Inspection system, charger/discharger, and inspection method of secondary battery

A secondary battery and inspection system technology, applied in the direction of secondary batteries, battery circuit devices, current collectors, etc., can solve the problem of high cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

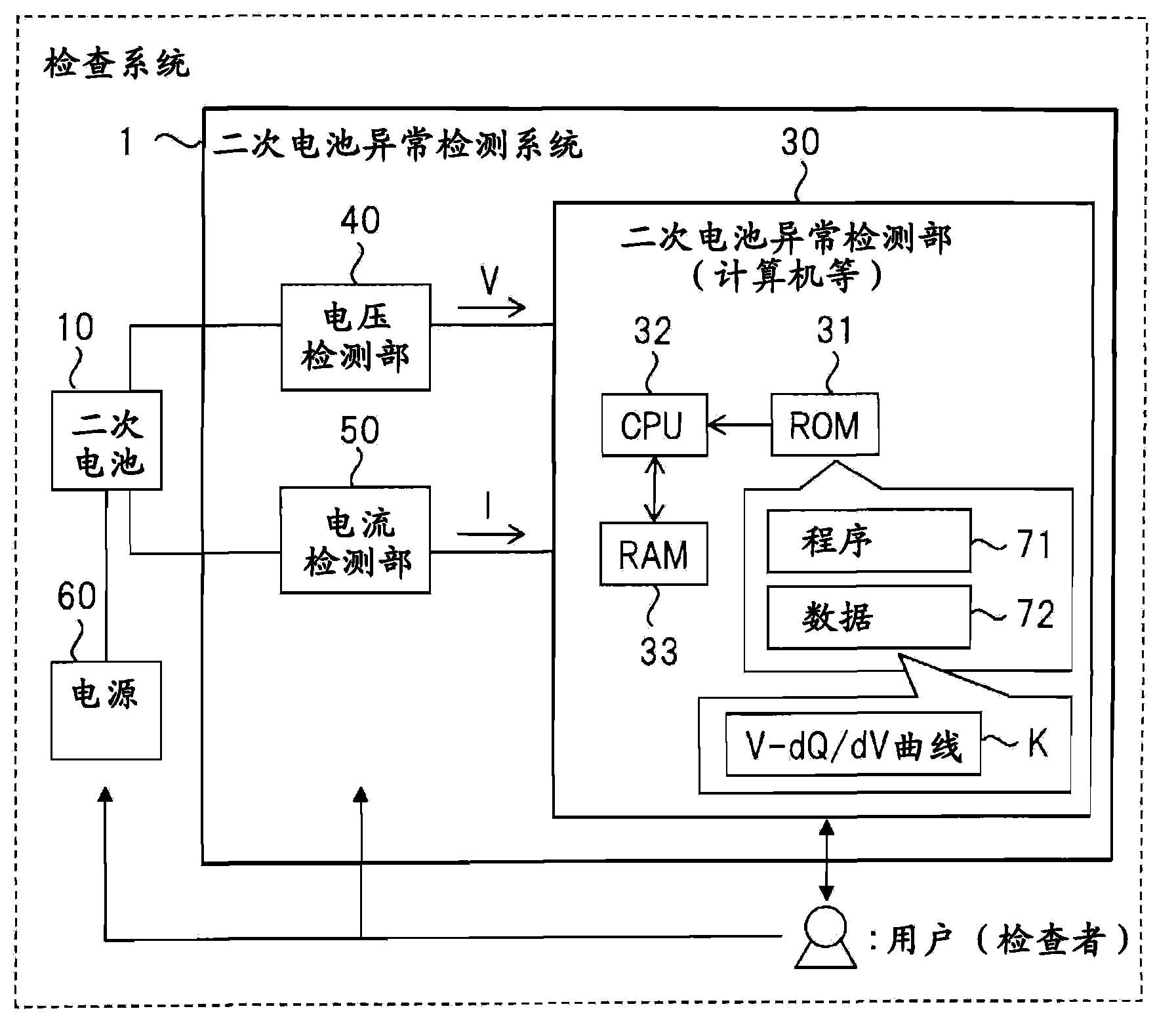

[0048] use figure 1 , Figure 4 to Figure 13 The secondary battery inspection system and the corresponding inspection method according to Embodiment 1 will be described below.

[0049] (system structure)

[0050] figure 1 An overall configuration of the secondary battery inspection system according to Embodiment 1 is shown. This inspection system is configured by connecting an abnormality detection system (secondary battery abnormality detection system) 1 , a secondary battery 10 , and a power supply 60 . The abnormality detection system 1 has a configuration including a voltage detection unit 40 , a current detection unit 50 , and an abnormality detection unit (secondary battery abnormality detection unit) 30 . The secondary battery 10 is a lithium ion secondary battery to be inspected. During the inspection, the secondary battery 10 to be inspected is connected to the voltage detection unit 40 , the current detection unit 50 , and the power source 60 . The voltage dete...

Embodiment approach 2

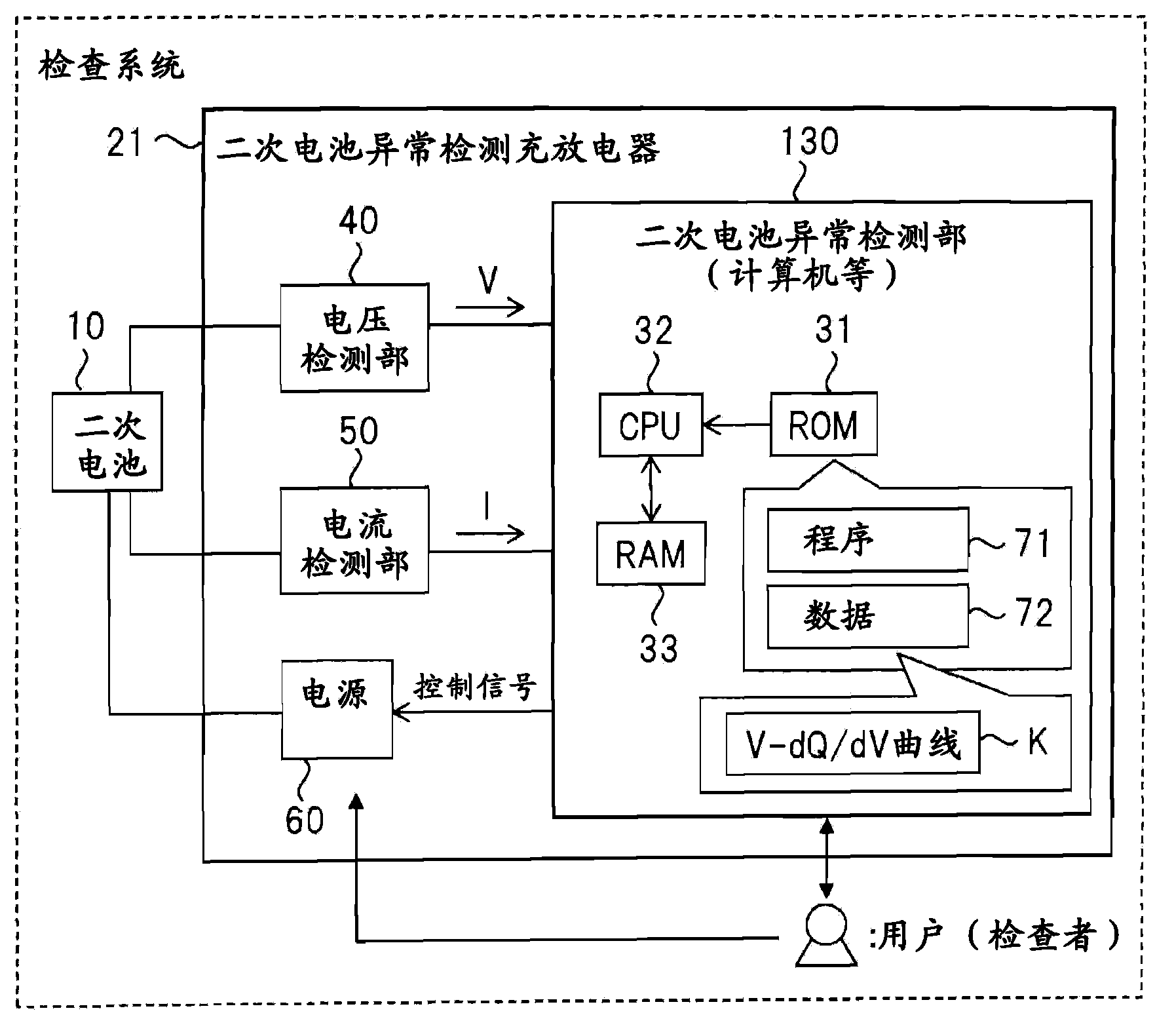

[0062] As the inspection system of Embodiment 2, figure 2 A configuration example of the charge / discharge device 21 (secondary battery abnormality detection charge / discharge device) provided with a secondary battery abnormality detection function is shown. Charger / discharger 21 has the same abnormality detection function of secondary battery 10 as in Embodiment 1 (voltage detection unit 40 , current detection unit 50 , abnormality detection unit 130 , etc.). Furthermore, the charge / discharge device 21 incorporates the power source 60 capable of charging and discharging the secondary battery 10 , and is capable of controlling the power source 60 from the abnormality detection unit 130 (control of the charging and discharging operation). The secondary battery 10 is connected to each part ( 40 , 50 , 60 ) in the same manner as above.

[0063] Like the abnormality detection unit 30 of the first embodiment, the abnormality detection unit 130 of the second embodiment is realized b...

Embodiment approach 3

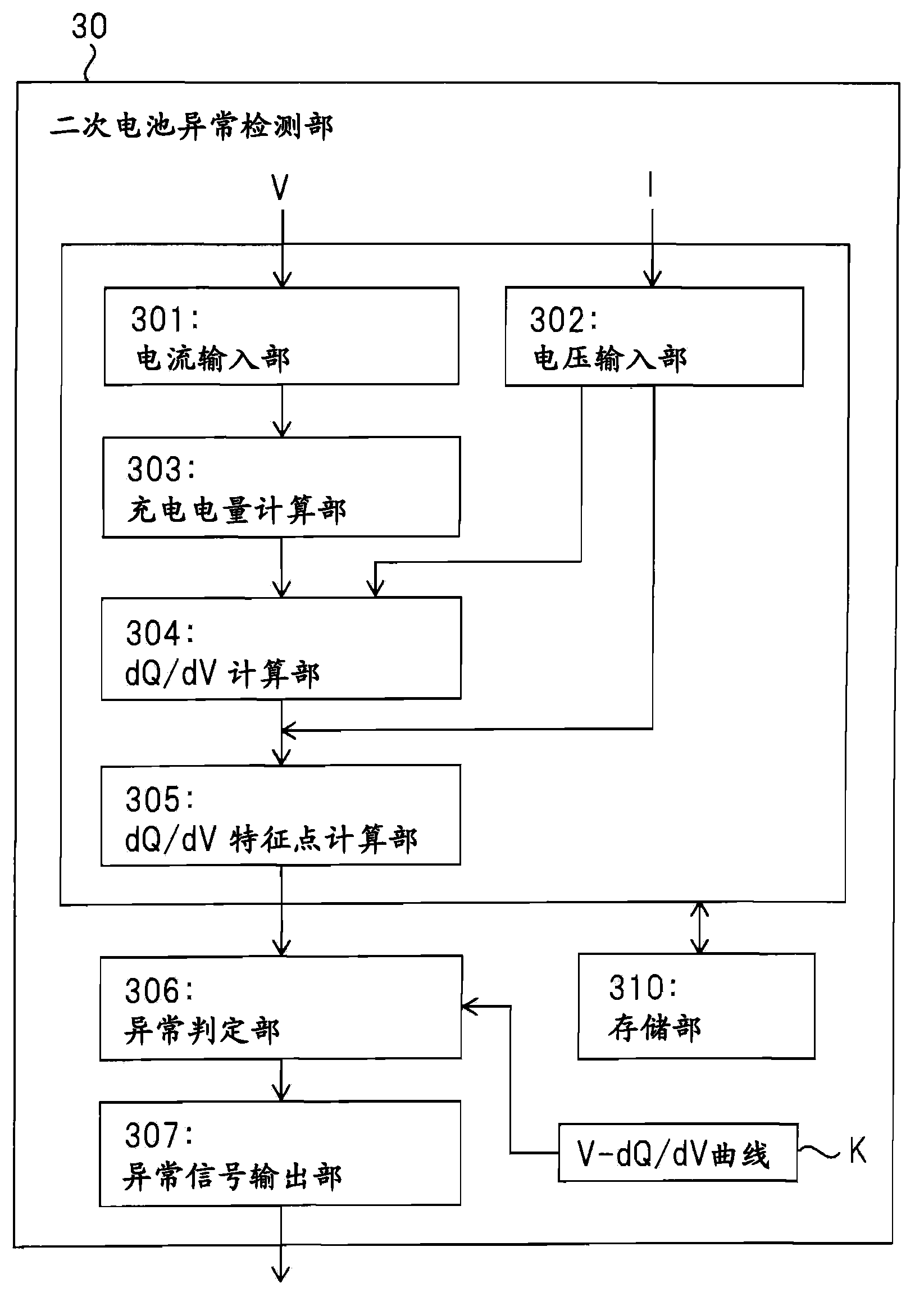

[0065] As the inspection system of Embodiment 3, image 3 A detailed configuration example (functional block configuration) of the abnormality detection unit 30 is shown. The abnormality detection unit 30 has a current input unit 301, a voltage input unit 302, a charging electric quantity calculation unit 303, a dQ / dV calculation unit 304, a dQ / dV characteristic point calculation unit 305, an abnormality determination unit 306, an abnormality signal output unit 307, a memory Section 310 et al. Each of these components may be configured as a program module, or may be configured by a circuit unit or the like. In addition, data information processed by each unit ( 301 to 305 , etc.) is appropriately stored in the storage unit 310 . The following is an outline of processing by the abnormality detection unit 30 .

[0066] The abnormality detection unit 30 receives the voltage V of the secondary battery 10 detected by the voltage detection unit 40 and the current I of the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com