A diamond roller grinding wheel dresser device

A diamond roller and grinding wheel dresser technology, which is applied in the direction of abrasive surface adjustment devices, metal processing equipment, grinding machine parts, etc., can solve problems such as long dressing time and difficult complex profiles, and improve production efficiency and production Efficiency and product quality, the effect of quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

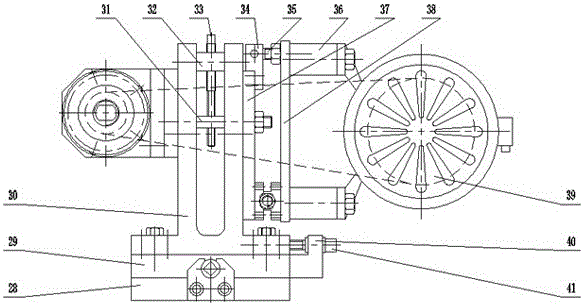

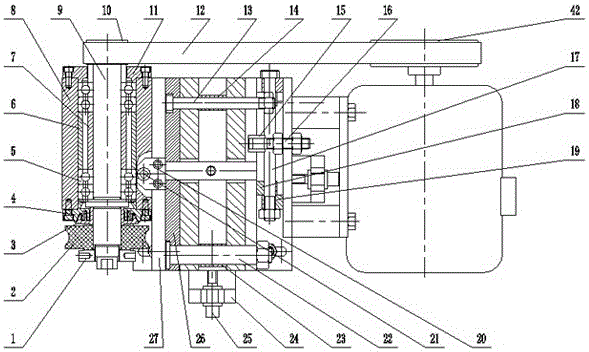

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 and figure 2 As shown, a diamond wheel dressing device of the present invention includes a round nut 1; a diamond wheel 2; a sealing cover 3; a front end cover 4; a bearing 5; an inner spacer 6; an outer spacer 7; 9; small pulley 10; rear end cover 11; multi-wedge belt 12; fixed screw 13; spacer A14; adjusting seat A15; adjusting screw A16; hinge screw 17; fixed hinge 18; B21; Shaft pin 22; Spacer B23; Adjusting seat C24; Adjusting screw C25; Horizontal adjustment base plate 26; Vertical adjustment base plate 27; Axial adjustment base plate 28; Radial adjustment base plate 29; Shaft 32; Adjusting screw 33; Adjusting seat D34; Adjusting screw rod 35; Shock absorber 36; Adjusting base plate 37; Motor base plate 38; Motor 39; Adjusting seat E40;

[0018] During work, the diamond roller dresser is driven by the motor 39 to rotate the large pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com