Wedge-shaped concrete cushion block for long-span steel structure bridge incremental launching construction

A concrete and concrete reinforcement technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large waste, insufficient bearing capacity, accidents, etc., and achieve the effects of reduced engineering cost, simple production, and flexible and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

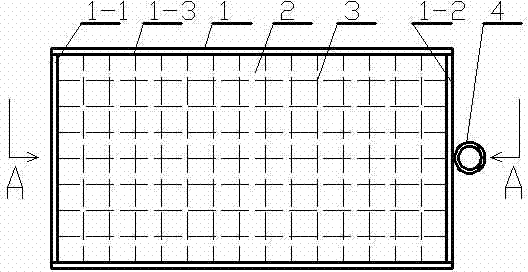

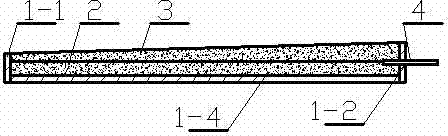

[0016] In the accompanying drawings, a concrete wedge-shaped pad for pushing construction of a long-span steel structure bridge includes a steel frame 1, a double-layer steel mesh sheet 2, a concrete reinforcement layer 3 and a suspension ring 4; the concrete wedge-shaped pad has a wedge-shaped steel Frame 1, the steel frame 1 is laid with a double-layer steel mesh 2, and the double-layer steel mesh 2 is welded and fixed to the steel frame 1; a flat concrete reinforcement layer 3 is poured in the steel frame 1, and the The thickness of the concrete reinforcement layer 3 is equal to the depth of the steel frame 1; one side of the steel frame 1 is fixedly connected with a suspension ring 4.

[0017] The size of the concrete wedge block is: length 700-900 mm, width 500-700 mm, the minimum thickness of the wedge block is 30 mm, the maximum thickness is 80-300 mm, and the block is smooth and flat.

[0018] The steel frame 1 is welded by steel plates with a thickness of 1-2 mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com