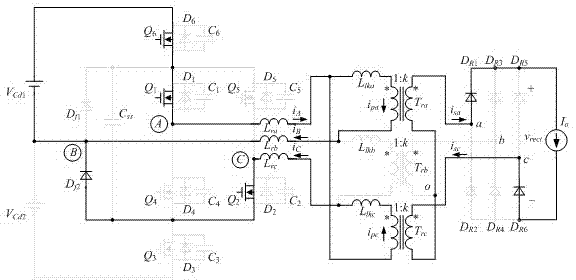

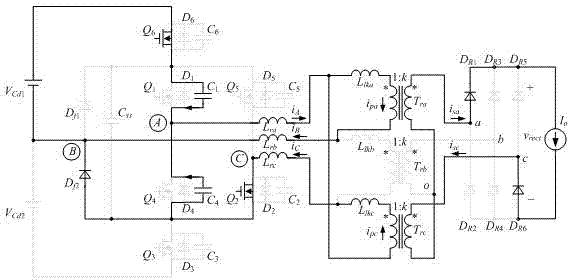

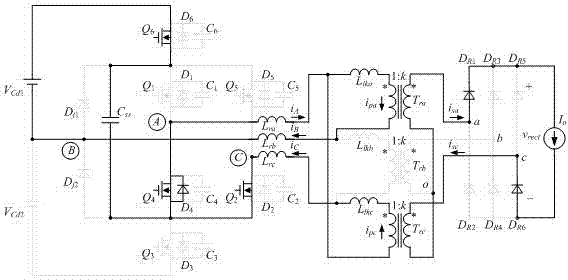

Method for asymmetrically controlling simplified-type three-phase three-level direct-current converter

A converter, a half-bridge three-level technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve problems such as unguaranteed and large switching losses, and achieve voltage, Realize the effect of zero voltage switching and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0057] A specific embodiment of the present invention: input DC voltage: Vin=540~660V; output DC voltage: Vo=48V; output current: Io=20A; three-phase transformer primary side transformation ratio is 1:9; output filter inductance: Lf=22uH; MOSFET (Q1-Q6): IPW65R080CFD; freewheeling diode (Df1, Df2): DSEI30-06A; secondary rectifier diode (DR1-DR6): DSEP30-03A; switching frequency: fs=50kHz.

[0058] Figure 17~Figure 20 The driving voltages V of the switching tubes Q2 and Q5 when Vin is 540V and 660V and the output is fully loaded are given respectively. GS , drain-source voltage V DS and drain current I D At this time, the converter works in medium duty cycle mode and small duty cycle mode respectively. It can be seen from the figure that the voltage stress of all switching tubes is half of the input voltage. Before the switching tube is turned on, there is a reverse current in the drain, that is, the reverse parallel diode is turned on, and the voltage at both ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com