New version roller for laser seamless double film press

A technology of no plate seam and film press machine, applied in the field of plate rolls, can solve the problems of complex sealing process of plate rolls, short service life of plate rolls, and influence on product quality, and achieve low working costs, slow heat loss, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

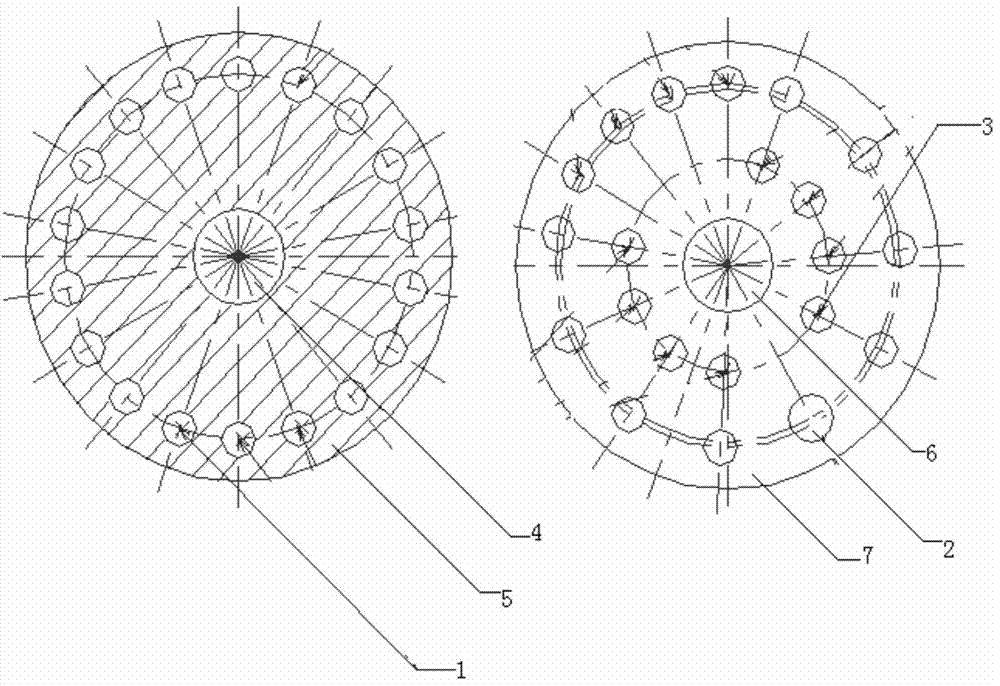

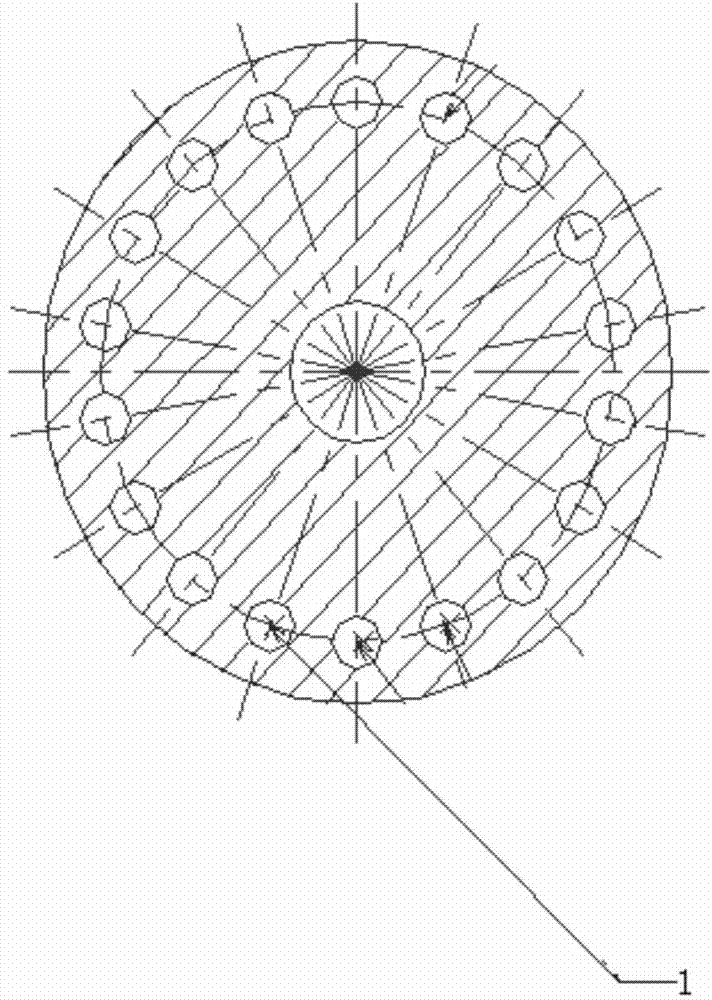

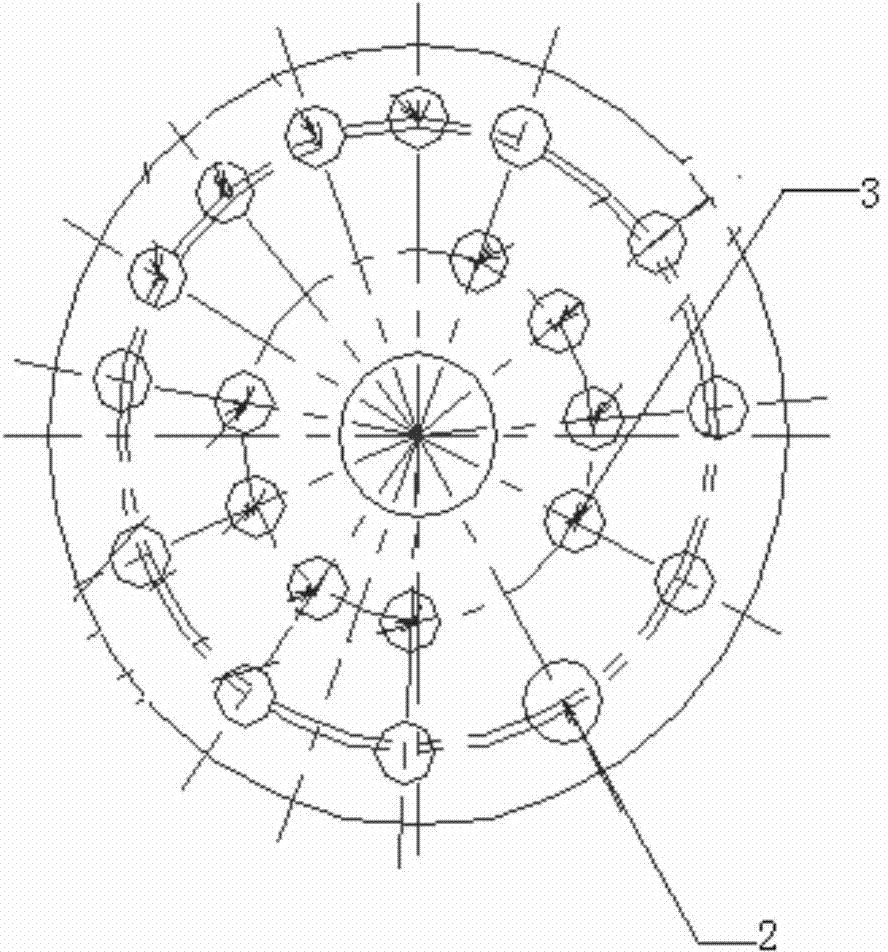

[0080] Supplied with plate rolls such as Figure 1-3 As shown in , the version roll includes Ⅰ version roll and Ⅱ version roll;

[0081] Among them, the version I roll includes: 1 first shaft hole and 18 oil through holes, among which, among the 18 oil through holes, 3 adjacent oil through holes can be selected to pass through cold oil, and the remaining 15 through heat oil;

[0082] Roller II includes a second roller body, 8 hot oil holes and 13 molded oil holes, among which, hot oil passes through the hot oil holes, and 4 adjacent molded oil holes can be selected to pass through the 13 molded oil holes. Cold oil, and the remaining 9 molded oil holes are used for hot oil.

[0083] Among them, the shortest distance between any two adjacent oil holes on the I version roller is 1.5 times the diameter of the oil hole (1);

[0084] The shortest distance between the oil hole and the first shaft hole on the roller I is 3 times the diameter of the oil hole; the shortest distance be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap