Rapid preheating and starting circuit for fluorescent lamps

A preheating start-up, fluorescent lamp technology, applied to light sources, electric light sources, electrical components, etc., can solve problems such as increasing operating frequency, limiting application range, and power consumption, and achieves the effect of long switch life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

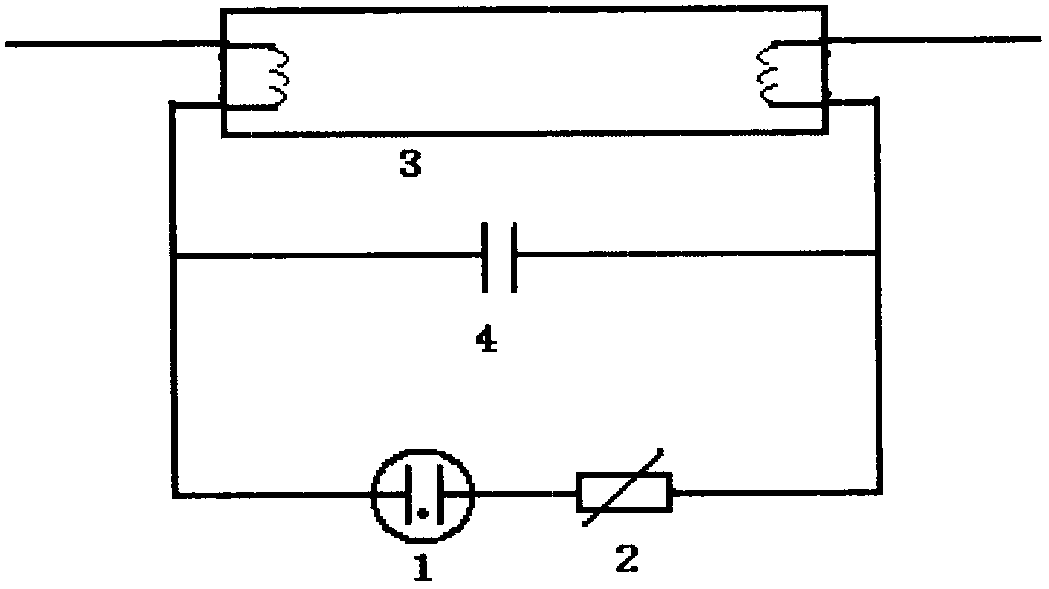

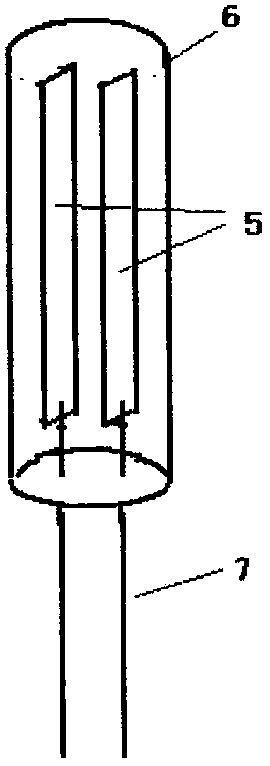

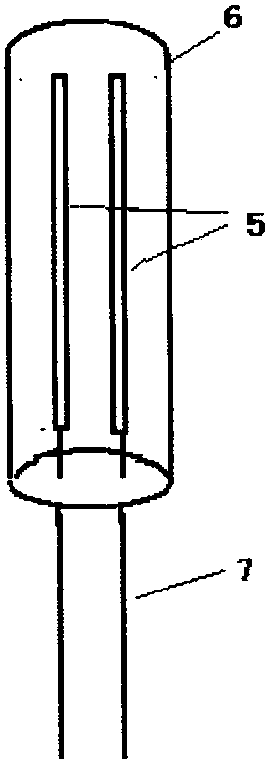

[0016] Embodiment 1 of the present invention is the fast preheating starting circuit of 5W energy-saving lamp, such as figure 1 shown. In the figure, the circuit composed of the glow discharge tube (1) and the micro PTC (2) connected in series is the rapid preheating start circuit of the present invention. It is connected to the output terminal of the electronic ballast circuit and connected in parallel with the resonant capacitor (4). Among them, the ignition voltage of the glow discharge tube is 200V to 250V, and the glow discharge maintenance voltage is 150V; the electrode of the glow discharge tube is figure 2 The sheet metal electrodes shown can also be image 3 , Figure 4 The wire-shaped metal electrode shown; the miniature PTC in it is Figure 5 The chip structure PTC shown has a thickness H of 2.0 mm, a width W of 2.0 mm, and a length L of 3.0 mm. Its Curie temperature is 75° C. and its room temperature resistance is 4000 ohms.

[0017] Embodiment 2 of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com