Special gear lubricating oil composition for high speed train

A technology for gear lubricating oil and high-speed trains, applied in lubricating compositions, petroleum industry, etc., can solve the problem of high-speed scratch resistance, high-temperature detergency, high-temperature stability, energy saving and friction reduction, which cannot meet the lubrication requirements of high-speed train gear transmission systems, etc. problem, to achieve the effects of excellent high-speed scratch resistance, low production cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

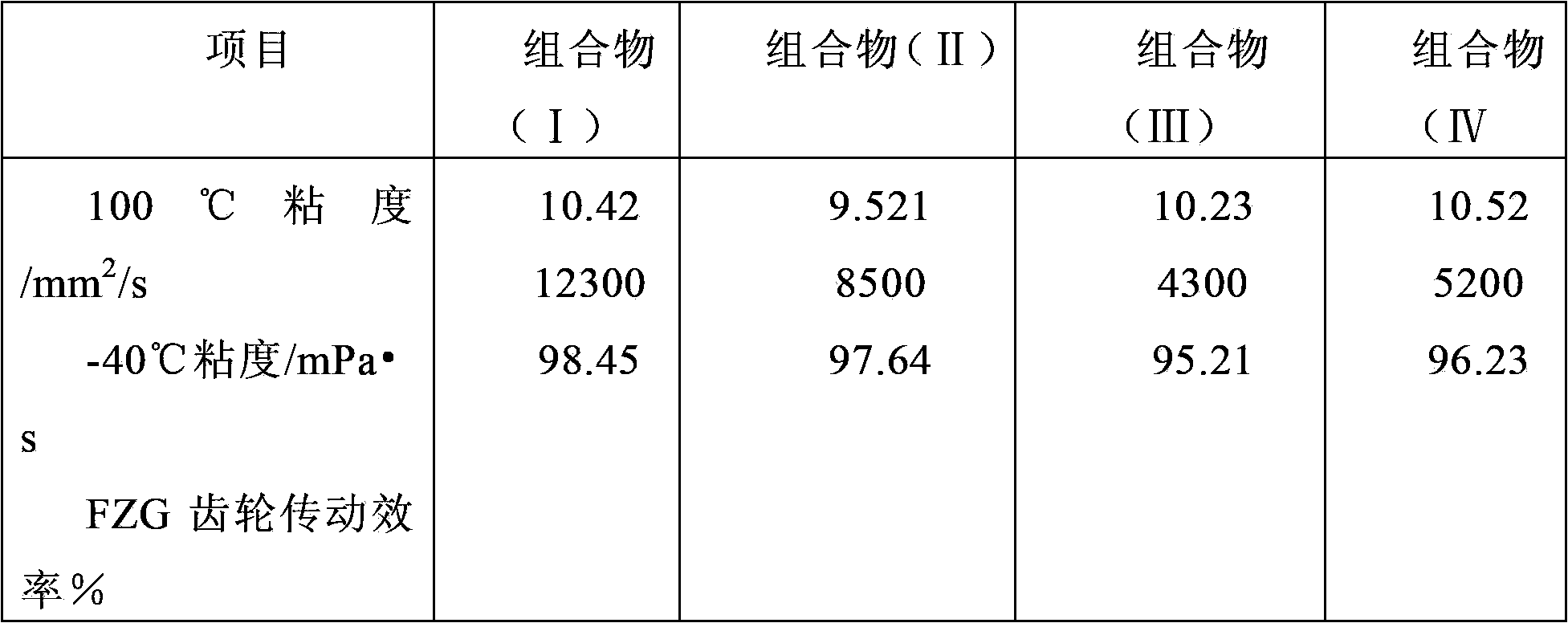

[0022] Lubricating oil composition (I), it comprises: 84.8wt% hydroisomerization dewaxed type III base oil No. 4 oil (component A); 14.0wt% polymethacrylate (component B) of molecular weight 800 ); 1.5wt% polya-olefin (component C); 6.0wt% RHY4208GL-5 vehicle gear oil compounding agent (component D); 1.0wt% acidic lauryl phosphite (component E) ; 0.2 wt% thiadiazole n-octyl mercaptan formaldehyde condensate (component F); 2.0 wt% polyisobutenyl succinimide (component G); 0.5 wt% ethylene glycol oleate (Component H). Lubricating oil composition (II) is the same except that 84.8wt% of hydroisomerization dewaxed Group III base oil No. 4 oil in component (A) is replaced by 84.8wt% poly-olefin synthetic oil PAO-4 Composition (I). Lubricating oil composition (Ⅲ) is the same as composition (I) except that 84.8wt% hydroisomerized dewaxed Group III base oil No. 4 oil of component (A) is replaced by 84.8wt% diester synthetic oil. Lubricating oil composition (Ⅳ) is the same as composi...

Embodiment 2

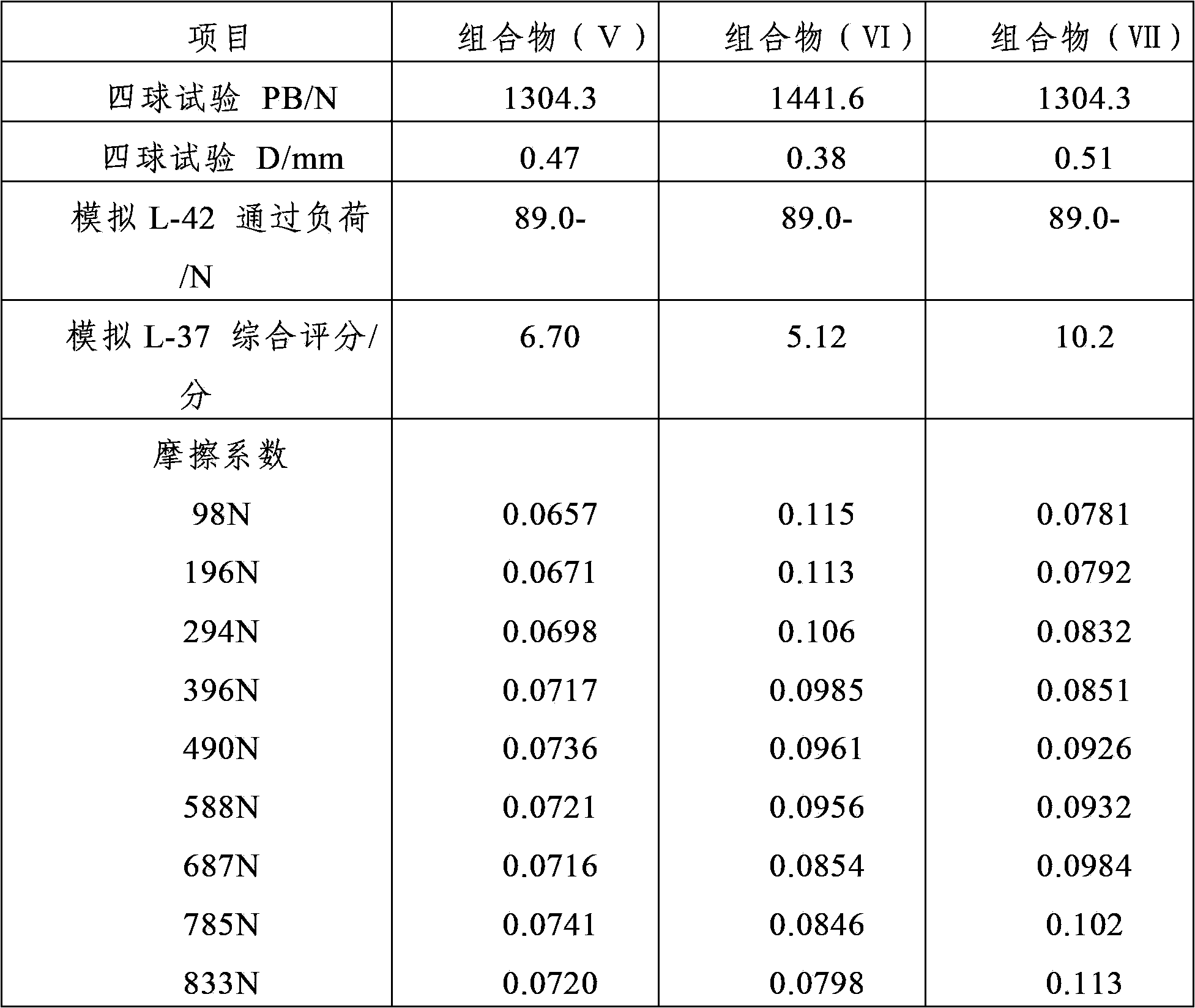

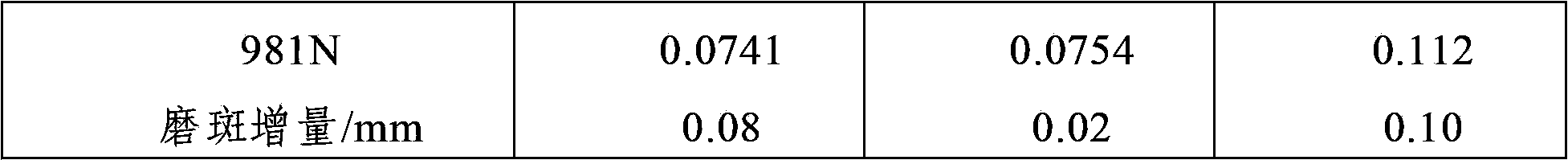

[0027] Lubricating oil composition (Ⅴ), it comprises: the polyalkene synthetic oil PAO-4 of wt%, the diester synthetic oil (component A) of wt%; The polymethacrylate of the molecular weight 800 of 20.0wt% ( Component B); 0.1wt% poly-olefin (component C); 5.0wt% RHY4208A GL-5 vehicle gear oil compound (component D); 0.5wt% acidic lauryl phosphite ( Component E); 0.05 wt% of thiadiazole n-octylamine formaldehyde condensate, 0.05 wt% of n-octyl thiadiazole (component F); 5.0 wt% of borophosphorylated polyisobutenyl succinimide (Component G); 0.3% by weight molybdenum di-n-octyldithiocarbamate (Component H). Lubricating oil composition (VI) is the same as composition (V) except that 0.5 wt% of acidic lauryl phosphite in component (E) is replaced by 0.5 wt% of dodecyl phosphonate. Lubricating oil composition (VII) is the same as composition (V) except that 0.5 wt% of acidic lauryl phosphite in component (E) is replaced by 0.5 wt% of dodecyl phosphate. The test results of composit...

Embodiment 3

[0033] Additive composition (Ⅻ), it includes: 55.6wt% poly-alkene synthetic oil PAO4, 14.4wt% ester synthetic oil diester (component A); 20.0wt% polymethacrylate (component B); 0.1wt% polya-olefin (component C); 3.8wt% RHY4208A API GL-5 vehicle gear oil compound (component D); 0.5wt% dodecyl phosphite, 0.5wt % of dodecyl phosphonate (component E); 0.1wt% of thiadiazole octadecylamine formaldehyde condensate (component F); 2.0wt% of boron phosphated polyisobutenyl succinimide ( Component G); 0.5wt% borated glycerol oleate, 0.25wt% molybdenum di-n-butyldithiocarbamate, 0.25wt% organic molybdenum amine compound (component H). The evaluation results of composition (XII) are listed in Table 3.

[0034] Table 3 Composition (XII) evaluation results

[0035]

[0036]

[0037] The experimental results show that the lubricating oil composition (Ⅻ) has not only passed the L-42, L-37, L-33, L-60, L-60-1 gear bench and FZG gear machine test, but also has the same test as the commer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com