Process for cavitation repair welding of through-flow turbine set runner chamber

A runner chamber and cavitation technology, applied in the direction of turbines, mechanical equipment, manufacturing tools, etc., can solve the problems of inaccurate control, large thermal deformation of the runner chamber, damage, etc., to ensure welding quality, improve working strength and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention discloses a cavitation welding repair process for a runner chamber of a tubular unit, the steps of which are as follows:

[0033] A. Determine the cavitation location of the runner chamber;

[0034] B. Plan the shape of some cavitation parts that need to be polished according to the cavitation parts;

[0035] C. Grinding according to the planned shape, the depth of grinding is consistent with the depth of cavitation, forming a grinding groove;

[0036] D. Insert a stainless steel plate that matches the shape and depth of the planned grinding part into the grinding tank; the stainless steel plate is processed with multiple sieve holes that pass through the stainless steel plate;

[0037] E. Using the argon arc welding process, the welding repair is carried out from the screen hole in the middle of the stainless steel plate to the direction of both sides, and finally the joint between the stainless steel plate and the grinding groove is welded, and the stai...

Embodiment approach

[0039] The best implementation method of the present invention is as follows:

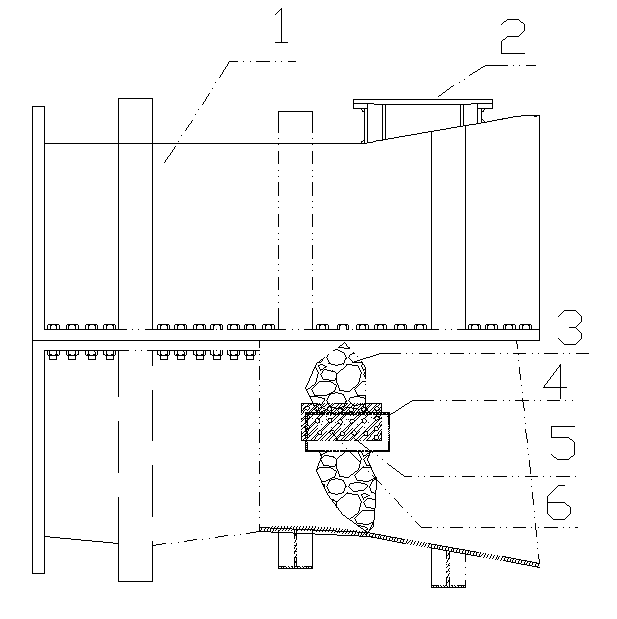

[0040] The accompanying drawings are described in detail as follows: 1 mentioned in the figure is the runner chamber of the tubular water turbine, which is located in the corridor of the hydropower station unit.

[0041] 2 in the figure is the inlet hole of the runner chamber of the tubular water turbine, which is the passage for the staff to enter the interior of the runner chamber after the flow channel of the unit has been drained.

[0042] 3 in the figure is the situation that the runner chamber of the tubular turbine is subjected to cavitation damage in different degrees during operation.

[0043] 4 in the figure is to analyze the situation of 3 in the figure, plan the scope of grinding according to the actual situation, and use a grinder to grind by hand within the grinding range, and polish the runner chamber according to the planned length, width and depth requirements. cavitation part.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com