Closed electro-hydraulic actuator and assembly of closed electro-hydraulic actuator

An electro-hydraulic actuator, closed-type technology, applied in the direction of machines/engines, fluid pressure actuators, engine components, etc., can solve problems such as difficult arrangement, strict requirements, and complexity, so as to increase the spring loading function and avoid external leakage Leakage, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

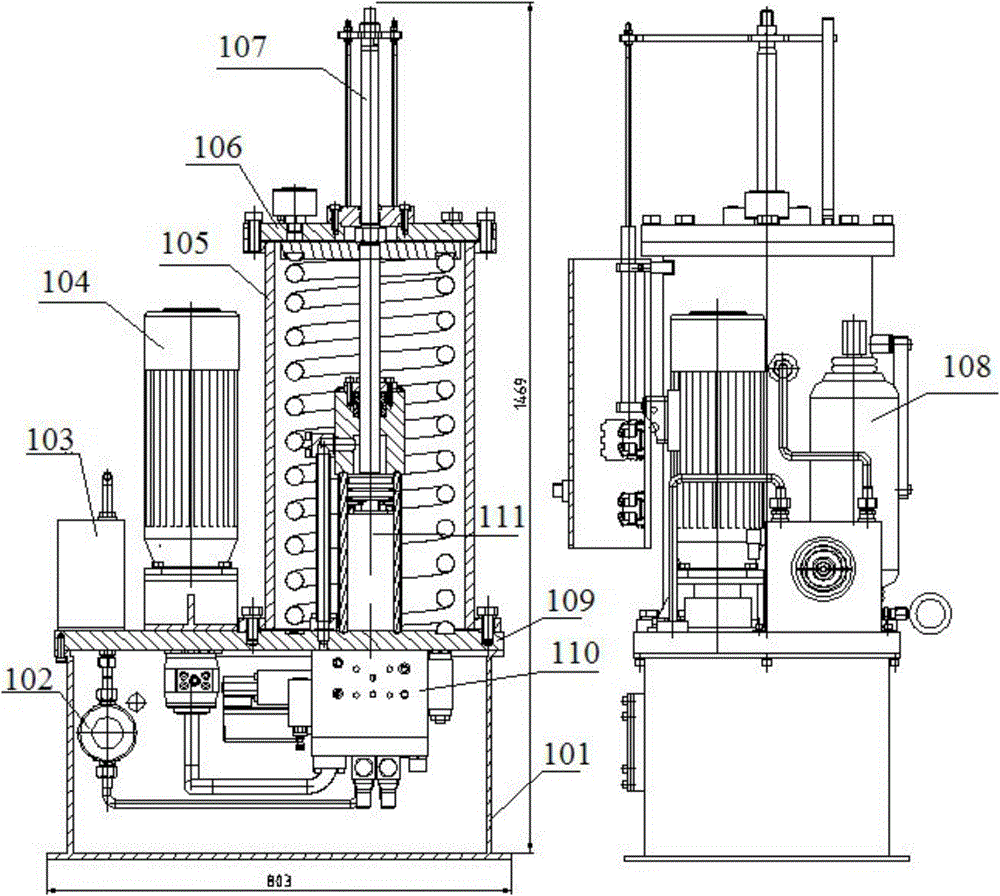

[0053] Please also see Figure 2 to Figure 3 .

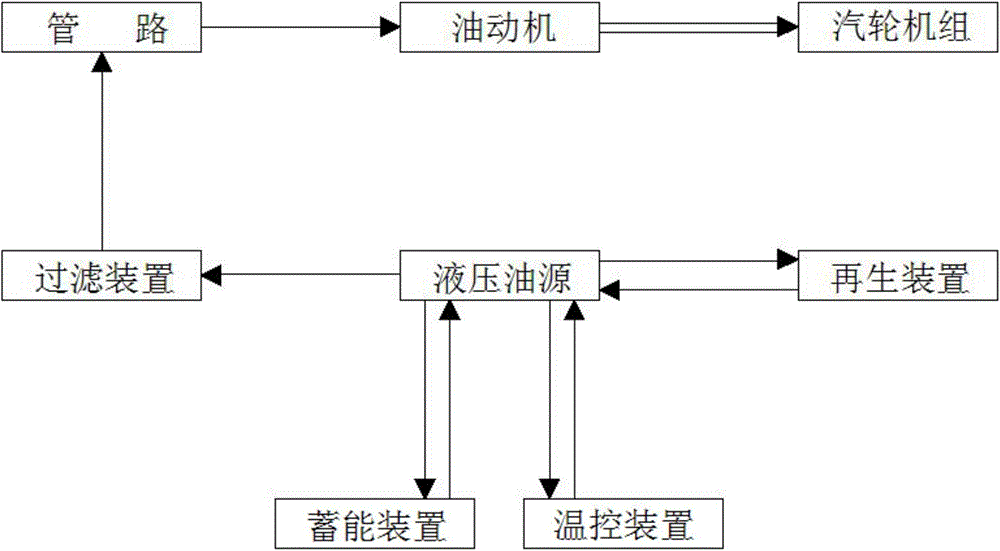

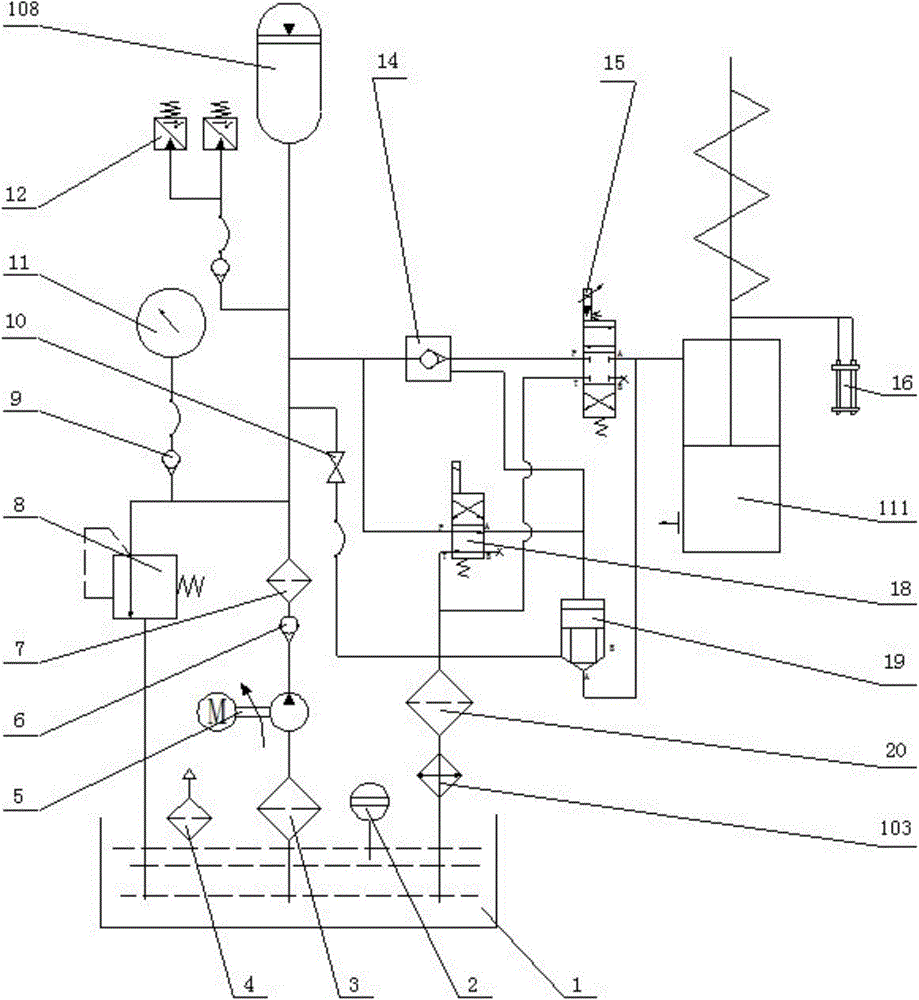

[0054] This embodiment provides a closed electro-hydraulic actuator, including: an oil tank, an oil motor, a filter mechanism, an energy storage mechanism, a cooler, an oil cylinder casing, a spring mechanism, and a motor pump set, and the oil motor includes an oil cylinder and an integrated module , the oil cylinder, energy storage mechanism and cooler of the oil motor are all installed on the top cover of the oil tank and communicate with the oil tank through an integrated module or pipeline, and the filter mechanism is respectively connected with the oil motor, energy storage mechanism and The cooler is connected, and the motor pump unit is connected with the oil tank; wherein:

[0055] The oil cylinder is installed on the upper side of the oil tank top cover, and is set in the center of the inner cavity of the oil tank shell, and the integrated module is installed on the lower side of the oil tank top cover, corresponding t...

Embodiment 2

[0107] This embodiment provides a combined closed-type electro-hydraulic actuator, including a plurality of closed-type electro-hydraulic actuators according to any one of claims 1 to 9, wherein the plurality of closed-type electro-hydraulic actuators are respectively connected with The regulating steam valves of the steam turbine unit are connected in one-to-one correspondence.

[0108] Specifically:

[0109] In this embodiment, a small pump set with a displacement of 5-6 liters and a driving power of 2.5 kw is used to provide hydraulic power of an oil motor. The power unit of the traditional system is: a pump set with a hydraulic oil source displacement of 63 liters and a driving power of 30KW, which provides hydraulic power from 2 to 4 oil motors to control 2 to 4 steam valves, and is also equipped with a set of spare power units. If the closed electro-hydraulic actuator and the traditional hydraulic system are configured according to the four steam valves of the steam tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com