Brown glass and preparation method thereof

A glass and brown technology, applied in the field of brown glass and its preparation, can solve the problems of affecting the color of the brown glass, affecting the anti-ultraviolet function of the brown glass, etc., to achieve good product quality, increase the content of Fe3+ and S2- ions, and increase the degree of redness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0085] Specifically, the first embodiment of the brown glass of the present invention, the main raw material formula of the brown glass is as follows in parts by mass:

[0086] Quartz sand 150~250

[0087] Soda ash 35~60

[0088] Calcite 40~70

[0089] Glauber's salt 1.5~5

[0090] Iron red 0.1~2

[0091] Toner 0.5~3

[0092] Copper oxide 0.3 ~2.

[0093] Preferably, in the first embodiment of the brown glass of the present invention, its main raw material formula in parts by mass is as follows:

[0094] Quartz sand 160~200

[0095] Soda ash 40~55

[0096] Calcite 50~60

[0097] Glauber's salt 2~4

[0098] Iron red 0.1~1

[0099] Toner 0.5~2

[0100] Copper oxide 0.5 ~0.8.

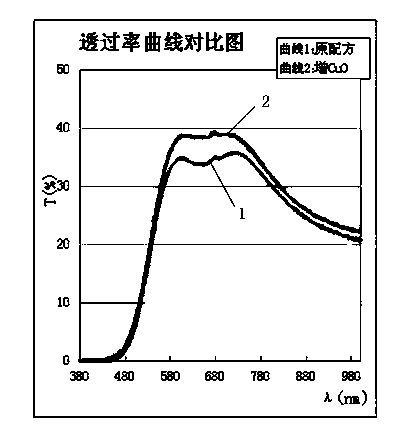

[0101] Introduce copper oxide into the brown glass formula raw material, and use Cu in different states in the glass: Cu 0 Make the glass red, Cu + Make the glass red, Cu 2+ Makes glass appear azure. The brown glass of bottles and jars is reducing glass. After adding CuO to the formula raw ...

no. 3 example

[0131] Preferably, in the third embodiment of the brown glass of the present invention, its main raw material formula in parts by mass is as follows:

[0132] Quartz sand 160~200

[0133] Soda ash 40~55

[0134] Calcite 50~60

[0135] Glauber's salt 4.5~6

[0136] Iron red 0.1~1

[0137] Toner 0.5~2

[0138] Copper oxide 0.4~0.6.

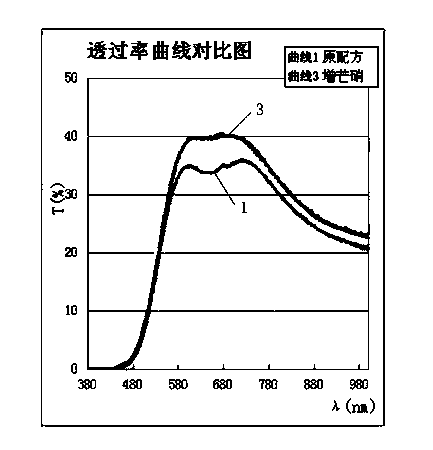

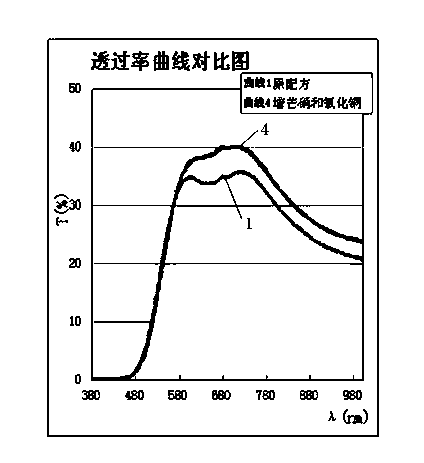

[0139] Introducing copper oxide and increasing the amount of Glauber's salt in the brown glass formula raw materials can significantly increase the red ratio of the brown glass and improve product quality.

[0140] It should be noted that the main raw material formula of the brown glass is 1000 parts by mass of various raw material dosages of molten glass.

[0141] The raw material of the brown glass also includes cullet, wherein cullet accounts for 65-85%, that is, cullet accounts for 650-850 parts.

[0142] Preferably, the cullet accounts for 75%.

[0143] Below with specific embodiment I to IV the raw material formula of brown glass of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com