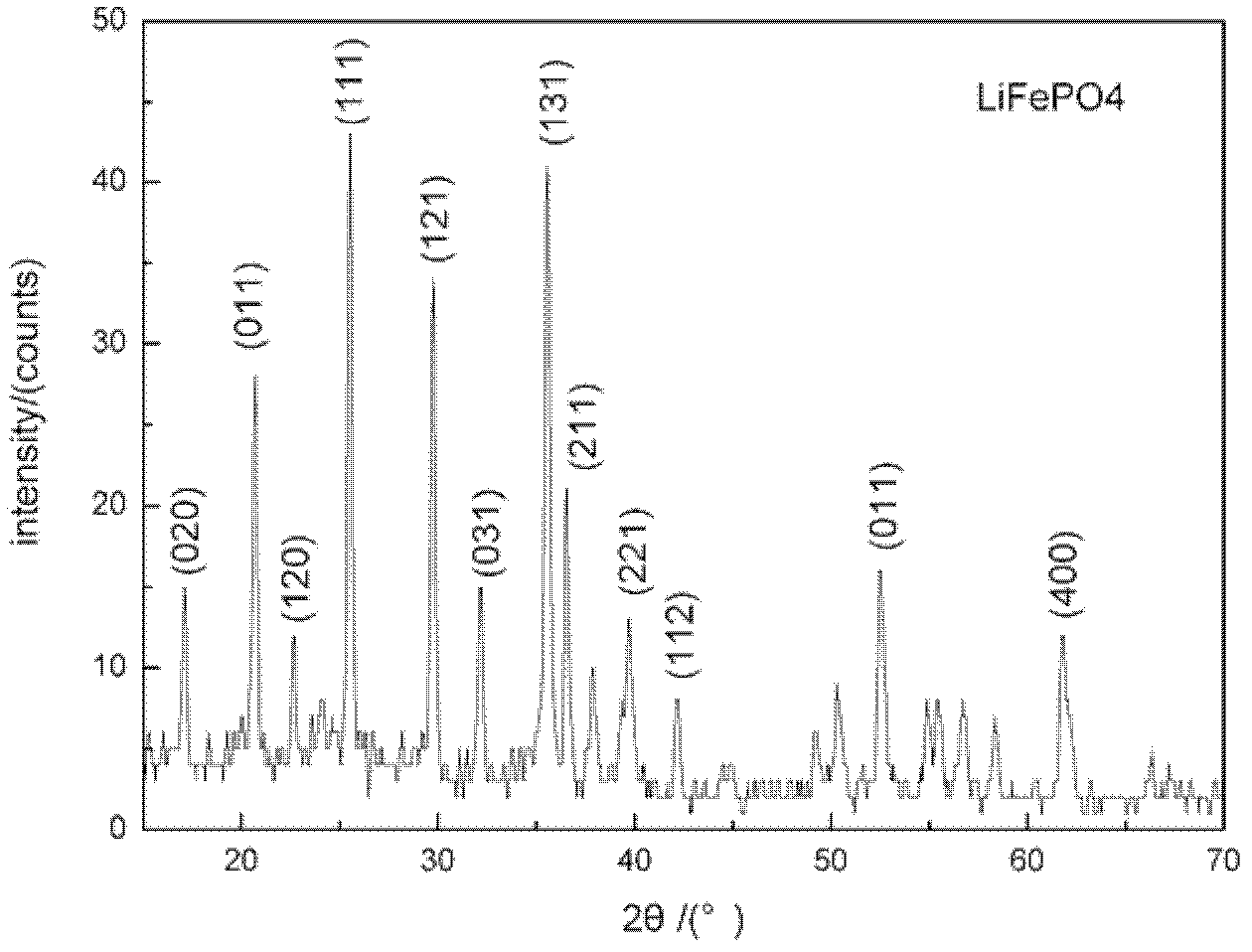

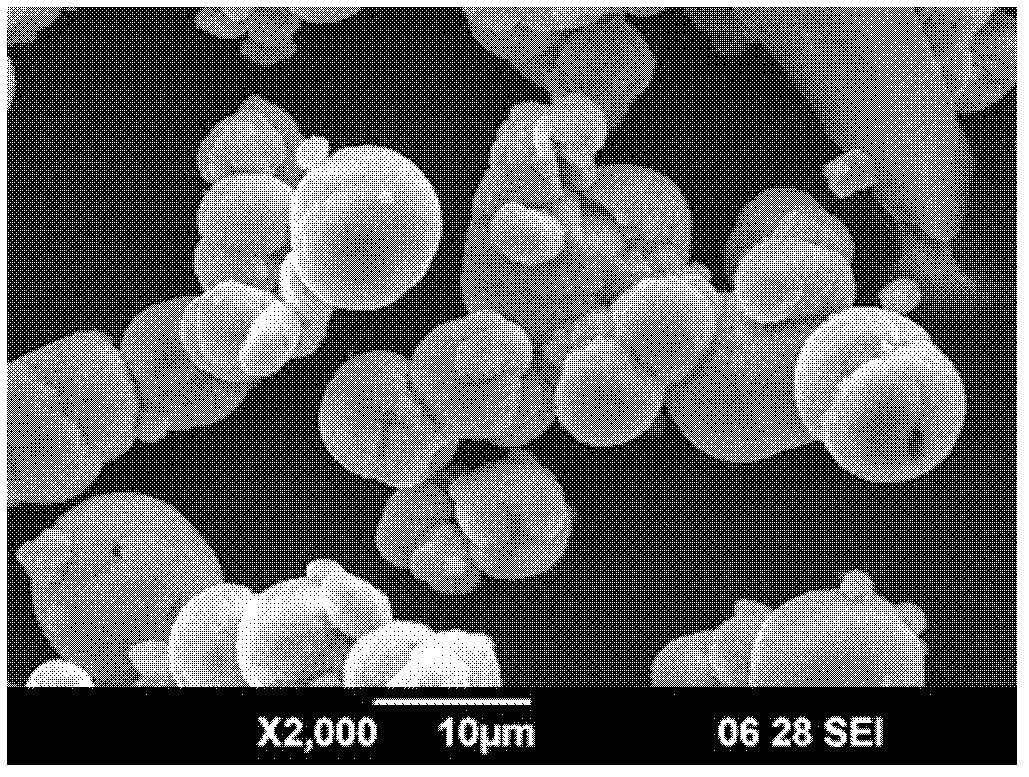

Method for preparing spheroidal LiFePO4 microlites

A microcrystalline and spherical technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low ion diffusion coefficient, poor cycle performance, low utilization rate of raw materials, etc., and achieve simple process equipment and less agglomeration , The effect of stabilizing cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) First, feed nitrogen into the distilled water to obtain distilled water A with less dissolved oxygen;

[0020] 2) The analytically pure Li 2 CO 3 , NH 4 h 2 PO 4 , FeC 2 o 4 2H 2 O according to Li:PO 4 : Fe = 3: 1: 1 molar ratio is added in distilled water A and sealed, then placed on a constant temperature heating magnetic stirrer and stirred to prepare Fe 2+ Solution B with a concentration of 0.3mol / L;

[0021] 3) Press Li 2 CO 3 and FeC 2 o 4 2H 2 The mass ratio of O mass sum and citric acid is 1: 0.8, in solution B, add analytically pure citric acid (C 6 h 8 o 7 ·H 2 O), under normal temperature magnetic stirring evenly obtains solution C;

[0022] 4) adjusting the pH value of solution C to 8.0 to obtain reaction solution D;

[0023] 5) Pour the reaction liquid D into the microwave hydrothermal reactor, control the filling ratio at 67%, seal the microwave hydrothermal reactor, put it into the microwave hydrothermal reactor with dual temperature...

Embodiment 2

[0027] 1) First, feed nitrogen into the distilled water to obtain distilled water A with less dissolved oxygen;

[0028] 2) The analytically pure Li 2 CO 3 , NH 4 h 2 PO 4 , FeC 2 o 4 2H 2 O according to Li:PO 4 : The molar ratio of Fe=0.8:1.5:0.5 is added in distilled water A and sealed, then placed on a constant temperature heating magnetic stirrer and stirred to prepare Fe 2+Solution B with a concentration of 0.05mol / L;

[0029] 3) Press Li 2 CO 3 and FeC 2 o 4 2H 2 The mass ratio of O mass sum and citric acid is 1: 0.5, in solution B, add analytically pure citric acid (C 6 h 8 o 7 ·H 2 O), under normal temperature magnetic stirring evenly obtains solution C;

[0030] 4) adjusting the pH value of solution C to 3.0 to obtain reaction solution D;

[0031] 5) Pour the reaction liquid D into the microwave hydrothermal reactor, control the filling ratio at 67%, seal the microwave hydrothermal reactor, put it into the microwave hydrothermal reactor with dual te...

Embodiment 3

[0034] 1) First, feed nitrogen into the distilled water to obtain distilled water A with less dissolved oxygen;

[0035] 2) The analytically pure Li 2 CO 3 , NH 4 h 2 PO 4 , FeC 2 o 4 2H 2 O according to Li:PO 4 : The molar ratio of Fe=5:4:3 is added in distilled water A and sealed, then placed on a constant temperature heating magnetic stirrer and stirred to prepare Fe 2+ Solution B with a concentration of 0.1mol / L;

[0036] 3) Press Li 2 CO 3 and FeC 2 o 4 2H 2 The sum of O mass and citric acid are 1: 1 mass ratios in solution B, add analytically pure citric acid (C 6 h 8 o 7 ·H 2 O), under normal temperature magnetic stirring evenly obtains solution C;

[0037] 4) adjusting the pH value of solution C to 6.0 to obtain reaction solution D;

[0038] 5) Pour the reaction liquid D into the microwave hydrothermal reactor, control the filling ratio at 67%, seal the microwave hydrothermal reactor, put it into the microwave hydrothermal reactor with dual temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com