AAO (Anaerobic-Anoxic-Oxic)-biological contact oxidation strengthened denitrification and dephosphorization device and real-time control method of low C/N sewage treatment

A biological contact, nitrogen and phosphorus removal technology, applied in the field of sewage biological treatment, can solve the problems of low denitrification and phosphorus removal efficiency, difficulty in achieving nitrogen and phosphorus removal effects, and low nitrification efficiency, and achieve enhanced denitrification and phosphorus removal effects, The effect of solving the contradiction between long and short mud ages and alleviating the shortage of carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

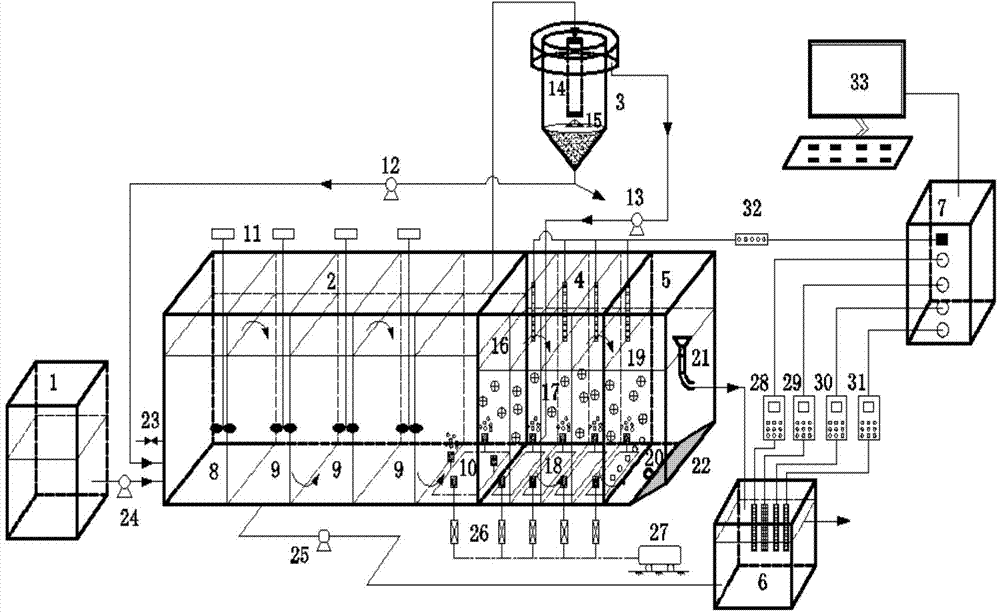

[0036] The DO sensor 32 collects the dissolved oxygen concentration in each compartment of the biological contact oxidation tank 4 online, and the control of the nitrification process can be realized through the calculation output of the computer 33 . The DO in the first two grids is controlled at 2.5-4.0mg / L, the DO in the last two grids is controlled at 0.5-2.0mg / L, and the total gas volume is 0.1-0.6m 3 / h. NH 4 + The sensor 28 collects the ammonia nitrogen concentration in the outlet water tank 6 online, and obtains the real-time control variable through the calculation output of the computer 33 . When NH 4 + When the concentration is ≥2mg / L, increase the aeration rate to 0.5-0.6m 3 / h; when NH 4 + When the concentration is ≤0.5mg / L, reduce the aeration rate to 0.3~0.4m 3 / h; when NH 4 + Concentration ≤ 0.5mg / L and effluent nitrite accumulation rate NO 2 - / NO x - ≤30%, reduce the aeration rate to 0.1~0.2m 3 / h.

specific Embodiment approach 2

[0037] The DO sensor 32 collects the dissolved oxygen concentration in each compartment of the biological contact oxidation tank 4 online, and the control of the nitrification process can be realized through the calculation output of the computer 33 . The DO in the first two grids is controlled at 2.5-4.0mg / L, the DO in the last two grids is controlled at 0.5-2.0mg / L, and the total gas volume is 0.1-0.6m 3 / h. NO 3 - Sensor 29 and NO 2 - The sensor 30 collects the concentrations of nitrate nitrogen and nitrite nitrogen in the outlet water tank 6 online, and obtains real-time control variables through the calculation output of the computer 33 . when NO 3 - +NO 2 - When the concentration is ≥14mg / L, increase the reflux ratio of the nitrification solution to 300% to 400%; when NO 3 - +NO 2 - When the concentration is ≤6mg / L, reduce the reflux ratio of the nitrification solution to 100%-200%.

specific Embodiment approach 3

[0038] The DO sensor 32 collects the dissolved oxygen concentration in each compartment of the biological contact oxidation tank 4 online, and the control of the nitrification process can be realized through the calculation output of the computer 33 . The DO in the first two grids is controlled at 2.5-4.0mg / L, the DO in the last two grids is controlled at 0.5-2.0mg / L, and the total gas volume is 0.1-0.6m 3 / h. The TP sensor 31 collects the TP concentration in the outlet water tank 6 online, and obtains the real-time control variable through the calculation output of the computer 33 . When the TP concentration is ≥1mg / L, increase the reflux ratio of the nitrification solution to 300%-400%; when the TP concentration is ≤0.2mg / L, reduce the reflux ratio of the nitrification solution to 100%-200%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com