Forming mold for asphalt test pieces of bent beam rheometer

A technology of bending beam rheometer and forming mold, which is applied in the direction of ceramic forming machine, manufacturing tool, test sample preparation, etc., can solve the problems of mold scratch, cumbersome process, increased bonding strength, etc., and achieve improved forming Efficiency, accurate test results, and improved molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described.

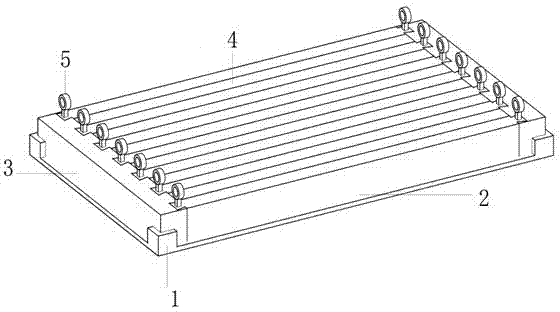

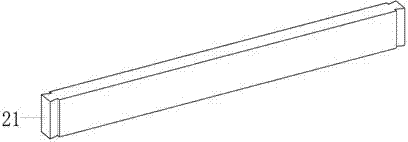

[0045] The bending beam rheometer testing asphalt specimen forming mold of the present invention comprises a base plate 1, a plurality of inner molds 2 arranged in parallel on the base plate 1, and two side molds 3 vertically arranged with the inner mold 2, and two side molds 3 Arranged in parallel and connected to one end of the inner mold 2 respectively, the semi-closed cavity formed between the bottom plate 1, two adjacent inner molds 2 and side molds 3 is the forming area of the asphalt test piece 4.

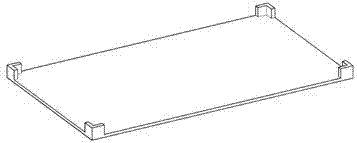

[0046] In one embodiment of the present invention, the material of the mold body is aluminum plate or stainless steel plate, and the dimensions of the asphalt sample formed by the mold body are: length 127mm±2.0mm, width 6.35mm±0.05mm, height 12.70mm±0.05mm. The four corners of the bottom plate 1 are inverted L-shaped fixing blocks, which can fix the ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com