Method of dividing batches of re-baked tobacco leaves according to weight

A technology of re-curing tobacco leaves and weight, applied in tobacco, tobacco preparation, application, etc., can solve problems such as process quality, unfavorable process analysis, difficult process quality control, and imperfect monitoring system, so as to eliminate abnormal conditions of production quality and strengthen Effect of process quality control and improvement of overall quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

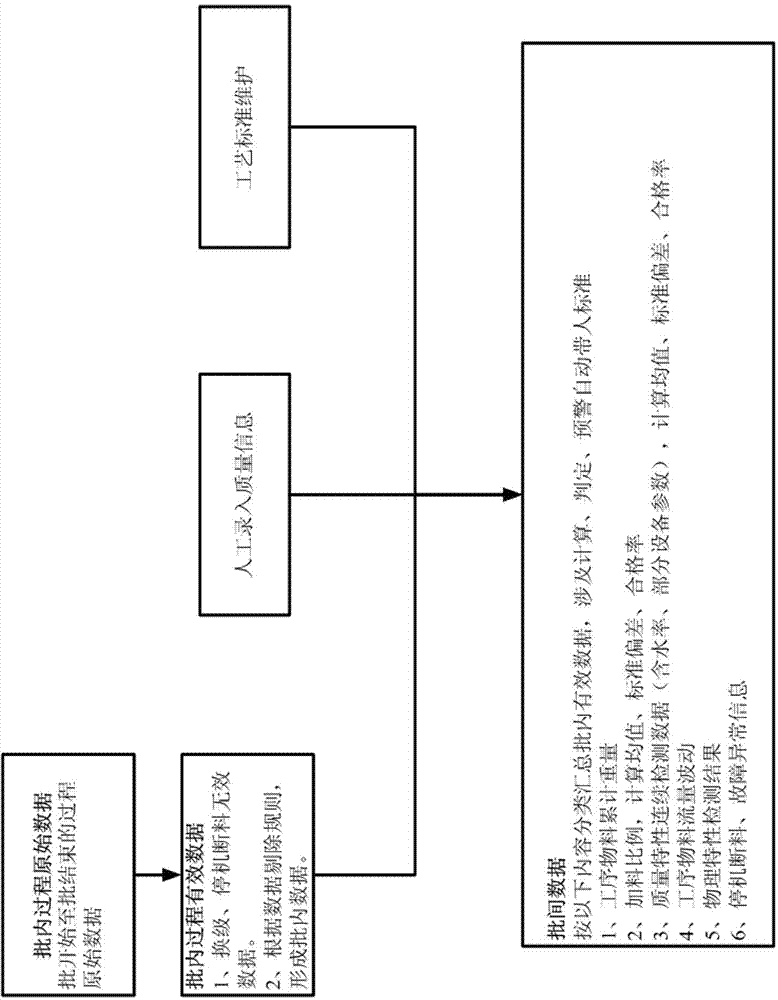

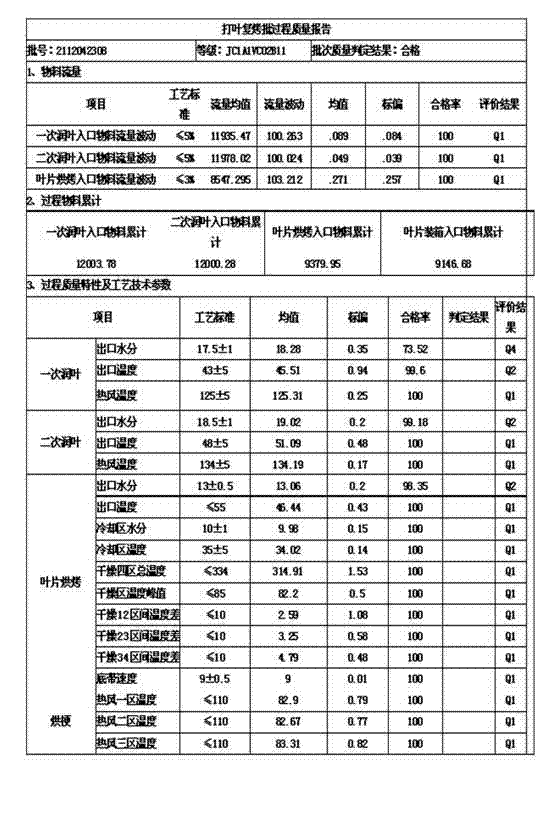

[0018] The data collection system of the present invention firstly collects "intra-batch process raw data" from the beginning of the batch to the end of the batch, and forms "intra-batch process effective data" according to the data elimination rules. The batch quality evaluation index is calculated on the basis of the original data and valid data, and the batch quality report and the inter-batch data analysis report are formed according to the batch definition rules, combined with the offline detection data and process abnormal information. The specific steps are as follows:

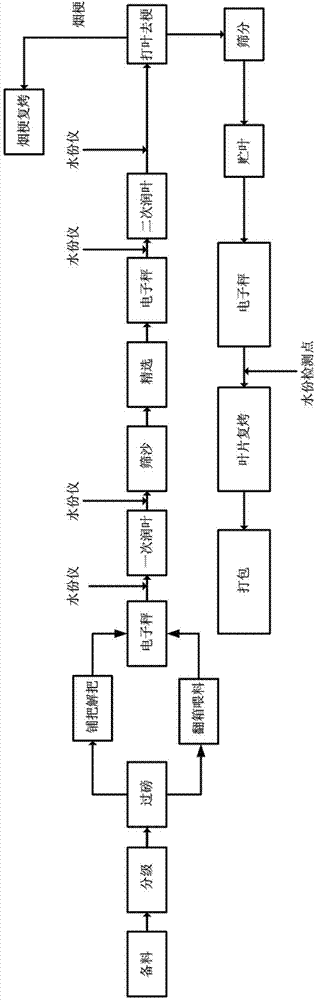

[0019] The re-roasting production line is divided into first moistening, second moistening and leaf beating, leaf redrying, and packaging processes. Quality management personnel conduct sampling tests at places equipped with moisture meters and moisture monitoring points, and enter the test results into the data acquisition system. According to the rated production capacity of the production line for one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com