Atomization ejection device and method for SNCR (Selective Non Catalytic Reduction) denitration

An injection device and denitrification technology, applied in the field of atomization injection device and circulating fluidized bed boiler, can solve the problems of reducing atomization quality, affecting denitration efficiency, reducing denitration efficiency, etc., and achieving obvious heating effect, uniform injection effect, and improved The effect of denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

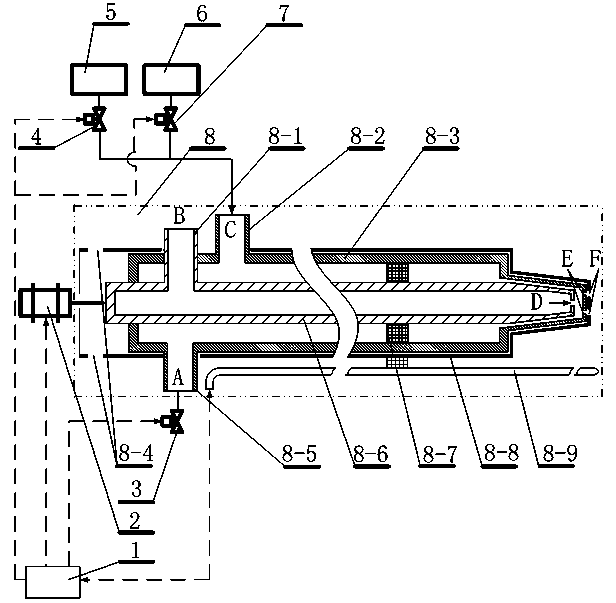

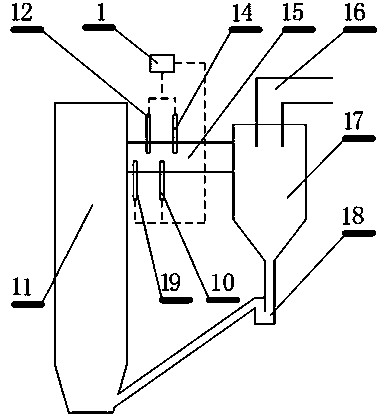

[0023] see figure 1 , a device for the atomization injection method of SNCR denitrification, including a PID control module 1, a motor 2, a drain valve 3, a solution valve 4, a liquid storage tank 5, a cooling water tank 6, a cooling water valve 7, and a spray gun 8.

[0024] The output end of the PID control module 1 is respectively connected with the input ends of the motor 2, the drain valve 3, the solution valve 4 and the cooling water valve 6, and the input end of the PID control module 1 is connected with the output ends of the temperature measuring devices 8-9.

[0025] The spray gun 8 includes an air intake pipe 8-1, a liquid inlet pipe 8-2, a solution pipe 8-3, a motor linkage hole 8-4, a liquid discharge pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com