Machining method for high-precision straight outline ring surface worm gear pair

A processing method and high-precision technology, applied in the direction of worms, worm wheels, and components with teeth, etc., can solve the problems of difficult control of the blade clearance, hindering the worm from entering the correct position, and inconvenient processing and installation, so as to facilitate industrialization. Significant strategic significance, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

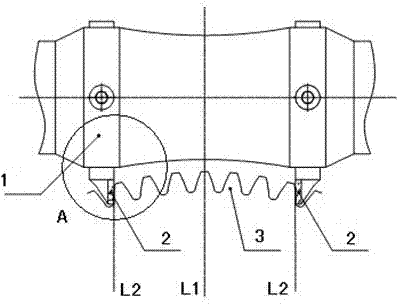

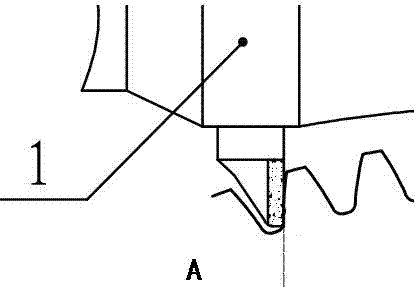

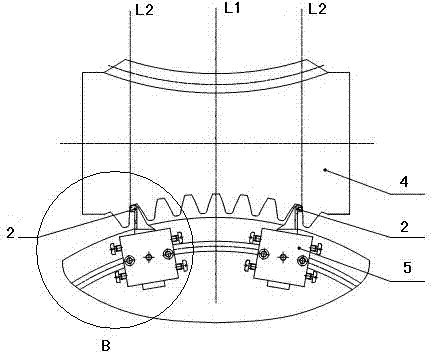

[0035] figure 1 It is a schematic diagram of the worm gear processing method. The worm gear machine is used for processing. First, the flying knife process is used for rough machining, and then the finish machining is performed after the gear cutting is completed. During finishing machining, two straight-edged cutters 2 (long blades) with the same tooth shape are installed on the tool bar 1 of the worm gear master machine. The blades are inlaid with carbide blades, and the straight-profile toroidal worm gear 3 to be processed is installed on the workbench. superior.

[0036] When machining the straight-profile toroidal worm gear 3, its end face and outer circle are calibrated, and then accurately installed on the workbench of the worm gear master machine, and then the tool bar 1 is installed on the tool holder of the worm gear master machine, and the straight-edged cutter 2 is adjusted according to the required distance Put the size into the holes at both ends of the tool bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com