Lateral inlet air flow equalization device

A technology of bag filter and dust collector, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc. It can solve the problems of strong scouring of filter bags, easily damaged filter bags, and weak collection of large particles. , to achieve the effect of weakening the secondary back-mixing, prolonging the life, and improving the intake airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

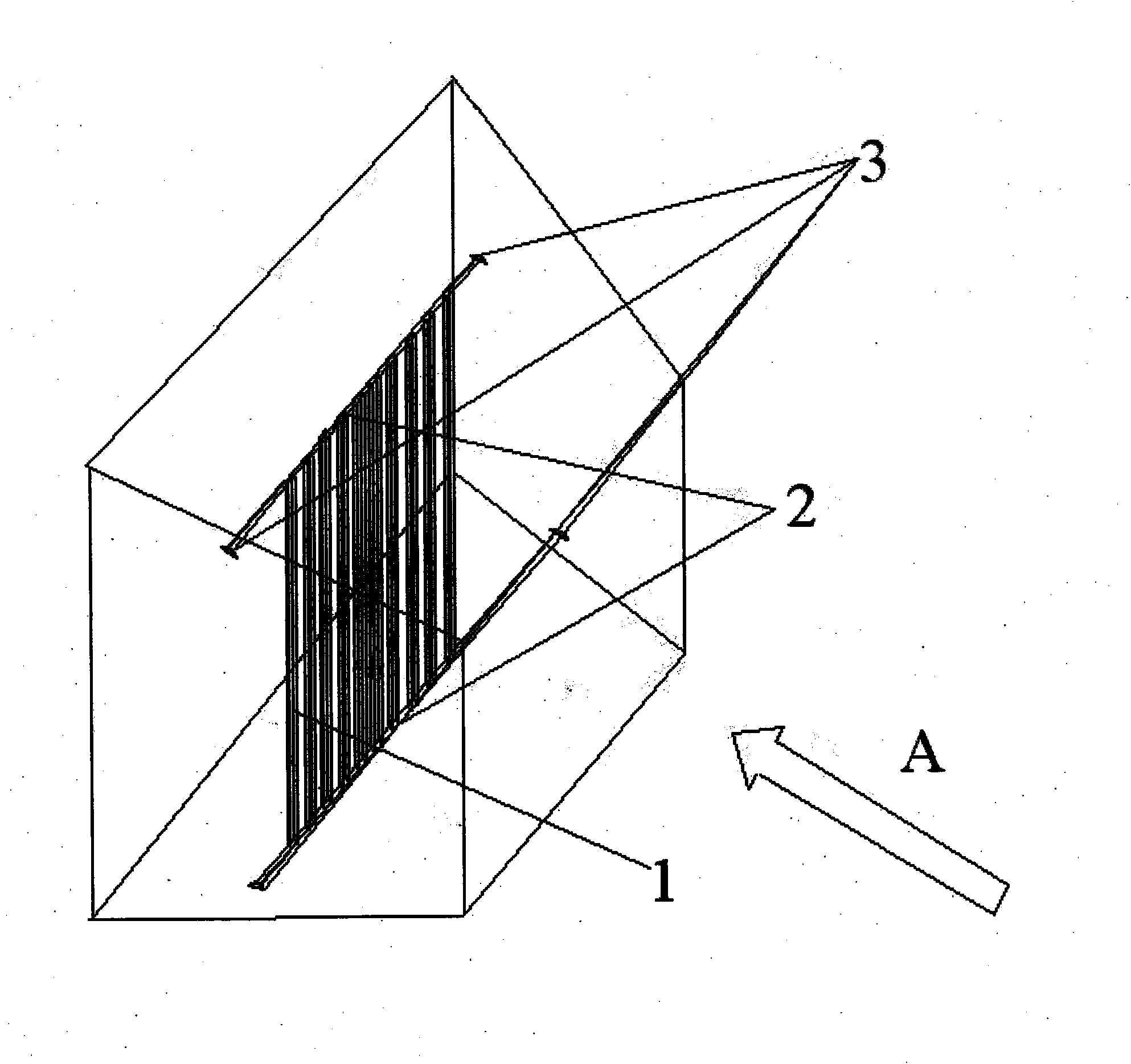

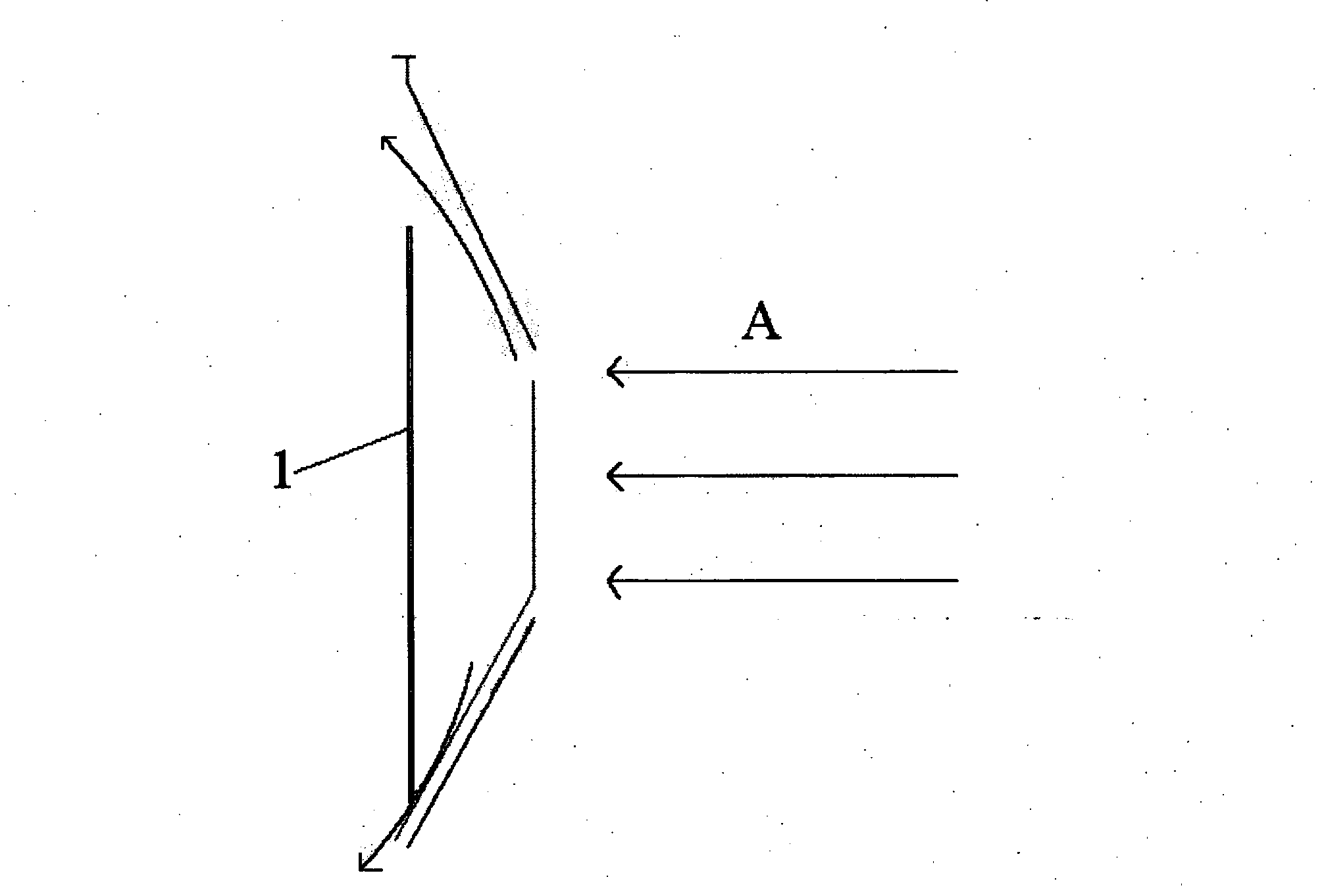

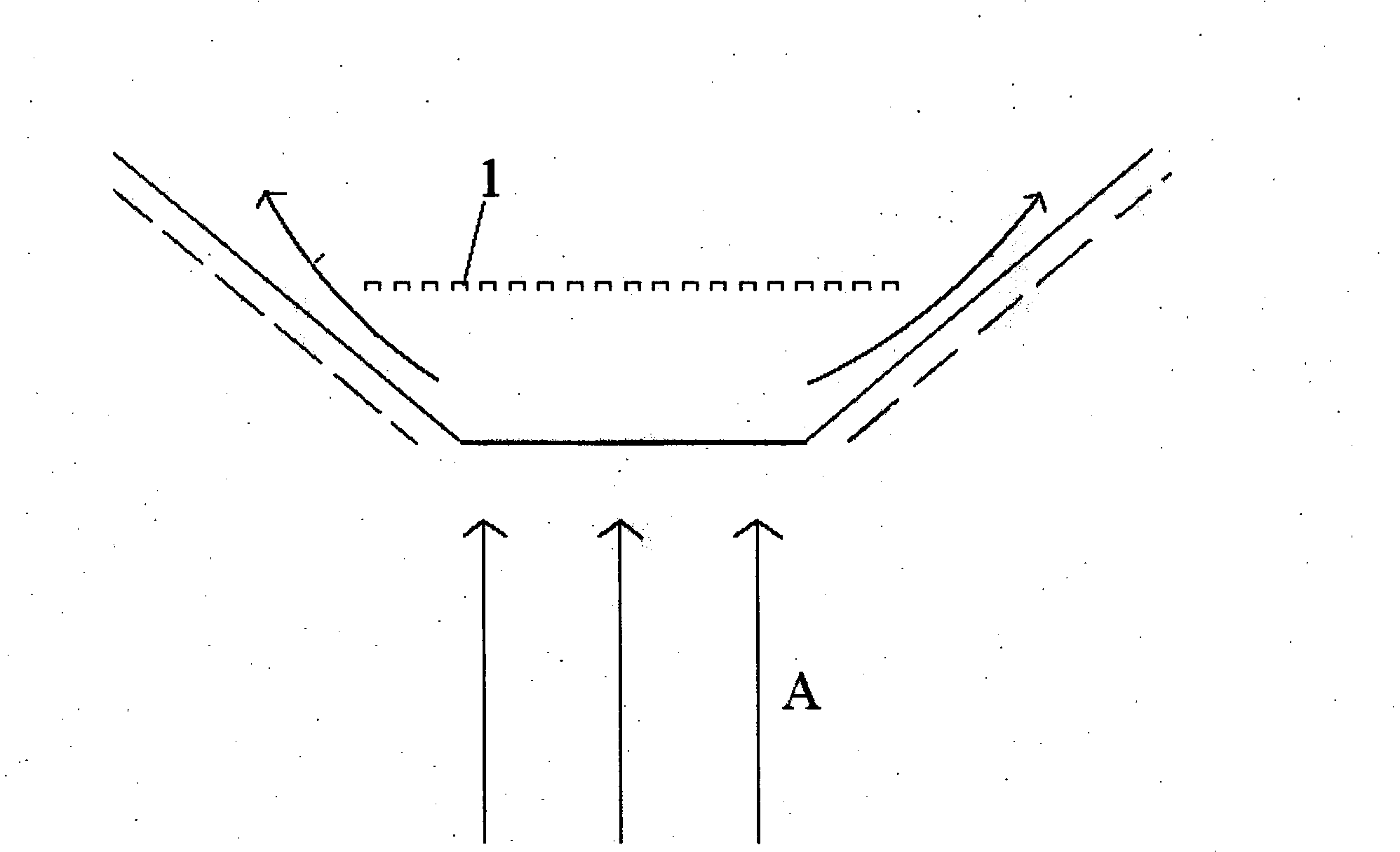

[0021] figure 1 Schematic diagram of the side air inlet flow equalization device of the bag filter provided by the present invention, the side air inlet flow equalization device of the bag filter includes a series of channel steel 1, two steel plates used to fix the channel steel 1 2, and welding angle seat 3. Two steel plates 2 are laterally fixed on the two side walls of the air inlet flue of the dust collector through welding angle seats 3 . Welding angle seat 3 is to make with angle steel, in order to support two steel plates 2. The channel steel 1 is fixed on the upper and lower two steel plates 2, and the channel steel 1 is arranged side by side in a row, and the number of rows arranged can be designed according to specific conditions.

[0022] figure 1 Middle A is the air intake direction, and the device provided by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com