Positive electrode material for lithium secondary battery, and method for producing said positive electrode material

A lithium secondary battery and cathode material technology, applied in secondary batteries, battery electrodes, batteries, etc., can solve the problem of low electronic conductivity and achieve the effect of inhibiting structural deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0131] "1. Synthesis process"

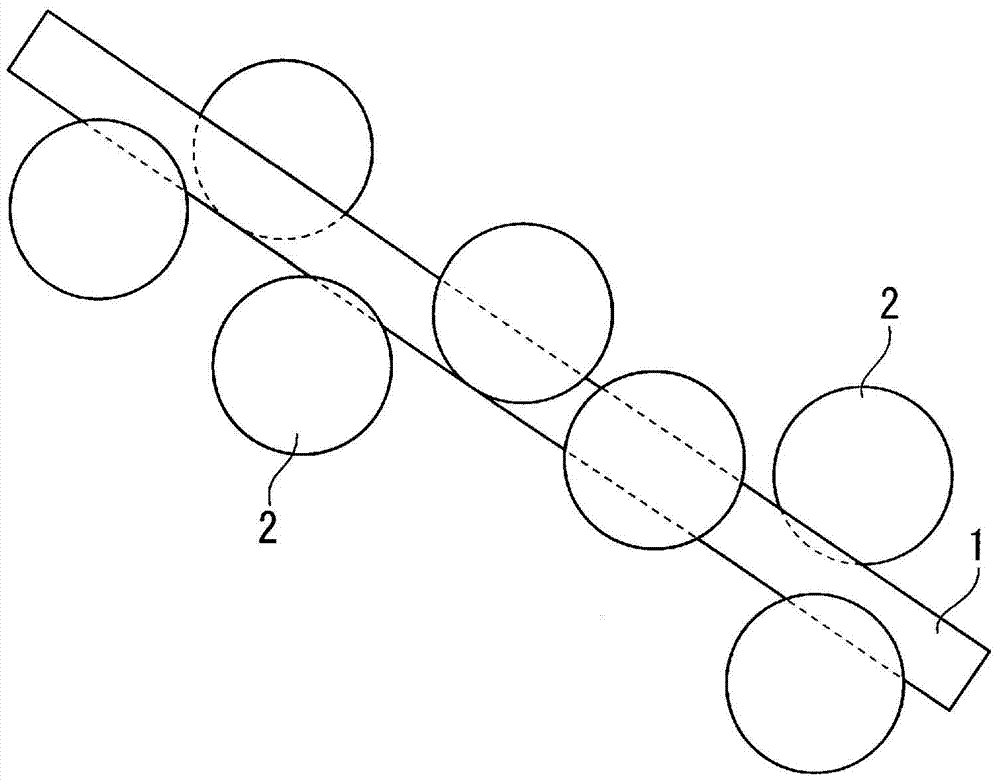

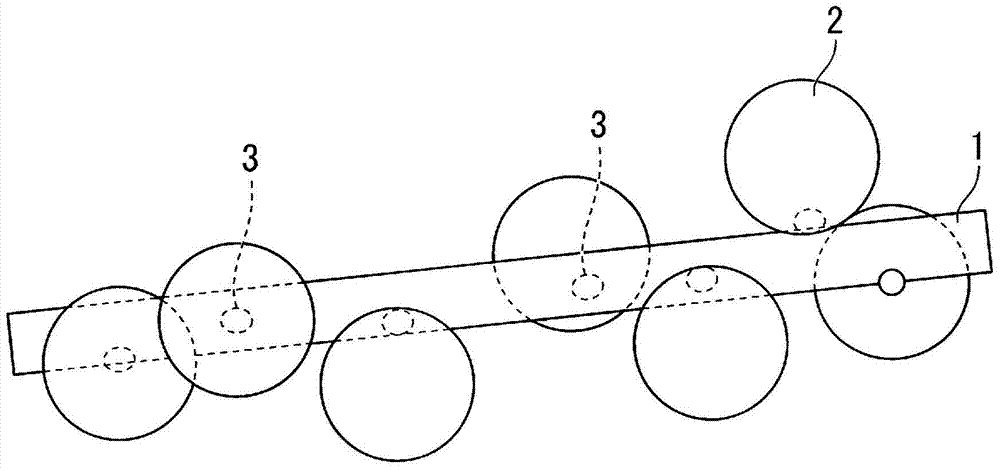

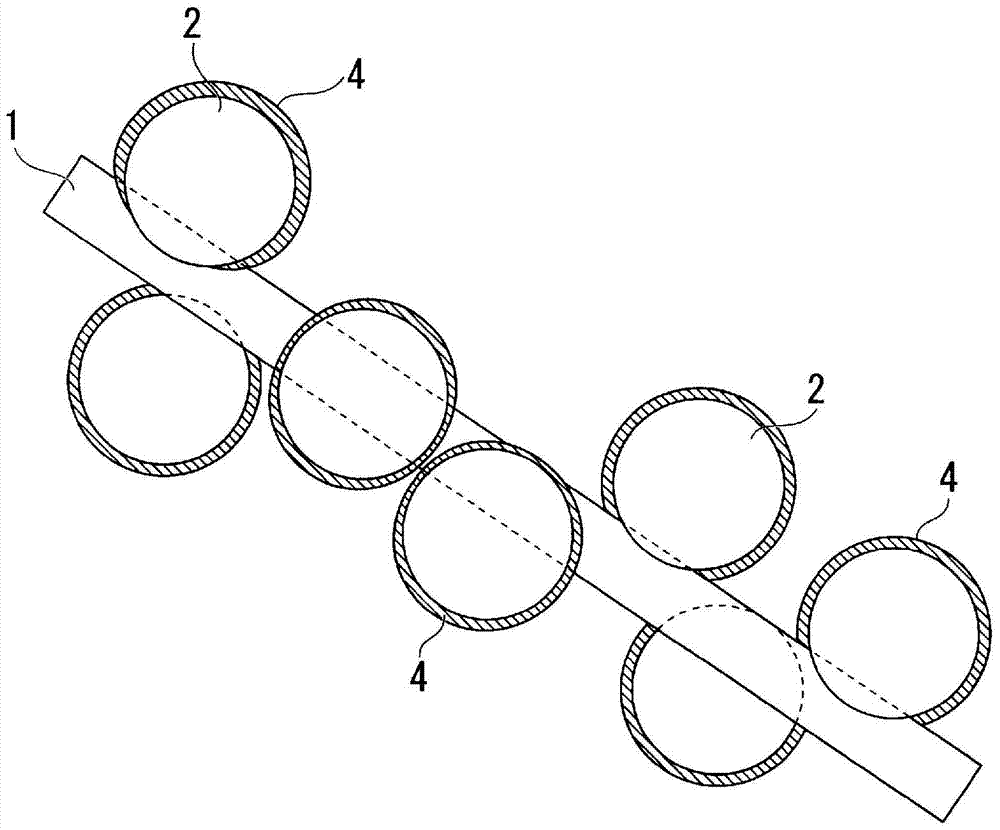

[0132] Dissolve 123g of LiOH·H 2 After O, 3.1 g of carbon fiber (Showa Denko Co., Ltd. VGCF-H (VGCF is a registered trademark. The same applies hereinafter)) was added and stirred. The carbon fibers had an average fiber length of 15 μm, a fiber diameter of 150 nm, and an aspect ratio of 100. Furthermore, stirring was carried out slowly adding 113 g of phosphoric acid of concentration 85%. In this way, the first raw material liquid was prepared.

[0133] Next, in a glove box, after dissolving 1.82 g of ascorbic acid in 700 mL of water, 272 g of FeSO 4 ·7H 2 O, the second raw material liquid was prepared.

[0134] Next, the first and second raw material liquids were mixed and stirred in a glove box, and then placed in an autoclave and sealed. Then, after the autoclave was heated up from room temperature to 120° C. over 1 hour, it was kept at 120° C. for 3 hours, and after being heated up to 200° C. over 1 hour, it was kept at 200° C. for 3 h...

Embodiment 2)

[0147] Instead of the carbon fiber of Example 1, a carbon fiber (VGCF-H manufactured by Showa Denko Co., Ltd.) was produced using Fe as a catalyst with a residual rate of Fe of 0.1%, and the first raw material liquid was prepared using it, except that it was the same as that of Example 1. The positive electrode material of Example 2 and the coin-type battery of Example 2 were successfully produced. The content of carbon fibers in the positive electrode material of Example 2 was 2% by mass, the content of coated carbon was 2% by mass, LiFePO 4 The particle content was 96% by mass.

[0148] And under the same conditions as in Example 1, a charge-discharge cycle test was carried out. As a result, the discharge capacity for the 2nd time was 151mAh / g, and the discharge capacity for the 500th time was 140mAh / g. The discharge capacity maintenance rate was 92.7%.

[0149] In addition, a temperature cycle test was carried out under the same conditions as in Example 1. As a result, th...

Embodiment 3)

[0151] Dissolve 113g of Li in 700mL of water in a glove box with a nitrogen atmosphere controlled to an oxygen concentration of 0.5% or less 3 PO 4 After that, 3.1 g of the same carbon fiber (VGCF-H manufactured by Showa Denko Co., Ltd.) as in Example 1 was added and stirred to prepare a first raw material solution, and the positive electrode of Example 3 was produced in the same manner as in Example 1. Materials and the coin-type battery of Example 3. The carbon fiber content in the positive electrode material of Example 3 was 2% by mass, LiFePO 4 The particle content was 96% by mass.

[0152] And under the same conditions as in Example 1, the charge-discharge cycle test was carried out. As a result, the discharge capacity for the 2nd time was 153mAh / g, and the discharge capacity for the 500th time was 141mAh / g. The discharge capacity maintenance rate was 92.2%.

[0153] In addition, a temperature cycle test was carried out under the same conditions as in Example 1. As a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com