Preparation method of organic dopant DMAI in efficient inorganic CsPbI3 perovskite

A perovskite and dopant technology, which is applied in the field of N,N-dimethylammonium iodide preparation, can solve the problems of reducing the photoelectric conversion efficiency of perovskite cells, increasing grain boundaries, etc., so as to improve the photoelectric conversion efficiency, Effects of high crystallinity, improved stability and optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. Add 20ml of hydroiodic acid solution to 20ml of N,N-dimethylformamide solution to form a mixed solution, stir at low temperature for 4h, and mark it as solution A.

[0028] b. Rotate solution A in a water bath at 90°C for 3 hours, until it becomes viscous;

[0029] c. Dissolve the viscous substance in 50ml of ethanol to form a clear solution B;

[0030] d. Add 250ml of diethyl ether into solution B, extract the precipitate, and mark it as C precipitate;

[0031] e. heat-treat the C precipitate prepared above in an oven at 40° C. for more than 4 hours to obtain DMAI powder with high crystallinity.

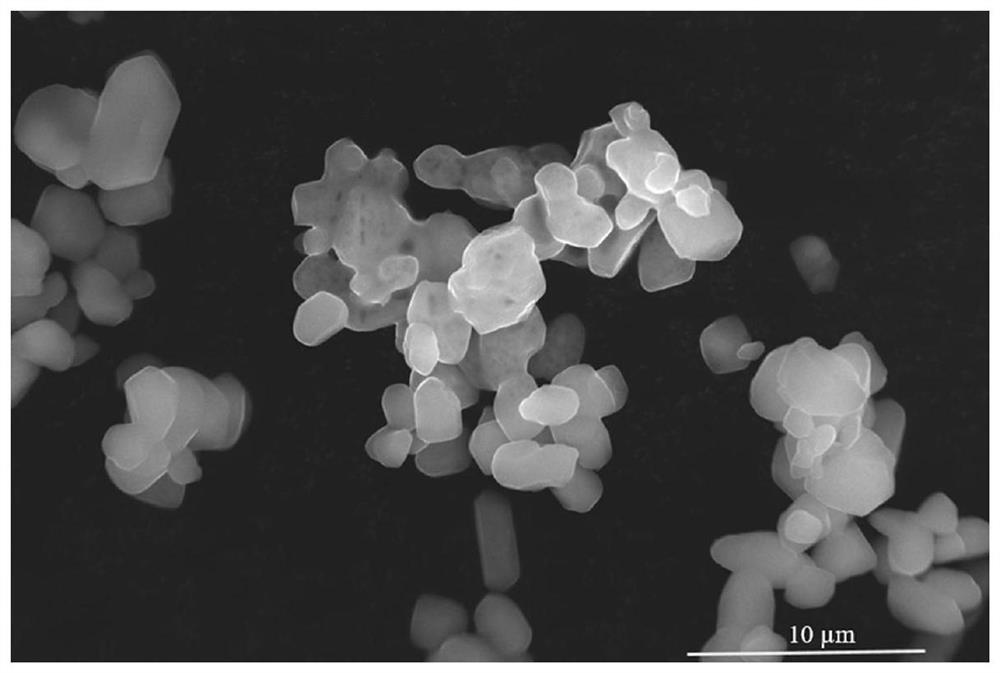

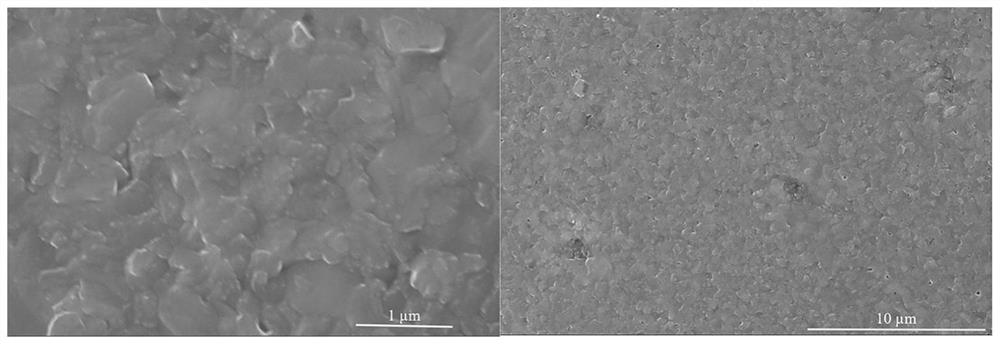

[0032] Embodiment 1 utilizes the inorganic CsPbI prepared by gained DMAI powder 3 The scanning electron microscope image of the perovskite thin film is shown in figure 2 shown.

Embodiment 2

[0034] a. Add 40ml of hydroiodic acid solution to 20ml of N,N-dimethylformamide solution to form a mixed solution, stir at low temperature for 4h, and mark it as solution A.

[0035] b. Rotate solution A in a water bath at 90°C for 3.5 hours, until it becomes viscous;

[0036] c. Dissolve the viscous substance in 60ml of ethanol to form a clear solution B;

[0037] d. Add 300ml of diethyl ether into solution B, extract the precipitate, and mark it as C precipitate;

[0038] e. heat-treat the C precipitate prepared above in an oven at 40° C. for more than 4 hours to obtain DMAI powder with high crystallinity.

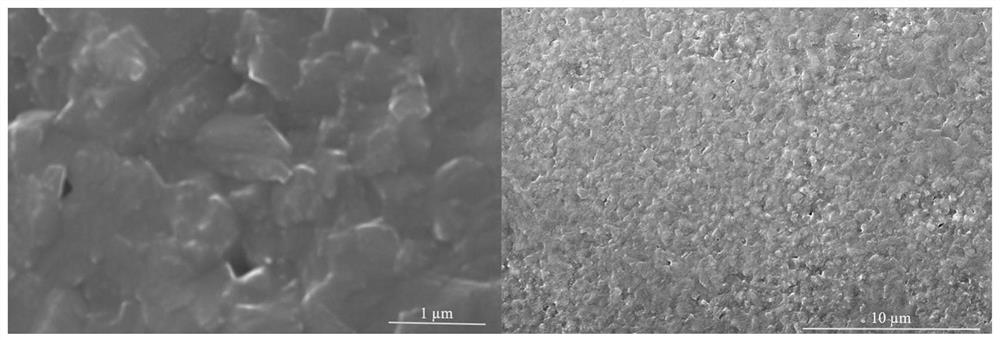

[0039] Embodiment 2 utilizes the inorganic CsPbI prepared by gained DMAI powder 3 The scanning electron microscope image of the perovskite thin film is shown in image 3 shown.

Embodiment 3

[0041] a. Add 60ml of hydroiodic acid solution to 20ml of N,N-dimethylformamide solution to form a mixed solution, stir at low temperature for 4h, and mark it as solution A.

[0042] b. Rotate solution A in a water bath at 90°C for 4 hours, until it becomes viscous;

[0043] c. Dissolve the viscous substance in 70ml of ethanol to form a clear solution B;

[0044] d. Add 350ml of diethyl ether into solution B, extract the precipitate, and mark it as C precipitate;

[0045] e. heat-treat the C precipitate prepared above in an oven at 40° C. for more than 4 hours to obtain DMAI powder with high crystallinity.

[0046] The obtained DMAI powder of embodiment 3 prepares inorganic CsPbI 3 The scanning electron microscope image of the perovskite thin film is shown in Figure 4 As shown, the grain size is more obvious, and the film is denser and smoother.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com