Rotor variable-mass frequency-modulation dynamic vibration absorber of rotating machinery

A technology of dynamic vibration absorber and rotating machinery, which is applied in the direction of rotation vibration suppression, mechanical equipment, vibration suppression adjustment, etc. It can solve the problem that the vibration absorber cannot be adjusted and changed in a wide range of frequencies, and achieves good vibration reduction effect and high reliability. , the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

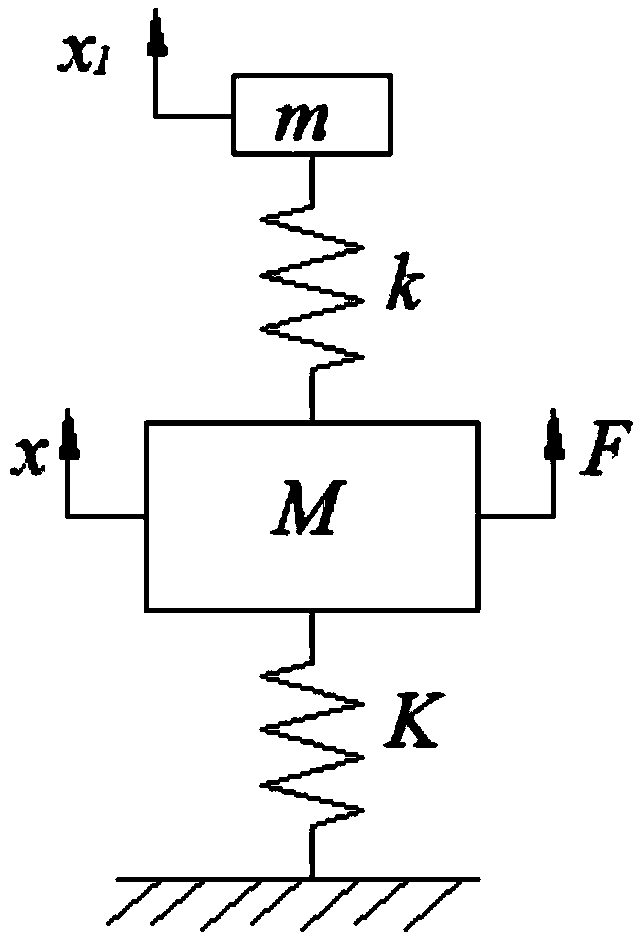

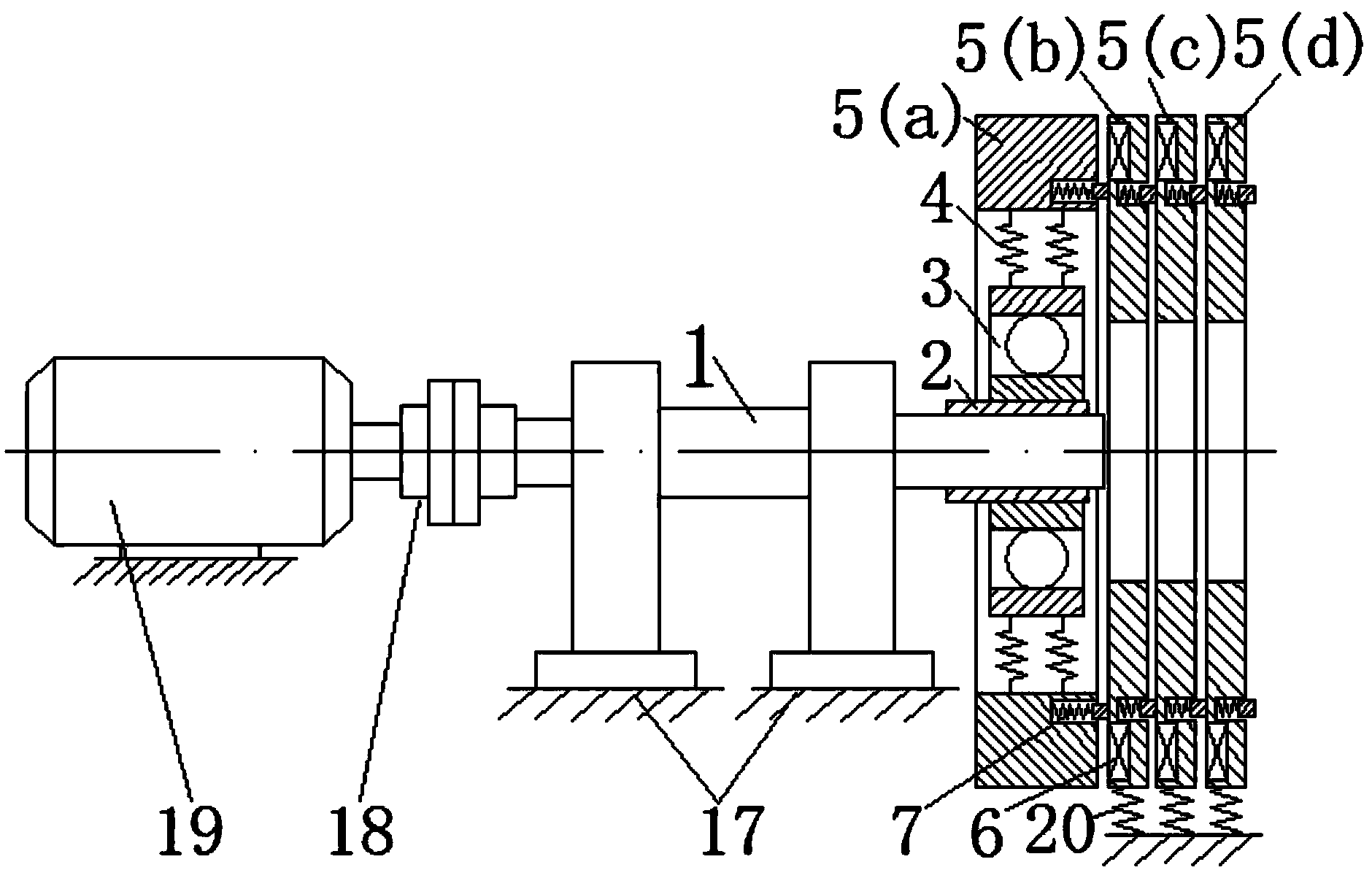

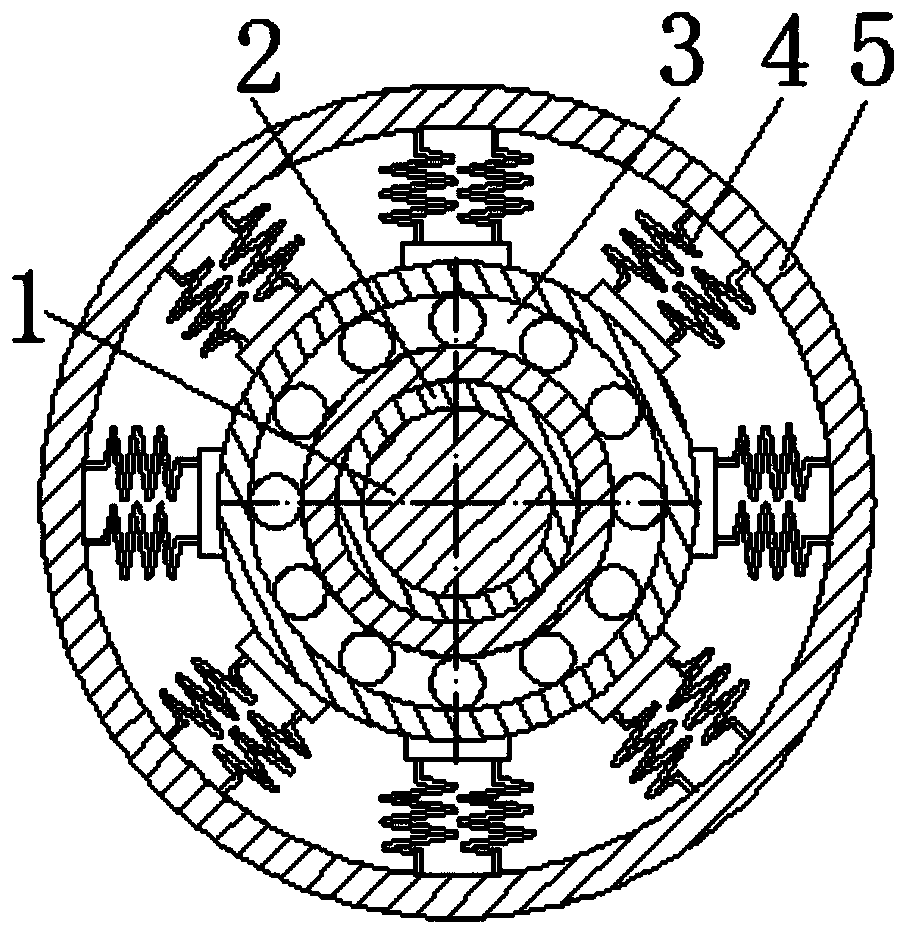

[0032] Such as figure 2 Shown is a schematic structural diagram of the present invention in the rotor system, image 3 It is a structural schematic diagram of the variable mass frequency modulation dynamic vibration absorber of the present invention, Figure 4It is a schematic diagram of the control system of the variable mass frequency modulation dynamic vibration absorber of the present invention, the vibration absorber includes a rotating shaft 1, a shaft sleeve 2, a rolling bearing 3, a spring set 4, annular mass disks 5a, 5b, 5c, 5d, an adsorption device 6, and a release device 7 , relay switch 8, laser velocimeter 9, eddy current displacement sensor 10, vibration signal 11, terminal block 12, signal conditioning module 13, data acquisition card 14, computer 15, control signal 16, rotor system support 17, coupling 18 , motor 19, soft connection 20; the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com