Integral embedded type heat pump dryer

An embedded dryer technology, which is applied to dryers, dryers, household clothes dryers, etc., can solve problems such as inconvenient maintenance, wasteful discharge, and energy waste, and achieve simplified structure, convenient centralized setting, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

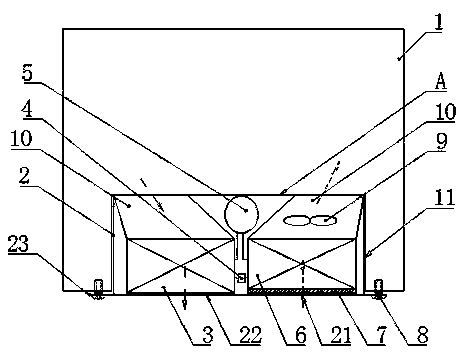

[0014] see figure 1 , the present invention is a whole embedded heat pump dryer, including a conventional heat pump system A and drying chamber 1, heat pump system A includes an evaporator 3 for cooling process air and a condenser as radiator 6 (and a compressor machine 5 and throttle valve 4). The heat pump system A is installed in a casing 2 that guides process air through the drying chamber 1 , and the evaporator 3 and radiator 6 are arranged side by side on the same side (outside) of the casing 2 . An outlet 22 and an inlet 21 for process air are provided at one side of the housing 2 of the evaporator 3 and the radiator 6, respectively. One side of the drying chamber 1 is provided with an installation recess 11 capable of inserting into the casing 2 . When applied to a washing machine, the drying chamber 1 is a drum part of the washing machine. A fan 9 is installed between the radiator 6 and the drying chamber 1 . A filter 7 that can be easily disassembled is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com