Preparation method of self-assembly polymer material with visible light and pH responsiveness

A responsive, visible light technology, applied in the field of polymer materials, can solve the problems of harmful organisms, short wavelength of ultraviolet light, strong destructive power, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

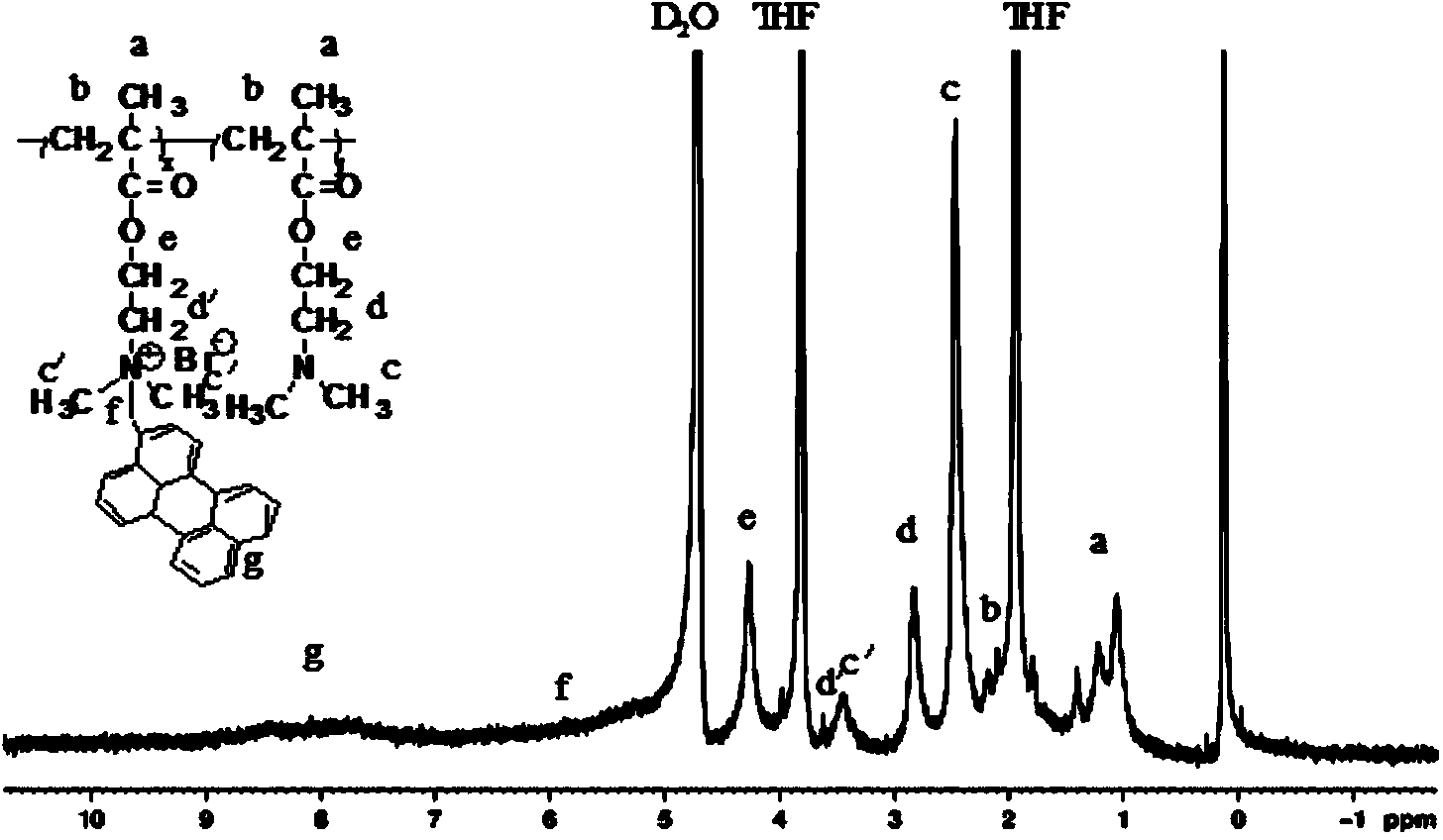

[0024] Add 225 mg of polydimethylaminoethyl methacrylate to a 25 ml round bottom flask, add 4 ml of solvent tetrahydrofuran, add 50 mg of perylene bromide, react at 70 degrees Celsius for 24 hours, and precipitate the resulting product in n-hexane for two time, in a vacuum oven with 55 degrees centigrade drying for 24 hours, finally obtained 200 mg of product, the proton nuclear magnetic spectrum as figure 1 .

[0025] Its synthetic route is shown in the figure below

[0026]

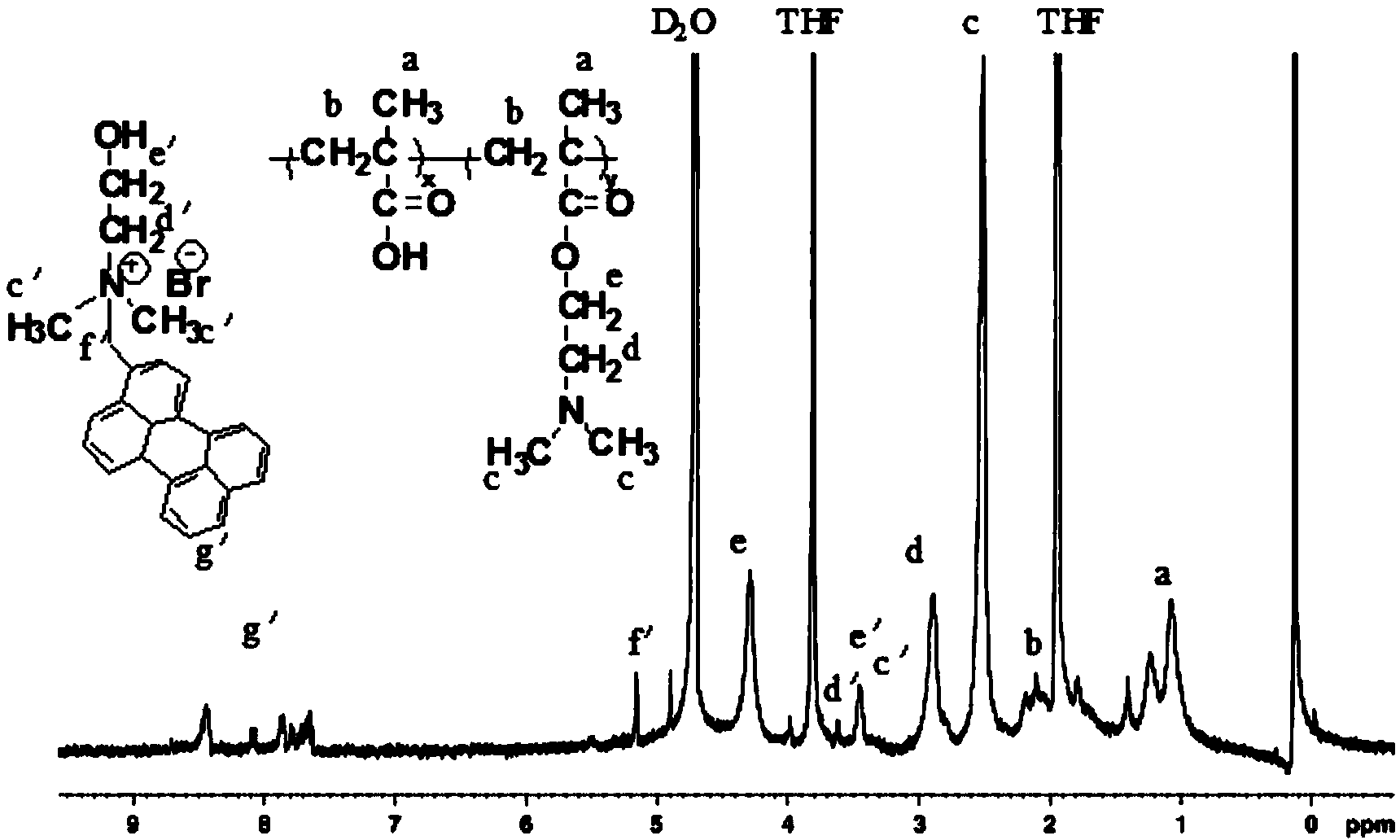

[0027] The synthesized product is photoresponsive, and the H-NMR spectrum after irradiation is as follows: figure 2 .

[0028] The synthesized amphiphilic polymer can self-assemble into micelles in water. Dissolve 9 mg of polydimethylaminoethyl methacrylate grafted with an amphiphilic polymer fluorescent group perylene in 2 ml of tetrahydrofuran, and stir thoroughly with a magnetic stirrer to completely dissolve the polymer in tetrahydrofuran to form a uniform Then add deionized water dropwise t...

example 2

[0031] According to Example 1, amphiphilic polymer perylene-grafted polydimethylaminoethyl methacrylate was prepared. Preparation of micelles loaded with Nile Red molecules: Dissolve 9 mg of polydimethylaminoethyl methacrylate grafted with perylene, an amphiphilic polymer fluorescent group, in 2 ml of THF, and then add 0.9 mg of Nile Red, Fully stir with a magnetic stirrer to completely dissolve the polymer in tetrahydrofuran to form a uniform polymer solution, then add deionized water dropwise to the polymer solution at a rate of 1 to 2 microliters per second, and add 2 ml dropwise, Stir while adding dropwise, and continue stirring for 3 hours after dropwise addition to induce micelle formation. Finally, 16 mL of deionized water was added to fix the formed micelles. The formed micellar solution was volatilized in the air for one week, or dialyzed in deionized water for 2 days to remove tetrahydrofuran in the solution, and then the micellar solution loaded with Nile Red could...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com