Visual guidance welding robot weld joint fast recognition technology based on double dynamic windows

A welding robot and vision-guided technology, applied in welding equipment, auxiliary welding equipment, character and pattern recognition, etc., can solve the problems of large data volume, affecting the real-time performance of the weld seam tracking system, etc., and achieve the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the following is the specific implementation process, and with reference to the accompanying drawings, the present invention will be further described in detail.

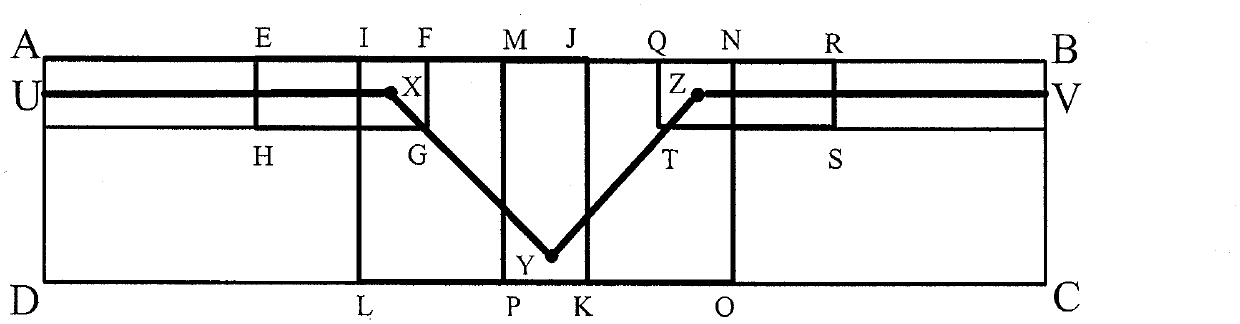

[0016] The basic idea of the present invention is: structured light V-shaped welds generally adopt the method of windowing the entire image to intercept the ROI area, and then process the intercepted area to reduce the amount of data and improve real-time performance. Disadvantages: On the basis of the first layer of dynamic windowing, dynamic windowing of small window images is considered again to reduce the amount of Hough transform data processing, so as to improve the speed of Hough transform, improve the overall processing efficiency, and improve real-time performance.

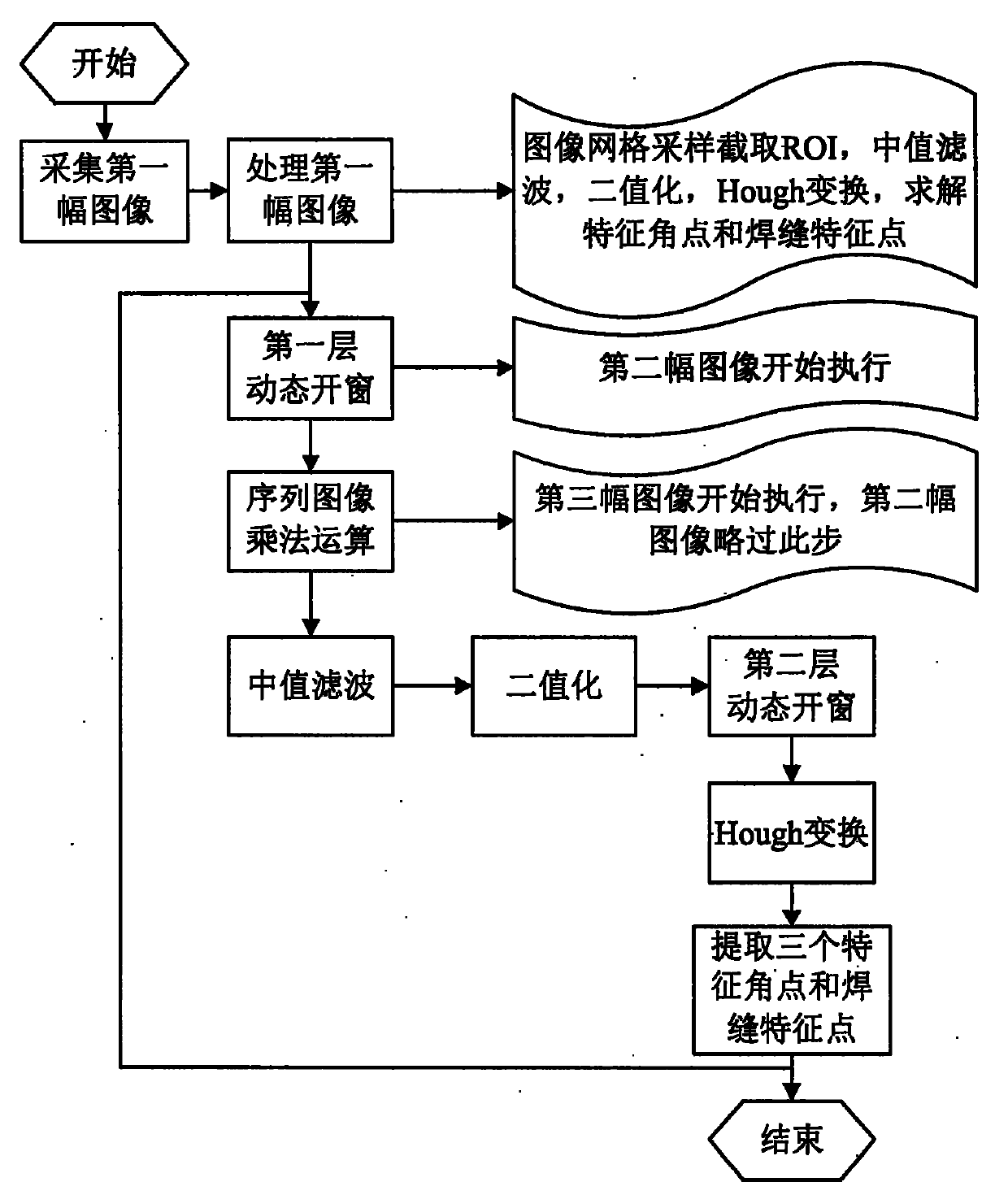

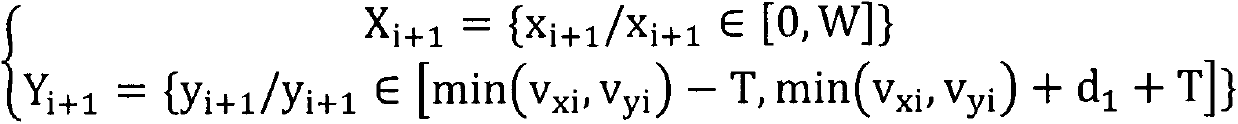

[0017] attached figure 1 , is the processing flow chart of the present invention. Firstly, the first image collected is processed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com