Method for producing cellulase through fermentation by adopting corn cob as main raw material

A technology of cellulase and main raw materials, which is applied in the field of fermenting cellulase with corn cob as the main raw material, can solve the problem of high cost, and achieve the effects of low cost, low price and significant economic benefit prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

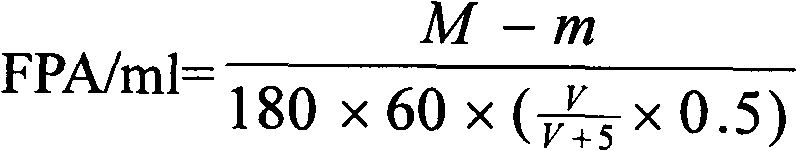

Image

Examples

Embodiment 1

[0043] On a sterile ultra-clean bench, take a slant strain, add 10 ml of 0.9% physiological saline, scrape off the spores on the culture medium with a bamboo stick, and obtain the strain spore liquid. Get 1ml bacterial seed spore liquid and put into the 250ml triangle that contains 50ml seed culture medium, place shaker. Culture conditions: rotation speed 200rpm, temperature 28°C, constant temperature cultivation for 50 hours, which is the seed liquid for fermentation and enzyme production.

[0044] Corncobs are prepared into corncob powder through pulverization, according to corncob 20g / L, corn steep liquor 12g / L, (NH4) 2 SO 4 1.2g / L,KH 2 PO 4 2g / L, MgSO 4 7H 2 O0.2g / L, CaCl 2 Mix 5 liters of enzyme-producing medium at a ratio of 0.2g / L, adjust the pH to 5.0 with phosphate, put it into a 7-liter fermenter, add 2ml of antifoaming agent, and sterilize at 121°C for 30 minutes.

[0045] The cultivated seeds are inoculated into a 7-liter fermenter equipped with 5 liters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com