Exhaust steam recycling heating device for waste heat power generation deaerator

A technology of waste heat power generation and heating device, which is applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve problems such as poor thermal economy, and achieve the effects of small vibration, improved energy utilization, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

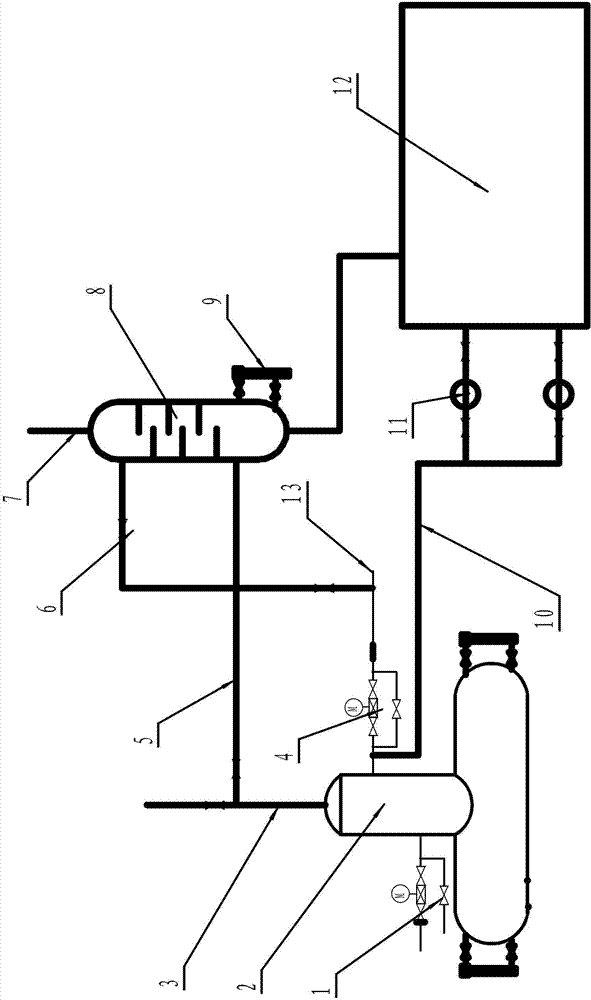

[0035] Example 1, a waste heat power generation deaerator exhaust steam recovery heating device, including a deaerator 2, the deaerator is connected to the steam pipeline through the deaerator inlet valve 1 with a steam flow meter, and the top of the deaerator is equipped with The deoxygenation exhaust pipe 3 with valve is characterized in that: the valve of the deoxygenation exhaust pipe is provided with a deaerator exhaust pipe 5 connected to the lower part of the disc-type soda-water mixing heater 8, and the disc-type soda-water The upper part of the hybrid heater is connected to the desalted water pipeline 13 equipped with the desalted water inlet valve 6 for the heater. The top of the disc-type steam-water mixed heater is provided with a non-condensable gas discharge pipe 7, and the bottom is provided with a pipe connected to the drain tank 12. The drain tank A drain pipe 10 on which a drain pump 11 is installed is connected to the deaerator. Described deaerator is provid...

Embodiment 2

[0037] Example 2, a waste heat power generation deaerator exhaust steam recovery heating device, including a deaerator 2, the deaerator is connected to the steam pipeline through the deaerator inlet valve 1 with a steam flow meter, and the top of the deaerator is equipped with The deoxygenation exhaust pipe 3 with valve is characterized in that: the valve of the deoxygenation exhaust pipe is provided with a deaerator exhaust pipe 5 connected to the lower part of the disc-type soda-water mixing heater 8, and the disc-type soda-water The upper part of the hybrid heater is connected to the desalted water pipeline 13 equipped with the desalted water inlet valve 6 for the heater. The top of the disc-type steam-water mixed heater is provided with a non-condensable gas discharge pipe 7, and the bottom is provided with a pipe connected to the drain tank 12. The drain tank A drain pipe 10 on which a drain pump 11 is installed is connected to the deaerator. Described deaerator is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com