Atomized water cooling device of sintered ore

A cooling device and atomized water technology are applied in the field of devices for cooling hot sintered ore with air and atomized water in metallurgical enterprises. , the device maintenance is small, the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

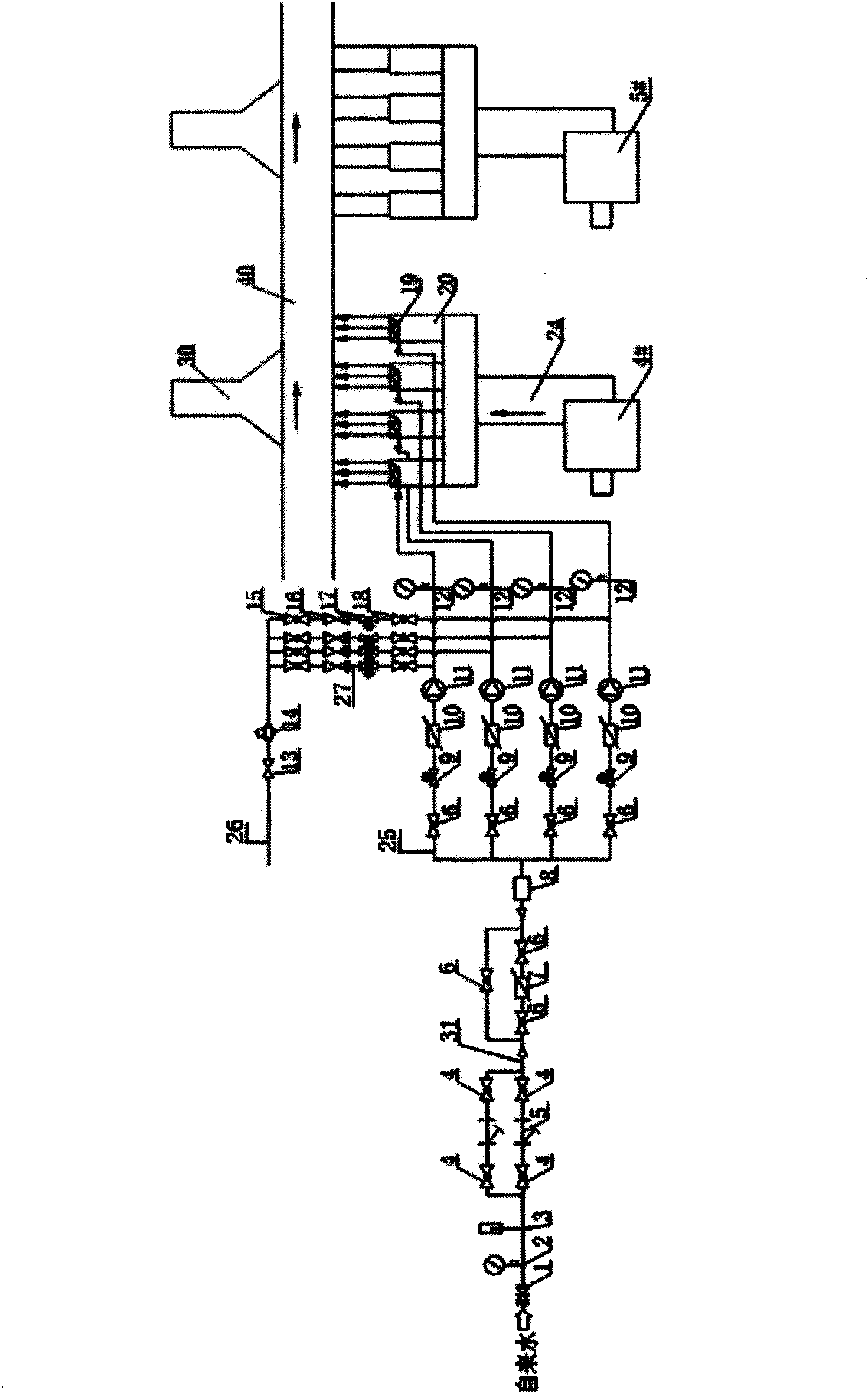

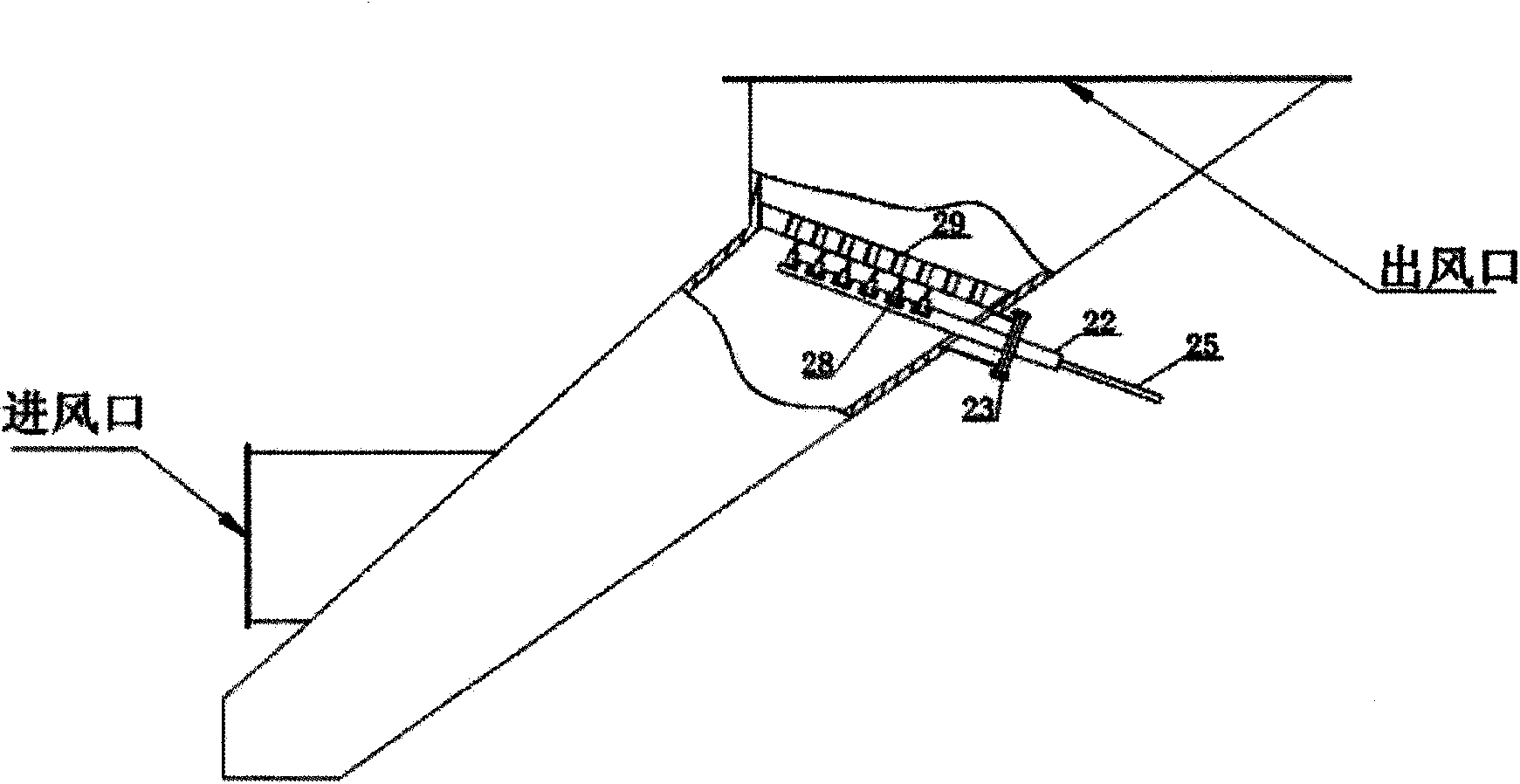

[0030] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] As shown in the figure: the cooling device of the sintering machine has five blowers placed in sequence. Because the first three can produce higher temperature flue gas, the waste heat is recycled through the flue gas waste heat boiler and the condensing steam turbine generator. There is no need to install an atomized water cooling device. After a sintered ore atomized water cooling device is installed on the fourth blower, the fifth blower can be stopped.

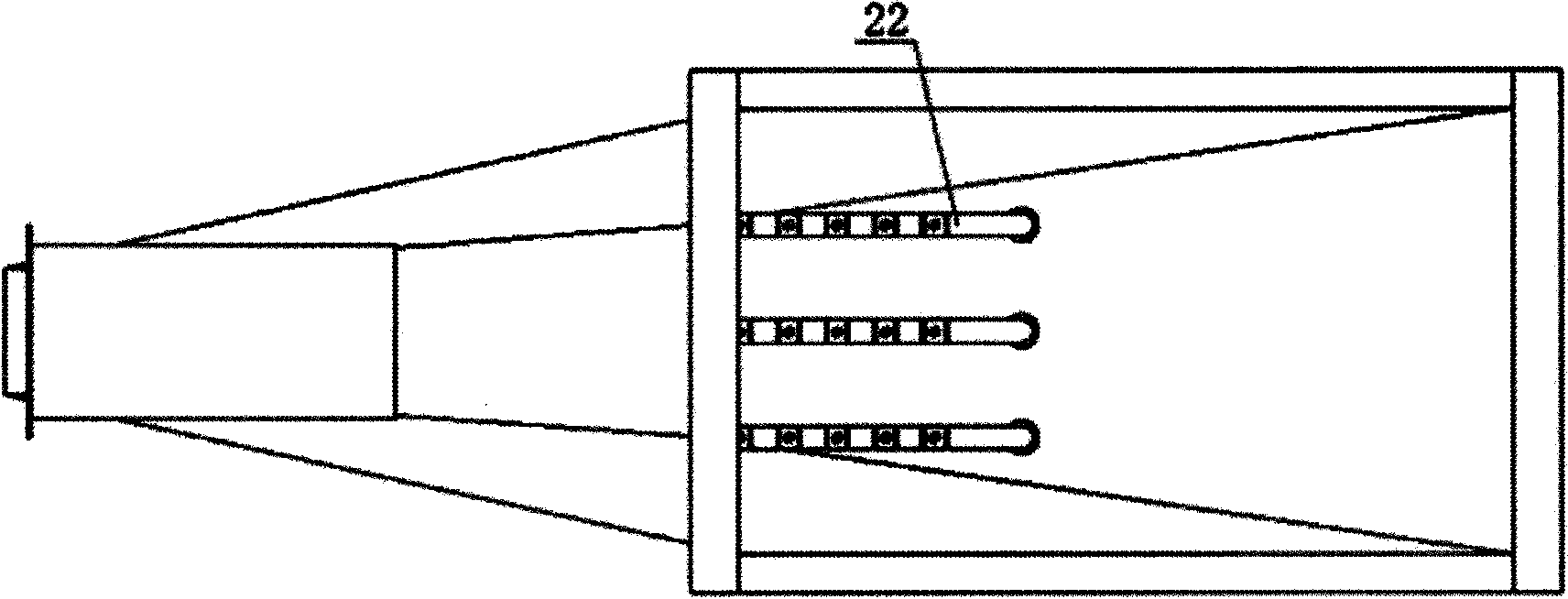

[0032] A cooling device for a sintering machine includes a grate plate 40, a blower, an air pipe 24, an air pipe branch 20, and a chimney 30. One end of the air pipe 24 is connected with the blower, and the other end of the air pipe 24 is provided with 4 air pipe branches 20 in parallel. The air duct branch 20 is located below the grate 40, the air outlet of the duct branch 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com