Array substrate, display device and manufacturing method of array substrate

An array substrate and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor display effect, achieve the effects of reducing jump voltage, improving display effect, and reducing capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

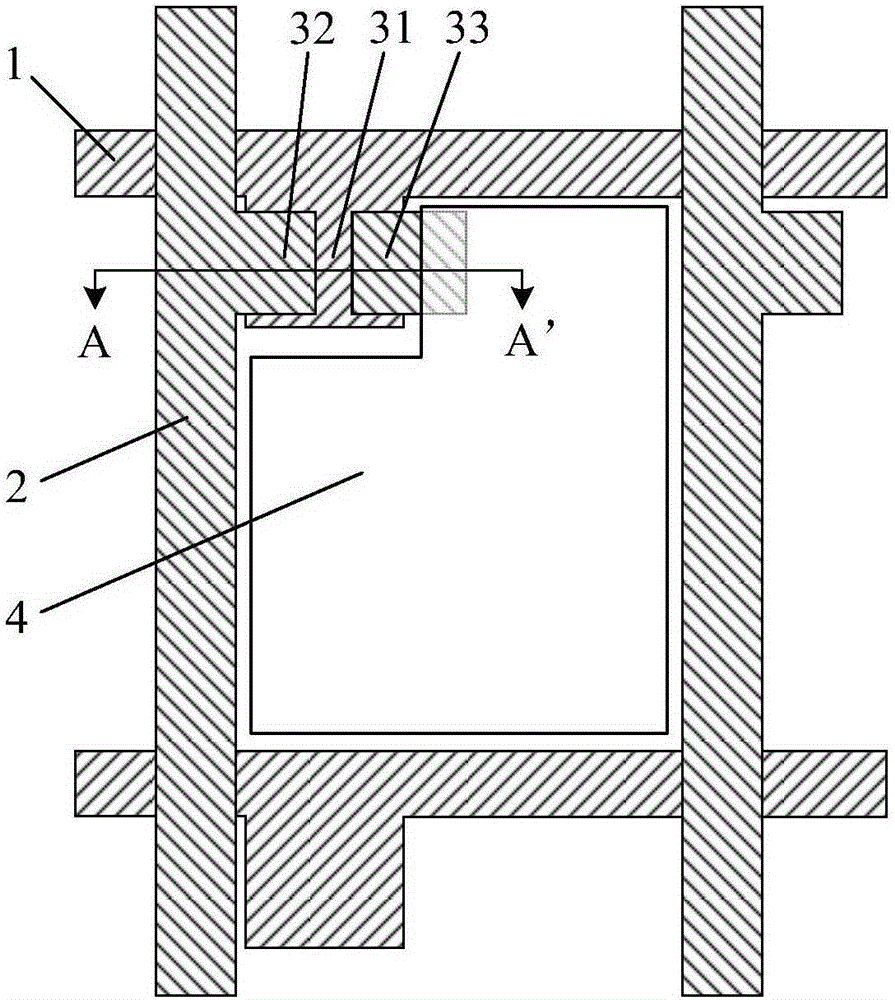

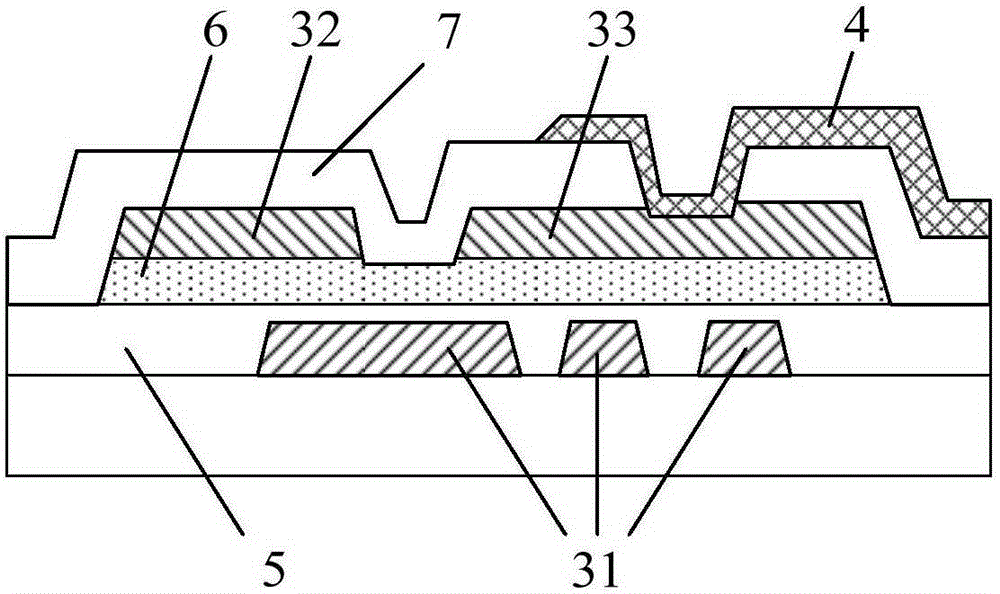

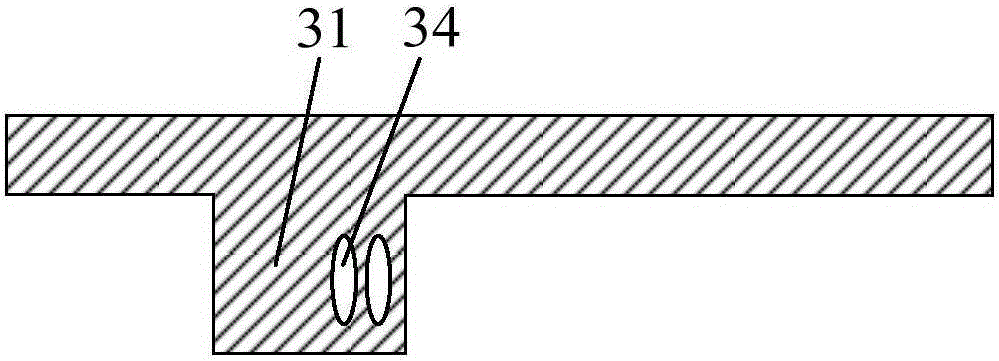

[0029] like figure 1 and figure 2 As shown, this embodiment provides an array substrate, including gate lines 1, data lines 2, thin film transistors and transparent electrodes 4, the thin film transistors include a gate 31, a source 32 and a drain 33, the gate of the above thin film transistor 31 is connected to the gate line 1, the source 32 of the thin film transistor is connected to the data line 2, and the drain 33 of the thin film transistor is connected to the transparent electrode 4, as figure 2 and image 3 As shown, a gate through hole 34 is provided in a region overlapping the drain 33 on the gate 31 . The number, size and shape of the gate through holes 34 are not limited in this implementation.

[0030] In the array substrate in this embodiment, a gate through hole is provided on the gate in the overlapping region of the gate and the drain of the thin film transistor, which reduces the overlapping area of the gate and the drain, thus reducing the gap between...

Embodiment 2

[0032] like Figure 4 As shown, this embodiment provides an array substrate, including a gate line, a data line, a thin film transistor and a transparent electrode 4, the gate 31 of the thin film transistor is connected to the gate line, and the source 32 of the thin film transistor is connected to the data line. line, the drain 33 of the thin film transistor is connected to the transparent electrode 4, the gate 31 includes a first region, the thickness of the gate 31 in the first region is smaller than the thickness of the gate 31 outside the first region, and the first region is located In the overlapping region of the gate 31 and the drain 33 . It should be noted that, this embodiment does not limit the shape of the first region. For example, the area of the first region may be very small, which is equivalent to an unpenetrated through hole; the first region may also be divided into multiple region blocks, and these region blocks may be in the shape of bars, circles, and...

Embodiment 3

[0036] This embodiment provides a display device, including the array substrate in Embodiment 1 or Embodiment 2.

[0037] In the display device in this embodiment, a gate through hole is provided on the gate in the overlapping region of the gate and the drain of the thin film transistor to reduce the area where the gate and the drain overlap, or the gate and the drain overlap The thickness of the gate in the first region is reduced to increase the distance between the gate and the drain in the overlapping region, thereby reducing the capacitance value of the parasitic capacitance formed between the gate and the drain, and reducing the generation of parasitic capacitance The jump voltage, thus improving the display effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com