Method for manufacturing anti-disengaging pre-forking copper core cable

A technology of anti-shedding and cable application in the direction of cable/conductor manufacturing, insulated cables, cables, etc. It can solve the problems of poor insulation performance of pre-branched cables, affect the construction and scope of application, and increase the difficulty of the process, so as to ensure electrical insulation Performance, Guaranteed electrical conductivity, and the effect of good electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

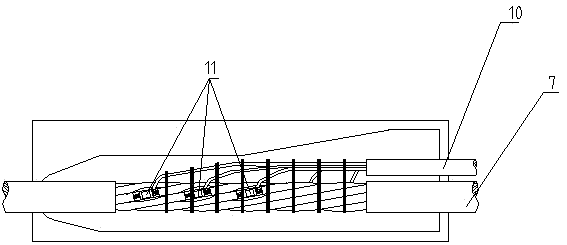

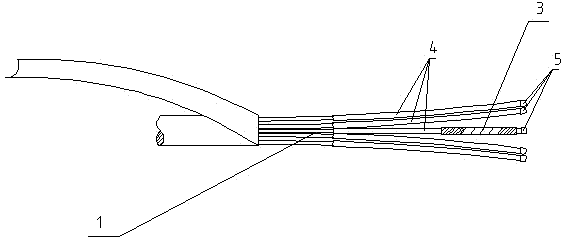

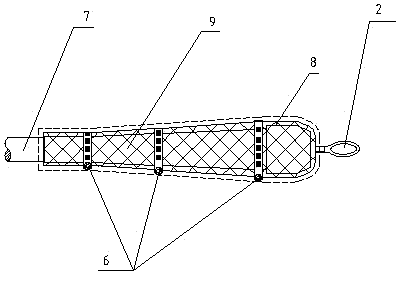

[0052] A method for preparing an anti-shedding presupported copper core cable, comprising a backbone cable, at least one pole cable, and a copper buckle, characterized in that it is prepared according to the following steps:

[0053] A) Strip the insulation and sheath of the middle part of the main cable and the end of the branch cable respectively, so that the conductor cores of each cable are exposed, and the exposed length of each cable core is equivalent, and the stripped sheath of the main cable is The leather is cut into short sections of 10cm long for later use;

[0054] B) Lay the exposed wire cores of the branch cables and the exposed wire cores of the main cable respectively, and then use a copper buckle to clamp the wire core bonding parts together, put the cable connection part into the crimping mold, start the press, Press-fit brass clasp;

[0055] C) Wrap the mica tape or insulating tape at the copper ring connector and the exposed core position first, and then ...

Embodiment 2

[0076] A method for preparing an anti-shedding presupported copper core cable, comprising a backbone cable, at least one pole cable, and a copper buckle, characterized in that it is prepared according to the following steps:

[0077] A) Strip the insulation and sheath of the middle part of the main cable and the end of the branch cable respectively, so that the conductor cores of each cable are exposed, and the exposed length of each cable core is equivalent, and the stripped sheath of the main cable is The leather is cut into short sections of 15cm long for later use;

[0078] B) Lay the exposed wire cores of the branch cables and the exposed wire cores of the main cable respectively, and then use a copper buckle to clamp the wire core bonding parts together, put the cable connection part into the crimping mold, start the press, Press-fit brass clasp;

[0079] C) Wrap the mica tape or insulating tape at the copper ring connector and the exposed core position first, and then ...

Embodiment 3

[0100] A method for preparing an anti-shedding presupported copper core cable, comprising a backbone cable, at least one pole cable, and a copper buckle, characterized in that it is prepared according to the following steps:

[0101] A) Strip the insulation and sheath of the middle part of the main cable and the end of the branch cable respectively, so that the conductor cores of each cable are exposed, and the exposed length of each cable core is equivalent, and the stripped sheath of the main cable is The leather is cut into short sections of 12.5cm long for later use;

[0102] B) Lay the exposed wire cores of the branch cables and the exposed wire cores of the main cable respectively, and then use a copper buckle to clamp the wire core bonding parts together, put the cable connection part into the crimping mold, start the press, Press-fit brass clasp;

[0103] C) Wrap the mica tape or insulating tape at the copper ring connector and the exposed core position first, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com