Cathode material of lithium and its production method

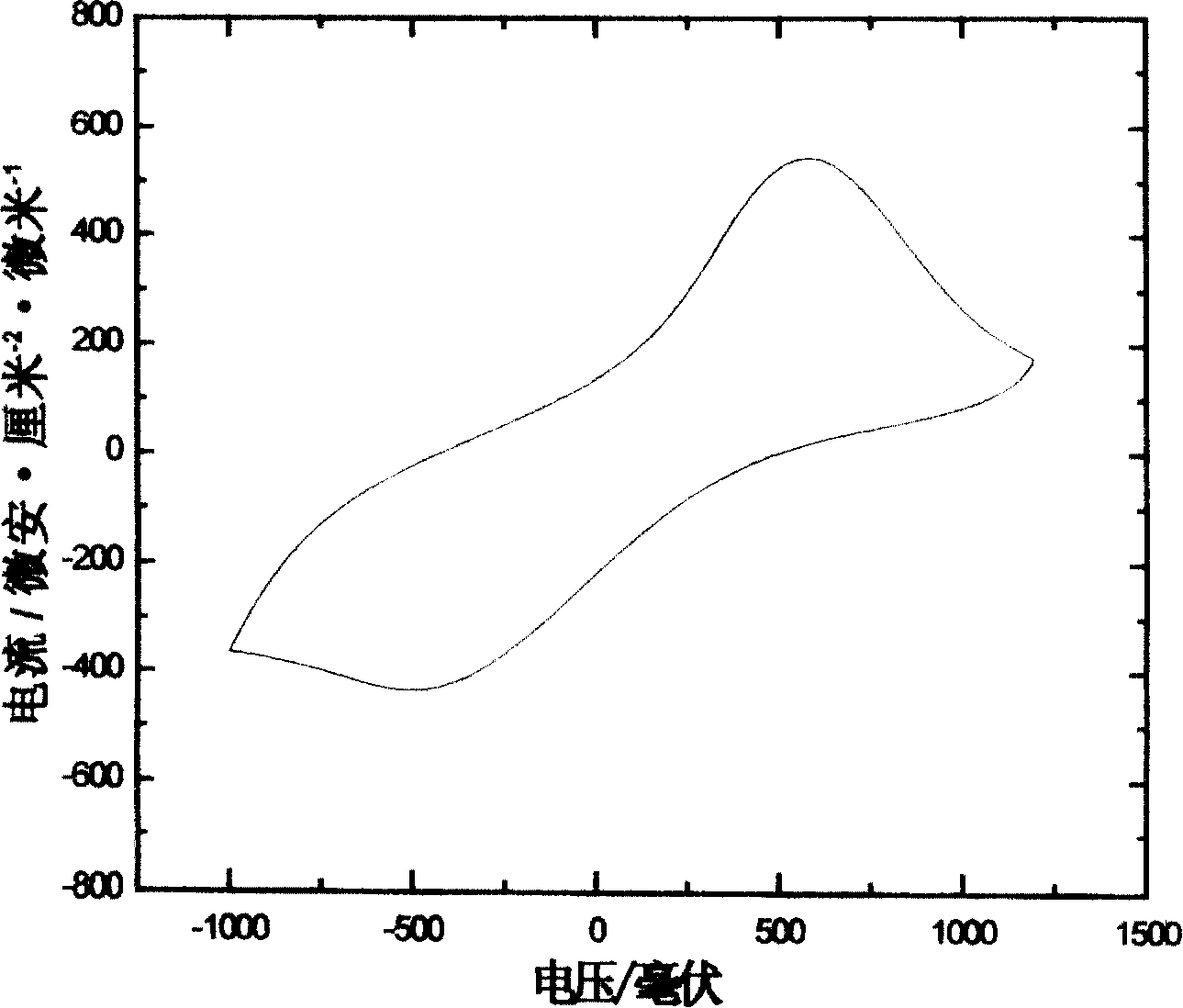

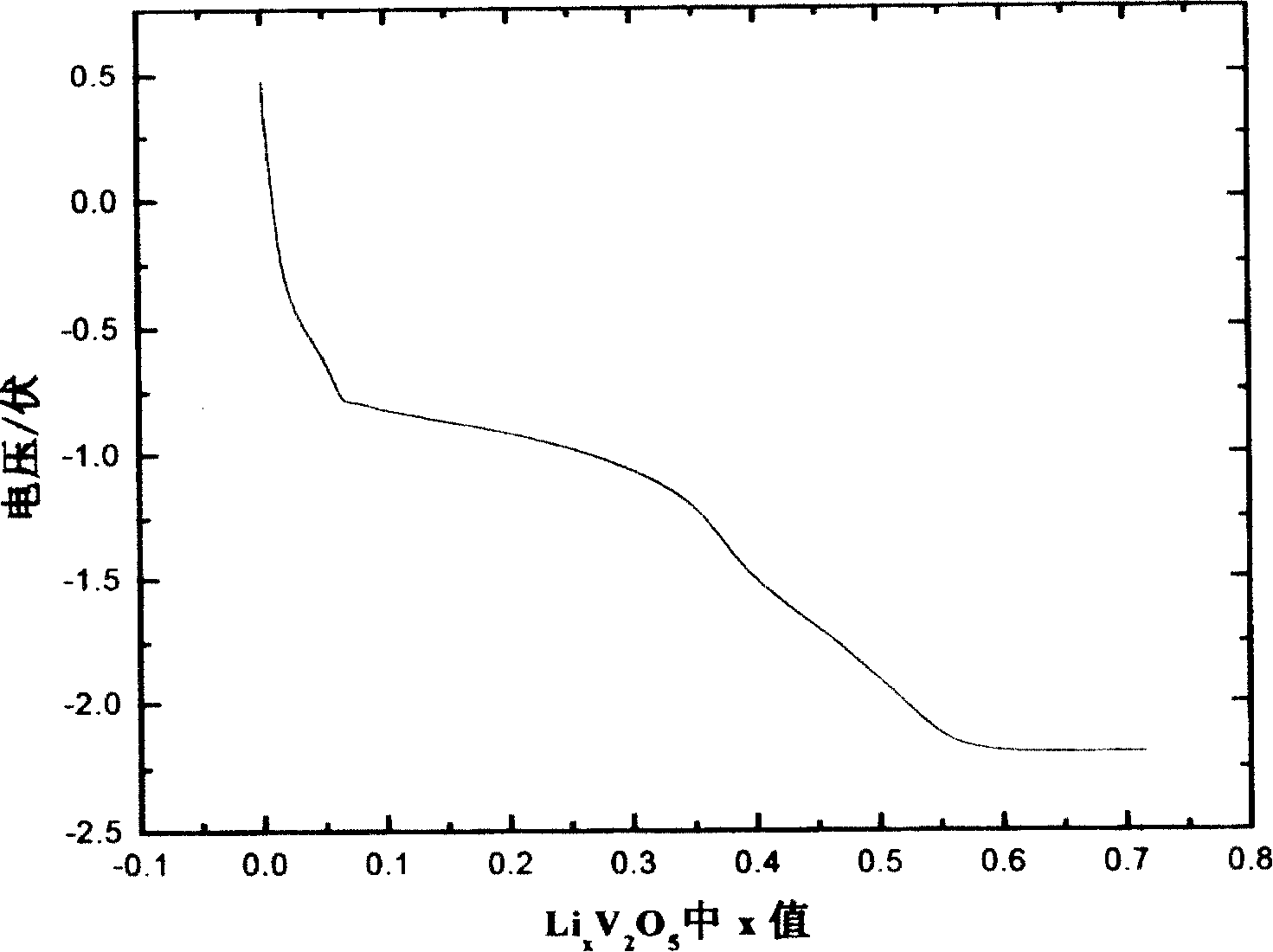

A cathode material, lithium battery technology, applied in the direction of electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problem of low porosity, and achieve the effects of good cycle durability, uniform film thickness, and large charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention and its beneficial effects are further described below through the embodiments and accompanying drawings.

[0027] A preparation method for lithium battery cathode material, comprising the following steps,

[0028] 1. V 2 o 5 Sol preparation

[0029] Preparation of V by sol-gel method 2 o 5 Sol, the V 2 o 5 Powder, benzyl alcohol and isopropanol or isobutanol were mixed in a molar ratio of 1:4:40, refluxed at 110°C for 5 hours, and then centrifuged at 3000 rpm for 30 minutes to remove unreacted residual substances , to get a dark green opaque V 2 o 5 The sol was then aged in an oven at 50°C for 3 days, and centrifuged at 3000 rpm for 20 minutes to obtain a yellow-green transparent V 2 o 5 Sol.

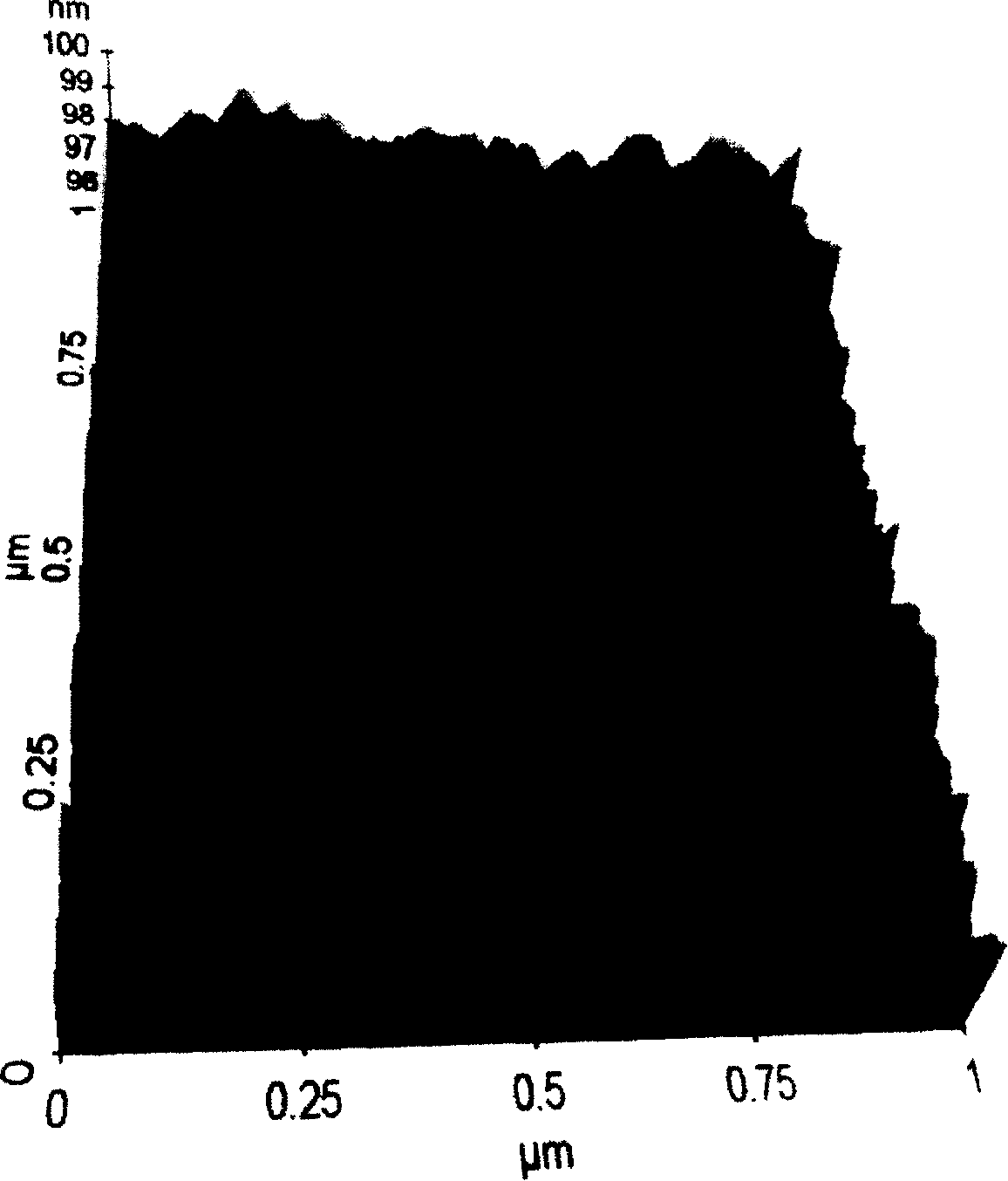

[0030] 2. Preparation of thin film materials

[0031] 1) Substrate processing

[0032] Using ITO conductive glass as the substrate, the cleaning steps of the substrate are as follows: put the conductive glass into the ultrasonic cleaning pool, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com