Toughening type conductive polylactic acid fiber and preparation method and application thereof

A lactic acid fiber, conductive polymer technology, applied in conductive/antistatic filament manufacturing, melt spinning, stretch spinning, etc., can solve the problems of low breaking strength and elongation at break of conductive fibers, poor product quality, etc. Achieve the effect of improving breaking strength and elongation at break, ensuring product quality, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The toughened conductive polylactic acid fiber provided in Example 1 of the present invention is made of polylactic acid, polyamide elastomer and conductive material, and the mass ratio of the three is: polylactic acid: 60-90 parts, such as 60 parts, 63 parts , 70 parts, 80 parts, 88 parts, 90 parts, etc.; polyamide elastomer: 10~40 parts, such as 10 parts, 13 parts, 20 parts, 30 parts, 38 parts, 40 parts, etc.; conductive material: 0.1~9 parts parts, such as 0.1 parts, 0.5 parts, 1 part, 3 parts, 5 parts, 7 parts, 8 parts, 8.8 parts, 9 parts, etc.; among them, the viscosity-average molecular weight of polylactic acid is: 5×10 4 ~2×10 5 , such as 5×10 4 , 5.5×10 4 , 6×10 4 , 8×10 4 , 9×10 4 , 1×10 5 , 1.5×10 5 , 1.8×10 5 , 2×10 5 etc., the conductive material is carbon black, carbon nanotubes or graphene.

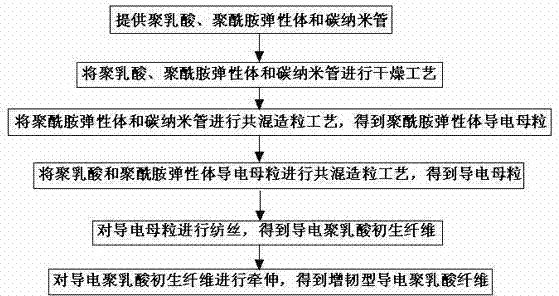

[0038] figure 1 It is a schematic flow chart of the preparation method of the toughened conductive polylactic acid fiber provided in Example 1 of the pres...

Embodiment 2

[0047] The toughened conductive polylactic acid fiber provided in Example 2 of the present invention is made of polylactic acid, polyamide elastomer and conductive material, and the mass ratio of the three is: polylactic acid: 60~90 parts, such as 60 parts, 61 parts , 73 parts, 81 parts, 89 parts, 90 parts, etc.; polyamide elastomer: 10~40 parts, such as 10 parts, 11 parts, 19 parts, 31 parts, 39 parts, 40 parts, etc.; conductive material: 0.1~9 parts parts, such as 0.1 parts, 0.2 parts, 0.8 parts, 1.3 parts, 4.5 parts, 6.7 parts, 7.8 parts, 8.9 parts, 9 parts, etc.; among them, the viscosity-average molecular weight of polylactic acid is: 5×10 4 ~2×10 5 , such as 5×10 4 , 5.1×10 4 , 6.5×10 4 , 8.3×10 4 , 9.3×10 4 , 1.1×10 5 , 1.3×10 5 , 1.9×10 5 , 2×10 5 etc., the conductive material is carbon black, carbon nanotubes or graphene.

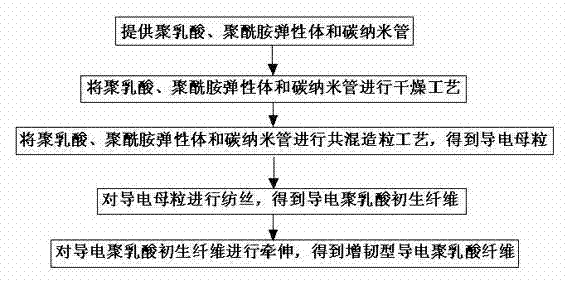

[0048] figure 2 It is a schematic flow chart of the preparation method of the toughened conductive polylactic acid fiber provided in E...

Embodiment 3

[0056] The preparation method of the toughened conductive polylactic acid fiber provided in Example 3 of the present invention comprises the following steps:

[0057] 1) Provide 70 parts of polylactic acid, 30 parts of polyamide elastomer and 5 parts of carbon nanotubes.

[0058] 2) Dry 70 parts of polylactic acid in a vacuum oven at 90°C for 20 hours, dry 30 parts of polyamide elastomer in a vacuum oven at 65°C for 20 hours, and dry 5 parts of carbon nanotubes The drying process was performed in a vacuum oven at 100°C for 10 hours.

[0059] 3) Put polylactic acid, polyamide elastomer and carbon nanotubes into a high-speed mixer for 8 minutes of mixing operation, and then blend and granulate in a twin-screw blender. The granulation temperature is 200°C and the screw speed is 70rmp. Melt blending time is 10 minutes, obtains conductive masterbatch;

[0060] 4) Spin the conductive masterbatch on a melt spinning machine at a temperature of 230°C to obtain conductive polylactic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com