm are used as test samples for coke reactivity and post...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com