High-power optical fiber transmission system

An optical fiber transmission, high-power technology, applied in the direction of cladding fiber, optical waveguide light guide, laser components, etc., can solve the problems of refractive index, deterioration of light transmittance, easy burning at the peeling of cladding, etc., to improve reliability and reliability. Long-term stability, effectiveness in solving heat dissipation and cladding peeling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

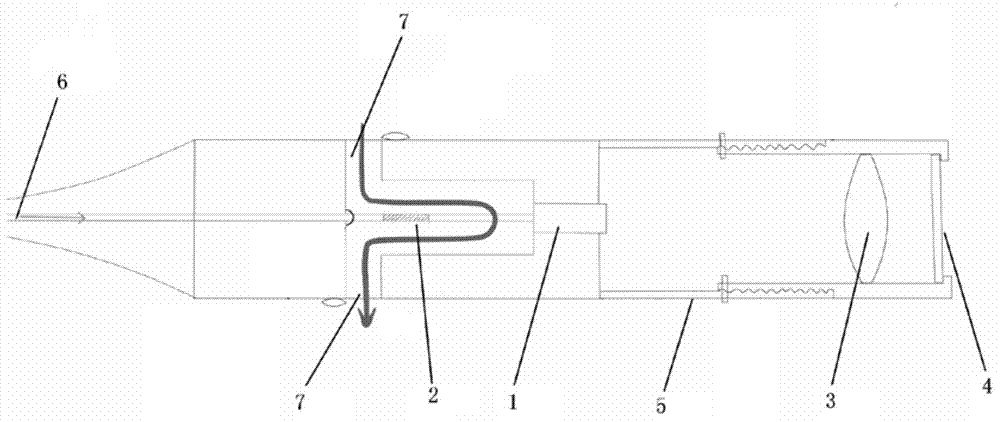

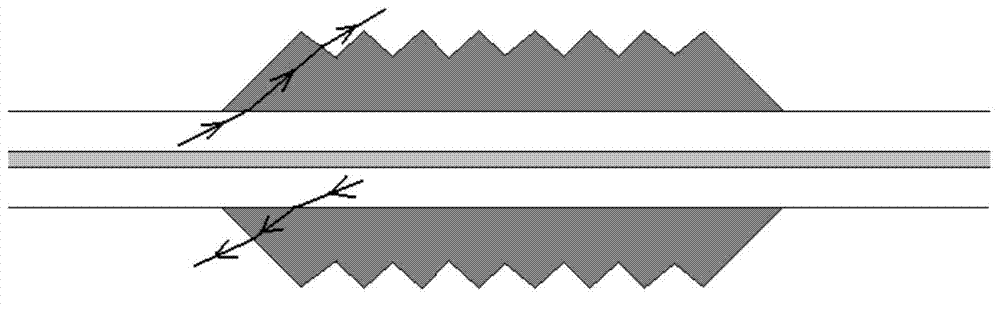

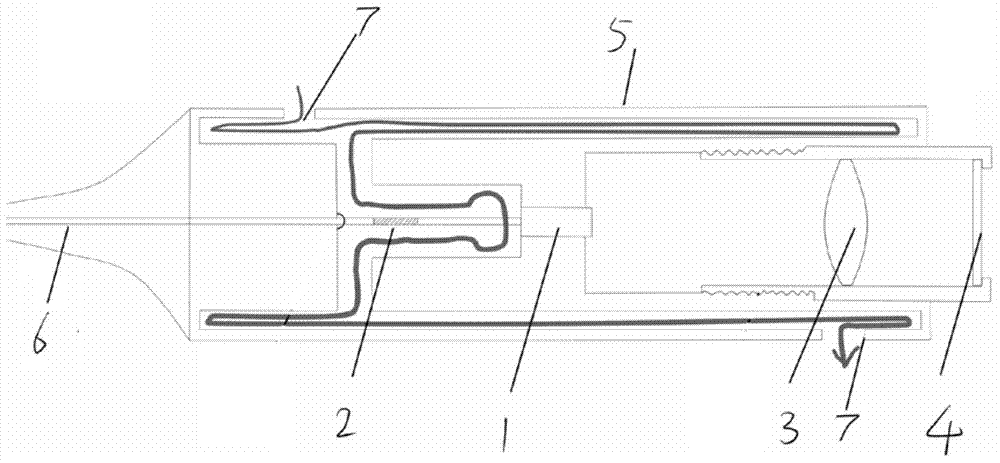

[0019] Such as figure 1 , image 3 As shown, a high-power optical fiber transmission system includes a laser transmission fiber 6, an end cap 1, a cladding stripper 2, a housing 5, a beam shaper 3, and a laser protection window 4, and is characterized in that: the laser transmission fiber 6 and One end cap 1 is welded, the cladding of the laser transmission fiber 6 is combined with a cladding stripper 2, the end cap 1, the laser transmission fiber 6, the cladding stripper 2, and the beam shaper 3 are respectively fixed in the housing 5, and the laser protection window 4 is fixed on the shell 5, and the beam shaper 3 and the laser protection window 4 are placed at the front end of the end cap 1, and the shell 5 is provided with a water cooling channel 7, and the cladding stripper 2 and a section of laser transmission fiber 6 are placed Inside the water cooling channel 7. The beam shaper 3 is an existing structure and can be purchased directly.

[0020] Taking the fiber signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com