Antifreeze fluid by taking composite corrosion inhibitor as main raw material

A compound corrosion inhibitor and main raw material technology, applied in the field of antifreeze, can solve the problems of metal surface corrosion and high production cost of antifreeze, achieve good anti-corrosion effect, non-toxic corrosion inhibition effect, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

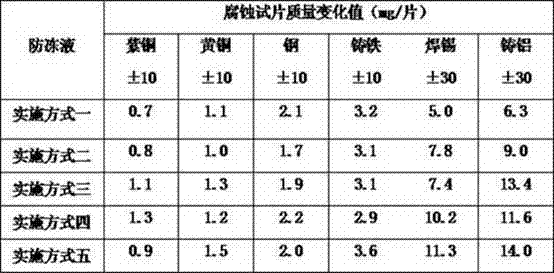

Examples

specific Embodiment approach 1

[0007] Specific Embodiment 1: The freezing point of the antifreeze that uses composite corrosion inhibitor as the main raw material in this embodiment is -50°C, and the antifreeze is composed of 600kg ethylene glycol, 630kg water, 16.46kg composite corrosion inhibitor and 0.1kg fluorescein Composition; Described composite corrosion inhibitor is made up of 12.5kg borax, 3kg sodium benzoate, 0.6kg benzotriazole, 0.26kg caustic soda, 0.1kg methyl silicone oil; Described ethylene glycol adopts content to be 98% industrial grade ethylene glycol.

[0008] The preparation method of the antifreeze is as follows: add ethylene glycol into the reaction kettle, then inject water, then add borax, sodium benzoate, benzotriazole, caustic soda, methyl silicone oil and dye in turn, and stir repeatedly until completely dissolved Afterwards, stand still for 4 hours, and discharge promptly obtain the antifreeze finished product of the present embodiment.

specific Embodiment approach 2

[0009] Specific implementation mode two: the freezing point of the antifreeze liquid with composite corrosion inhibitor as the main raw material in this embodiment is -45°C, and the antifreeze liquid is composed of 550kg ethylene glycol, 570kg water, 15.59kg composite corrosion inhibitor and 0.09kg fluorescein Composition; Described composite corrosion inhibitor is made up of 11.9kg borax, 2.8kg sodium benzoate, 0.55kg benzotriazole, 0.25kg caustic soda, 0.09kg methyl silicone oil; Described ethylene glycol employing content is 98% Industrial grade ethylene glycol. The preparation method of the antifreeze in this embodiment is the same as that in Embodiment 1.

specific Embodiment approach 3

[0010] Specific implementation mode three: the freezing point of the antifreeze solution with composite corrosion inhibitor as the main raw material in this embodiment is -40°C, and the antifreeze solution is composed of 470kg ethylene glycol, 500kg water, 14.61kg composite corrosion inhibitor and 0.08kg fluorescein Composition; Described composite corrosion inhibitor is made up of 11.3kg borax, 2.5kg sodium benzoate, 0.5kg benzotriazole, 0.23kg caustic soda, 0.08kg methyl silicone oil; Described ethylene glycol employing content is 98% Industrial grade ethylene glycol. The preparation method of the antifreeze in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com