Remote monitoring system and method for coke oven vehicle equipment

A remote monitoring system and vehicle technology, which is applied to the remote monitoring system and monitoring field of coke oven vehicle equipment, can solve the problems of not being able to remote control, no data collection and data processing of coke oven vehicle equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

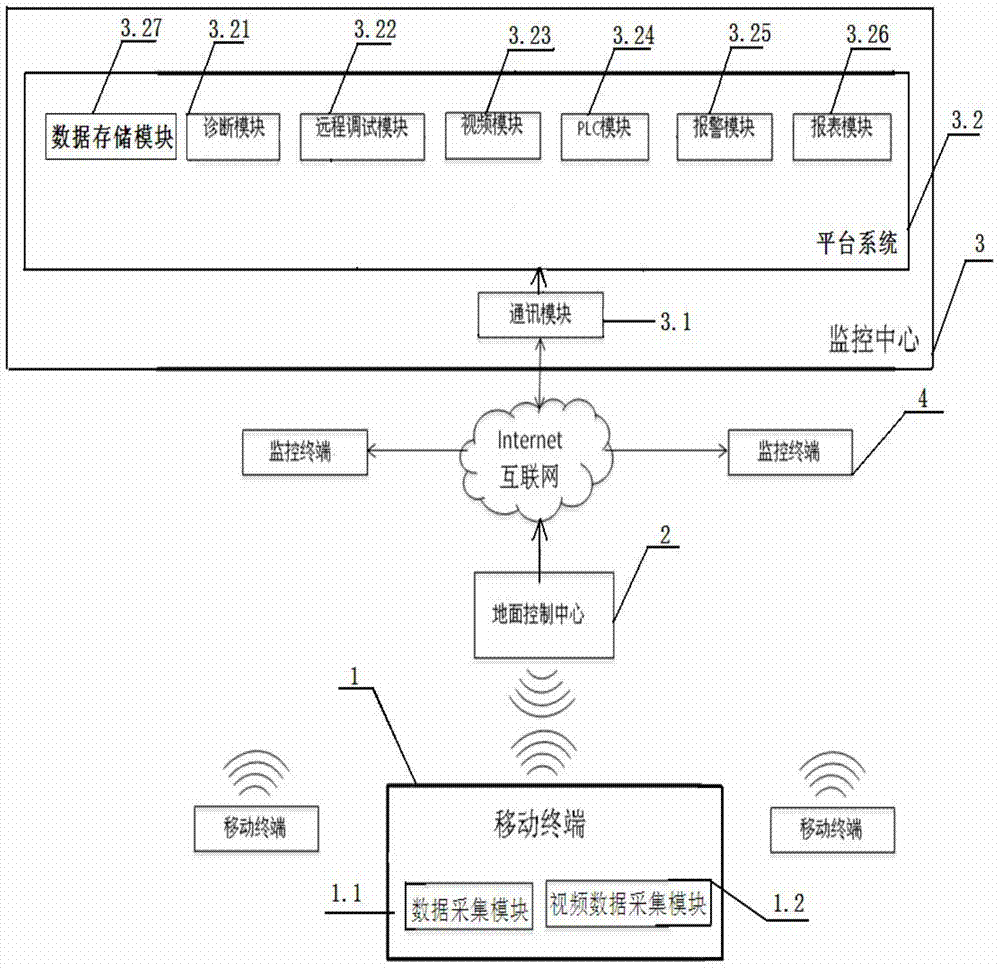

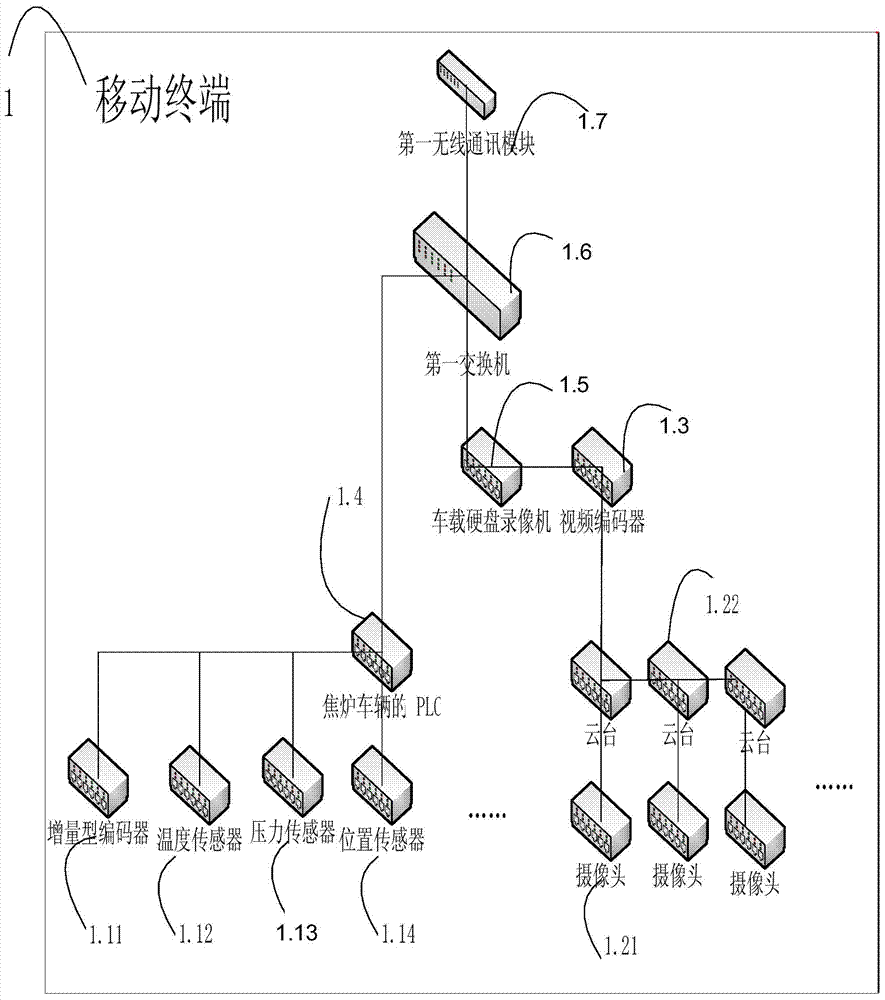

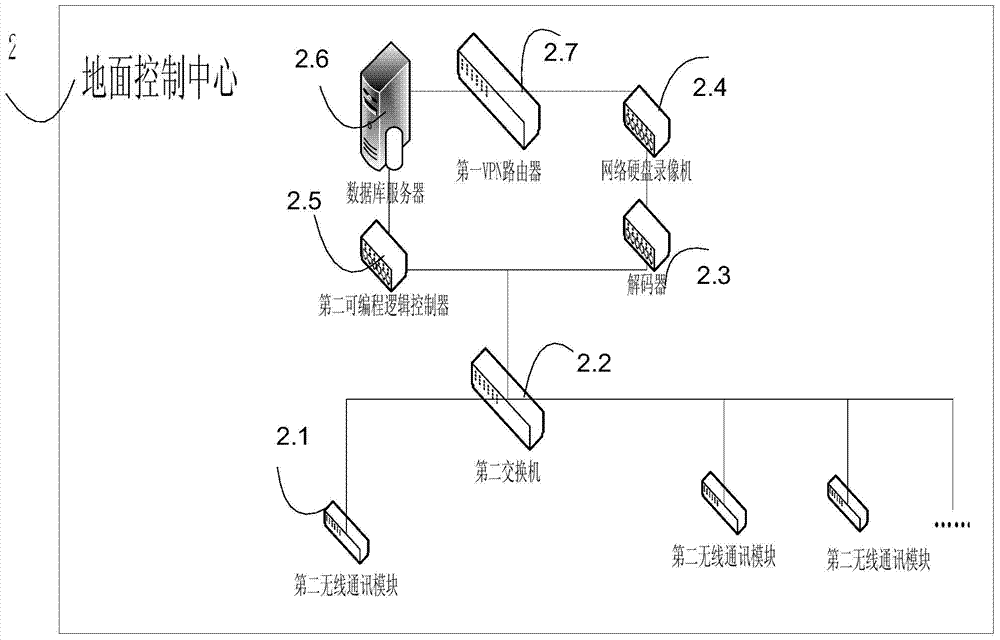

[0046] In actual field work, the coke oven vehicle equipment remote monitoring system uses multiple electrical equipment, such as figure 1 , figure 2 and image 3 As shown, the monitoring system has multiple mobile terminals 1, and the data acquisition module 1.1 in the mobile terminal 1 includes an incremental encoder 1.11, a temperature sensor 1.12, a pressure sensor 1.13 and a position sensor 1.14 installed on the coke oven vehicle, and the video The data acquisition module 1.2 includes a plurality of cameras 1.21 installed on the cloud platform. Use the incremental encoder 1.11 to collect the travel and coke pushing distance of the coke oven vehicle, use the temperature sensor 1.12 to detect the actual working temperature of the hydraulic oil in the hydraulic system during the operation of the coke oven vehicle equipment, and use the pressure sensor 1.13 to detect the operation of the coke oven vehicle equipment The actual working pressure of the hydraulic system in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com