Radio frequency coaxial electrical connector with stamping contact element

A technology of radio frequency coaxial and contact elements, which is applied in the direction of contact parts, two-part connection devices, connections, etc., can solve the problems of low material utilization rate, high processing cost, unfavorable connector cost performance and competitiveness of car-made contact parts, etc. Achieve the effect of convenient and rapid docking and separation, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

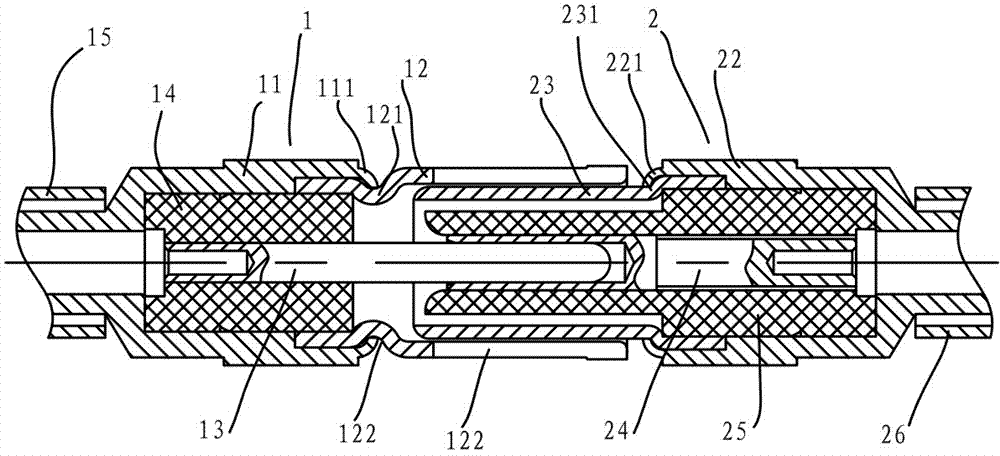

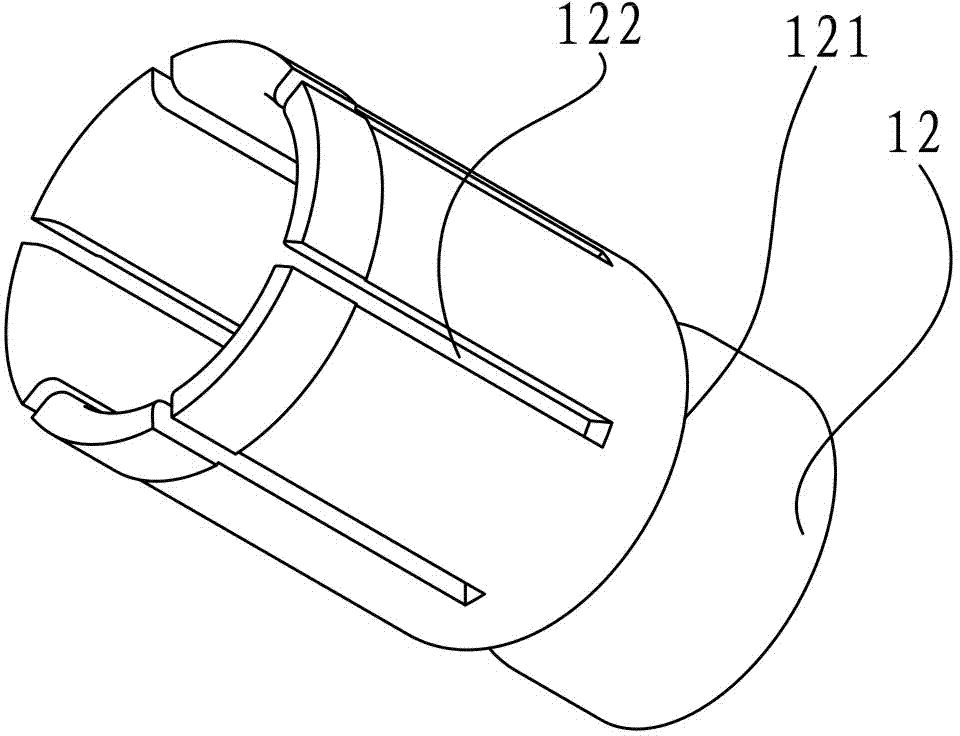

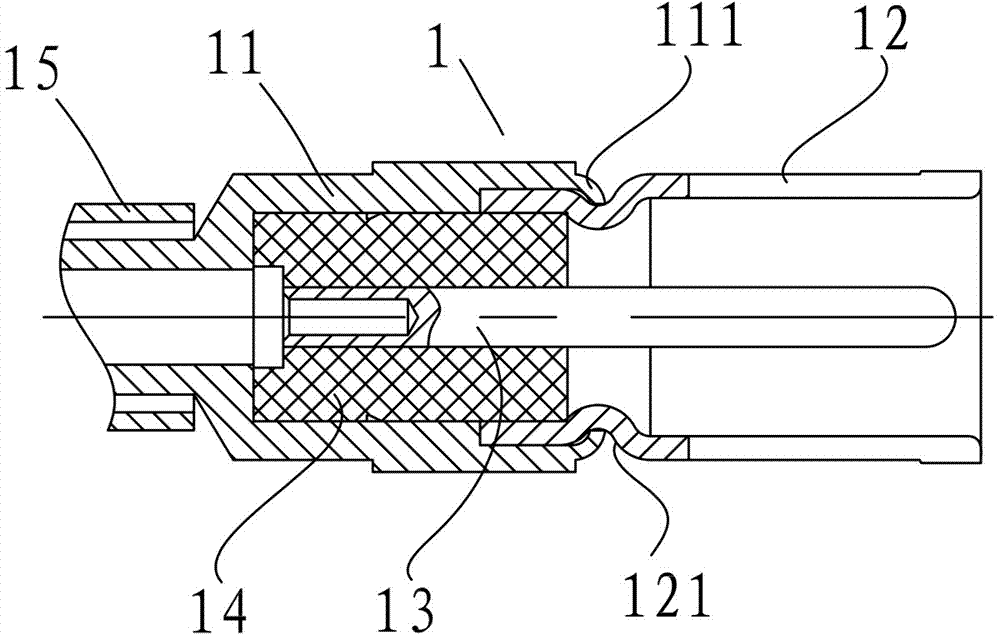

[0014] See attached figure 1 , the present invention is made up of plug 1 and socket 2, and described plug 1 is made up of plug outer conductor 11, plug inner conductor 13, plug insulator 14 and plug crimping barrel 15 and is formed; Described socket 2 is made up of socket outer conductor 22, socket The inner conductor 24, the socket insulator 25 and the socket crimping barrel 26 are set together; one end of the plug outer conductor 11 is a plug crimping interface 111 with flanging, and the plug crimping interface 111 is riveted and crimped to the plug contact 12; One end of the outer conductor 22 of the socket is a socket crimping interface 221 with flanging, and the socket crimping interface 221 is riveted and crimped to the socket contact 23; The stepped sleeve of the annular thin neck 121; the socket contact 23 is a stepped sleeve with different diameters at both ends made by stamping process; the plug 1 is docked with the socket 2, and the plug contact 12 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com