Ceramic proppant added with aluminium dihydrogen phosphate and preparation method of ceramic proppant

A technology of aluminum dihydrogen phosphate and proppant, which is applied in chemical instruments and methods, earthwork drilling, drilling composition, etc. The effect of powder removal and crack generation, product quality improvement, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

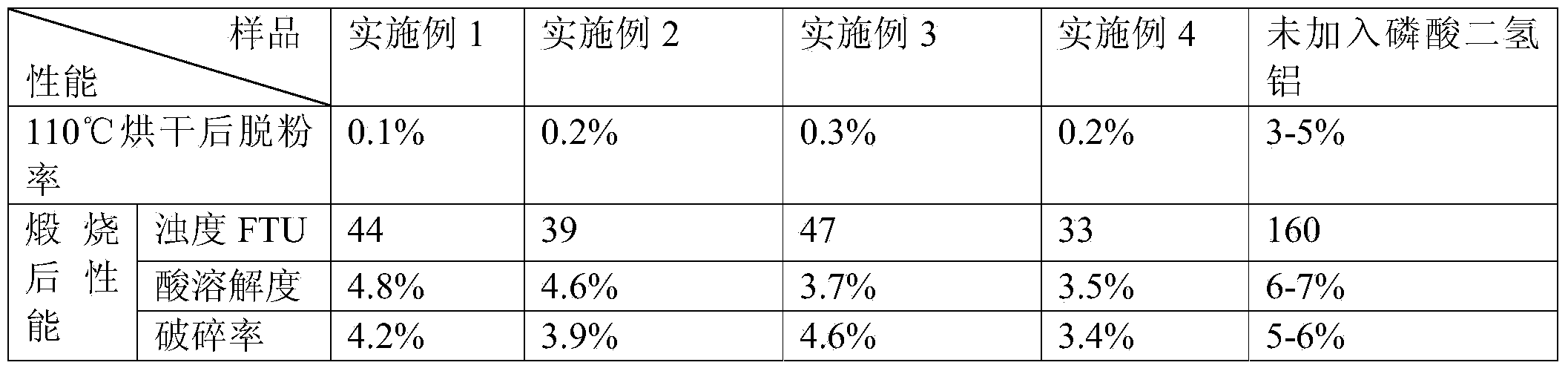

Examples

Embodiment 1

[0021] Prepare 5kg of granulation powder, make aluminum dihydrogen phosphate into a solution with a concentration of 12%, use a disc granulator to granulate, add 1.5kg of granulation powder to the granulator, start the turntable, and the turntable rotates clockwise, keeping the speed at 30rpm Keep the same, make the granulated powder do parabolic motion in the disc granulator; add 2g of the prepared aluminum dihydrogen phosphate aqueous solution into the atomized watering can, and spray evenly on the thrown granulated powder until the granulated powder appears For small particles with clear particle size, add 50g of granulation powder at this time, and continue spraying at the same time, repeat adding every 11 seconds, until the remaining 3.5g of granulation powder is added, and the small particles continue to grow to 0.6-0.9mm, stop adding granulation powder and spraying, the disc granulator continued to rotate for 40 minutes to form ceramsite green balls, and then calcined at...

Embodiment 2

[0023] Prepare 5kg of granulation powder, make aluminum dihydrogen phosphate into a solution with a concentration of 20%, use a disc granulator to granulate, add 1.1kg of granulation powder to the granulator, start the turntable, and the turntable rotates clockwise, keeping the speed at 50rpm Keep the same, make the granulated powder do parabolic motion in the disc granulator; add 0.88g of the prepared aluminum dihydrogen phosphate aqueous solution into the atomized watering can, and spray evenly on the thrown granulated powder until the granulated powder When small particles with clear particle size appear, add 80g of granulation powder at this time, continue spraying at the same time, repeat the addition every 10 seconds, until the remaining 3.9g of granulation powder is added, and the small particles continue to grow to 0.6-0.9mm, stop adding granulation Powder and spray, and the disc granulator continues to rotate for 50 minutes to form ceramsite green balls, and then calci...

Embodiment 3

[0025] Prepare 5kg of granulation powder, make aluminum dihydrogen phosphate into a solution with a concentration of 8%, use a disc granulator to granulate, add 1kg of granulation powder to the granulator, start the turntable, and the turntable rotates clockwise, keeping the speed at 40rpm. Change, make the granulated powder do parabolic motion in the disc granulator; add 1.25g of the prepared aluminum dihydrogen phosphate aqueous solution into the atomized watering pot, and spray evenly on the thrown granulated powder until the granulated powder appears For small particles with clear particle size, add 100g of granulation powder at this time, and continue spraying at the same time, repeat adding every 8 seconds until the remaining 4g of granulation powder is added, and the small particles continue to grow to 0.6-0.9mm, stop adding granulation powder and Spray, and the disc granulator continues to rotate for 30 minutes to form ceramsite green balls, and then calcined at 1400°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com