Roller-hearth type creeper tread quenching press machine

A technology for quenching presses and track shoes, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., and can solve the problems of high critical cooling speed, large volume, and quenching failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

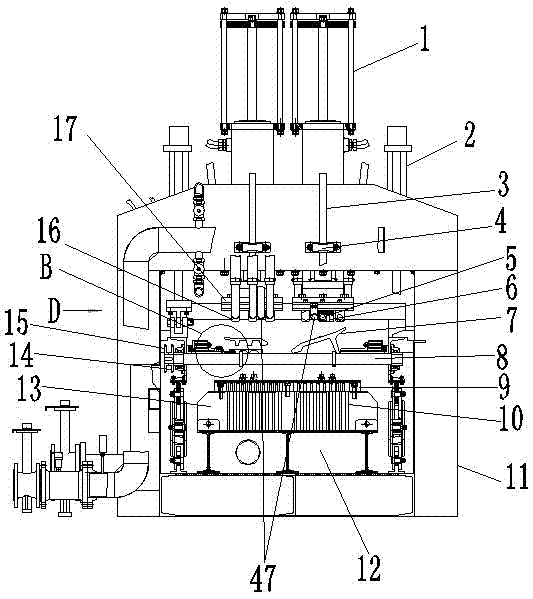

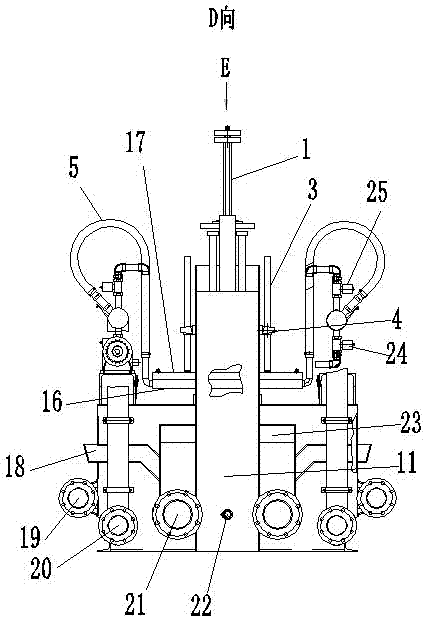

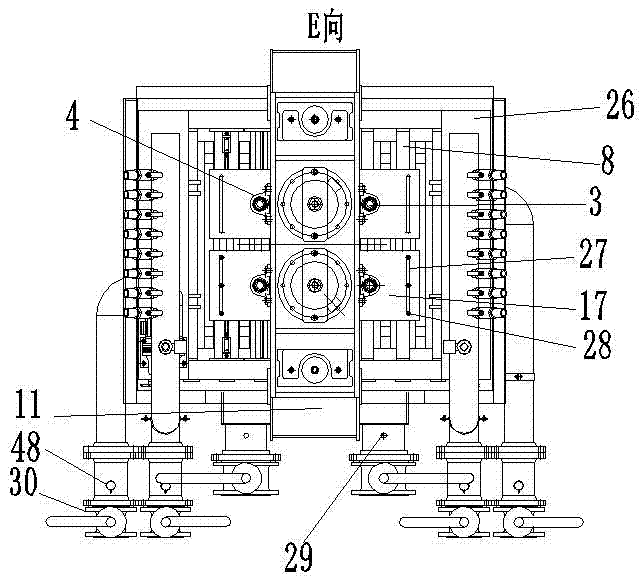

[0034] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0035]A roller bottom track shoe quenching press, as shown in the figure, it includes a frame, above which a drive roller 8 that can reciprocate up and down is installed, and the two ends of the drive roller 8 are installed on a floating bracket 26, Ten transmission rollers 8 are installed on the preferred floating support 26, the gap between adjacent transmission rollers 8 is 130-150mm, preferably 142mm, the same end of each transmission roller 8 is equipped with a roller sprocket 14, and is located in the feeding The first drive roller 8 at the end is equipped with two sprockets, one of which is used to access the motor power, that is, the drive sprocket 15, and the other sprocket is a roller sprocket 14, which is connected with the rest of the drive rollers. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com