Process for preparing micropowdered salbutamol sulfate

A salbutamol sulfate crystallization technology, which is applied in the field of micronized salbutamol sulfate crystals, can solve the problems that there is no rotary packed bed salbutamol sulfate, it is difficult to realize industrialization, and the operation equipment is complicated, etc., and achieve micro-mixing and mass transfer process enhancement, particle size Effect of distribution narrowing and controllable nucleation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

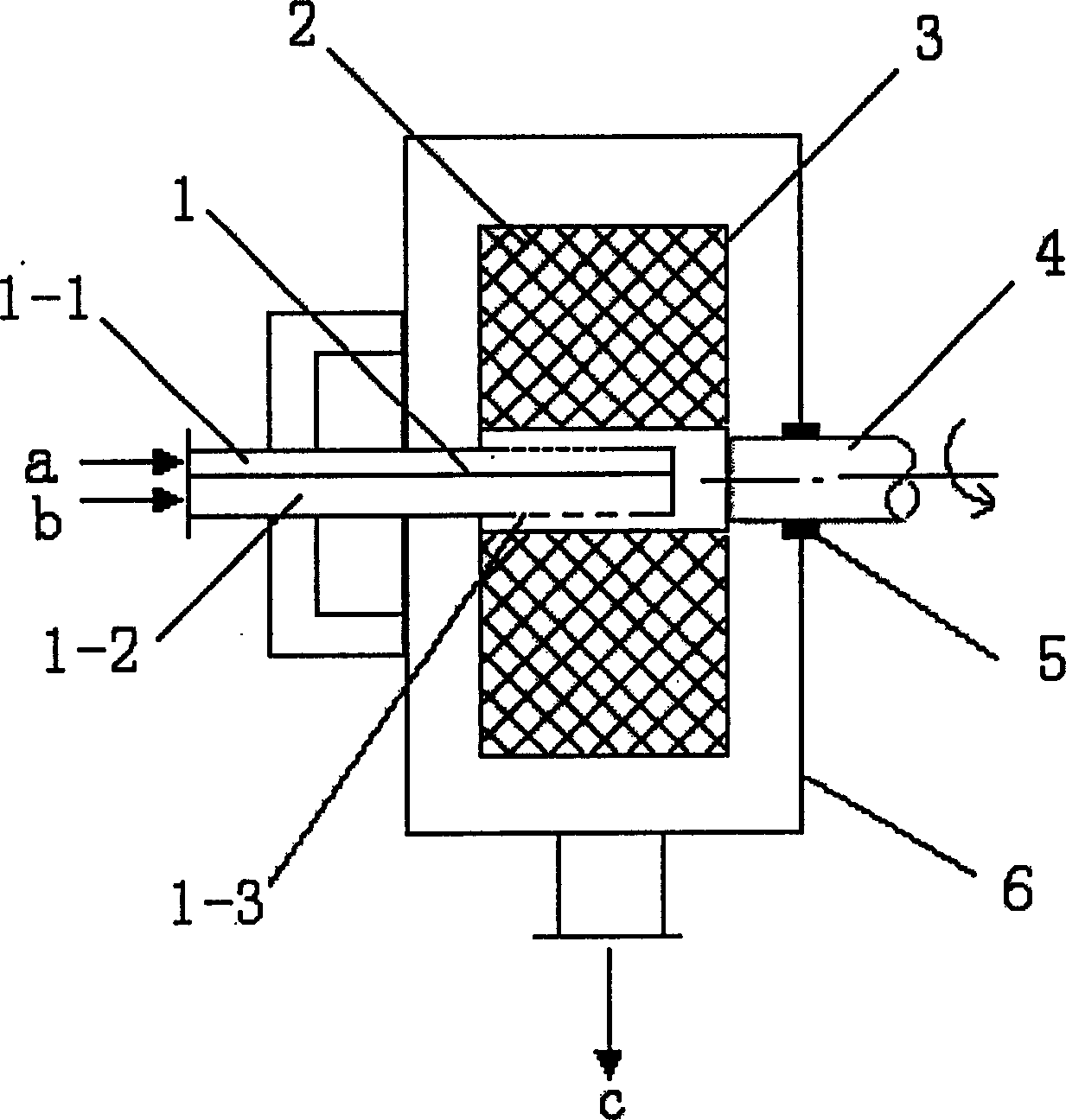

[0027] Adopt commercially available salbutamol sulfate raw material medicine, such as Figure 4 As shown in the electron microscope photo, the salbutamol sulfate raw material drug is rod-shaped particles with a short diameter of 5-20 μm and uneven particle size. Salbutamol sulfate raw material medicine is dissolved in water, is mixed with the salbutamol sulfate raw material solution A that concentration is 0.25g / ml (being about 95% of saturation concentration of salbutamol sulfate in water under this temperature condition). Adopt liquid-liquid rotary packed bed, by adjusting the frequency regulator to 30 Hz, determine that the rotation speed of the rotary packed bed is about 1800rpm, adopt a round hole liquid distributor, enter the small liquid spray hole of salbutamol sulfate crystallization raw material liquid a to be Φ0.5 ×9; the large-volume injection hole entering the anti-solvent b (acetone) is Φ1.44×9. Adopting the ratio of the flow rate of antisolvent b and salbutamol...

Embodiment 2

[0029] The operating parameters are the same as in Example 1, except that the crystallization temperature is changed to 22°C. Observation by SEM shows that the appearance of the product is similar to that of Example 1, but the average particle size of the short diameter of the crystal is about 2 μm. At least 80% of the particles have a particle size of 1.0-4.0 μm.

Embodiment 3

[0031] The operating parameters are the same as in Example 1, except that the rotation speed of the rotating bed is changed to 1140rpm. Observation by SEM shows that the appearance of the product is similar to that of Example 1, but the average particle size of the short diameter of the crystal is about 4 μm. Among them, at least 90% of the particles have a particle size of 3.0-5.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com