In2O3-ZnO sputtering target

A sputtering target, in2o3 technology, applied in the field of sputtering targets, can solve the problems of not increasing the oxygen partial pressure, a large number of carriers, and easy to generate leakage current, etc., and achieve the effect of suppressing the generation of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

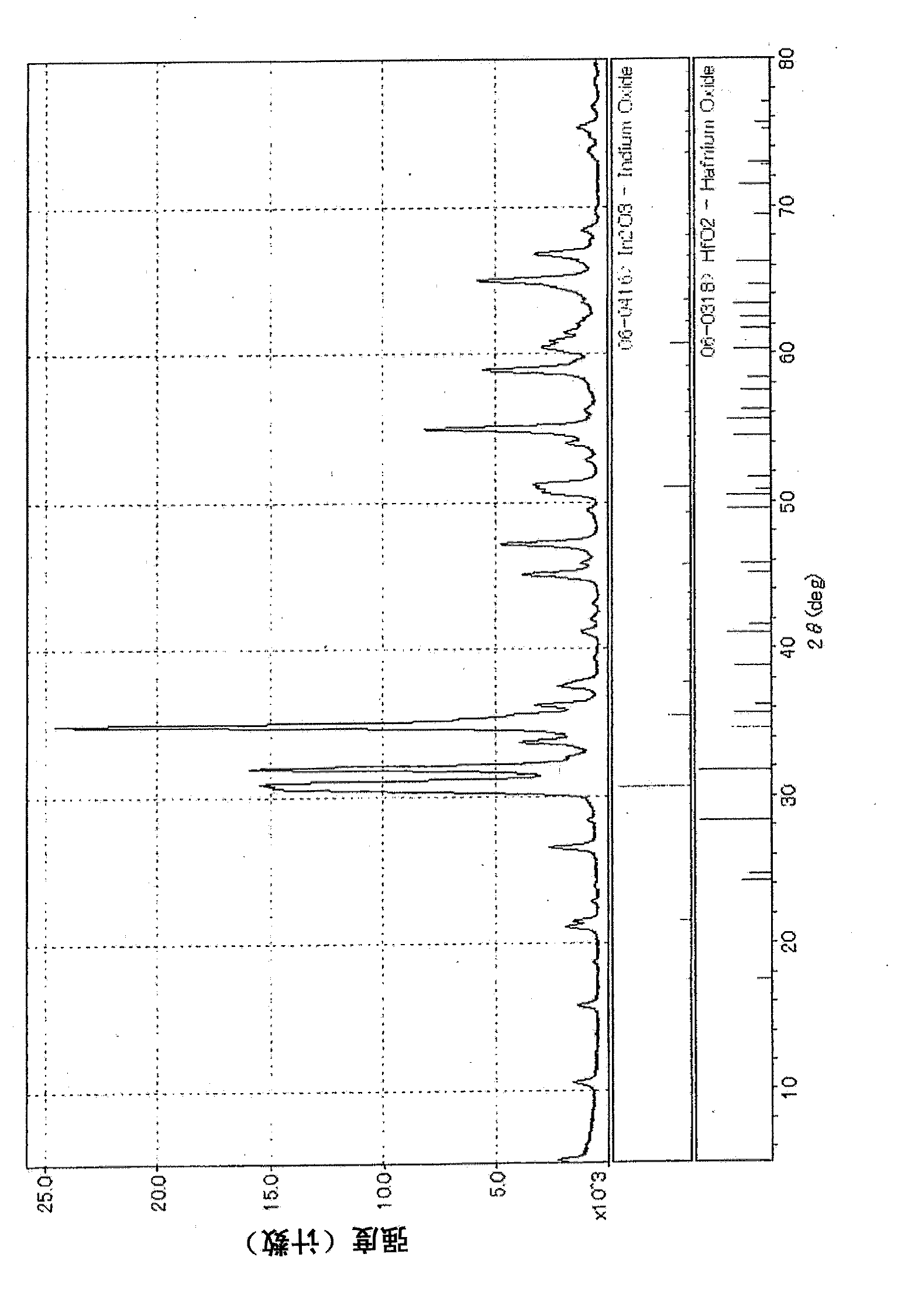

Embodiment 1

[0120] (1) Preparation of raw materials

[0121] As raw materials, indium oxide (manufactured by Asia Material Co., Ltd., average particle size: 1 μm or less, purity: 4N equivalent) and hafnium oxide (manufactured by Wako Pure Chemical Industries, Ltd., average particle size: 1 μm or less, purity: 4N equivalent) were used ). These were mixed so that the atomic ratio [In / (In+Hf)] of the In element to the total of the In element and the Hf element was 0.88. The mixture was supplied to a wet ball mill, mixed and pulverized for 12 hours.

[0122] The resulting mixed slurry was removed, filtered and dried. This dried powder was charged into a firing furnace, and heat-treated at 1000° C. for 5 hours in an air atmosphere.

[0123] Through the above steps, a mixed powder containing In element and Hf element is obtained.

[0124] Zinc oxide (manufactured by High Purity Chemical Co., Ltd., average particle diameter: 1 μm or less, purity: 4N equivalent) was mixed with this mixed powd...

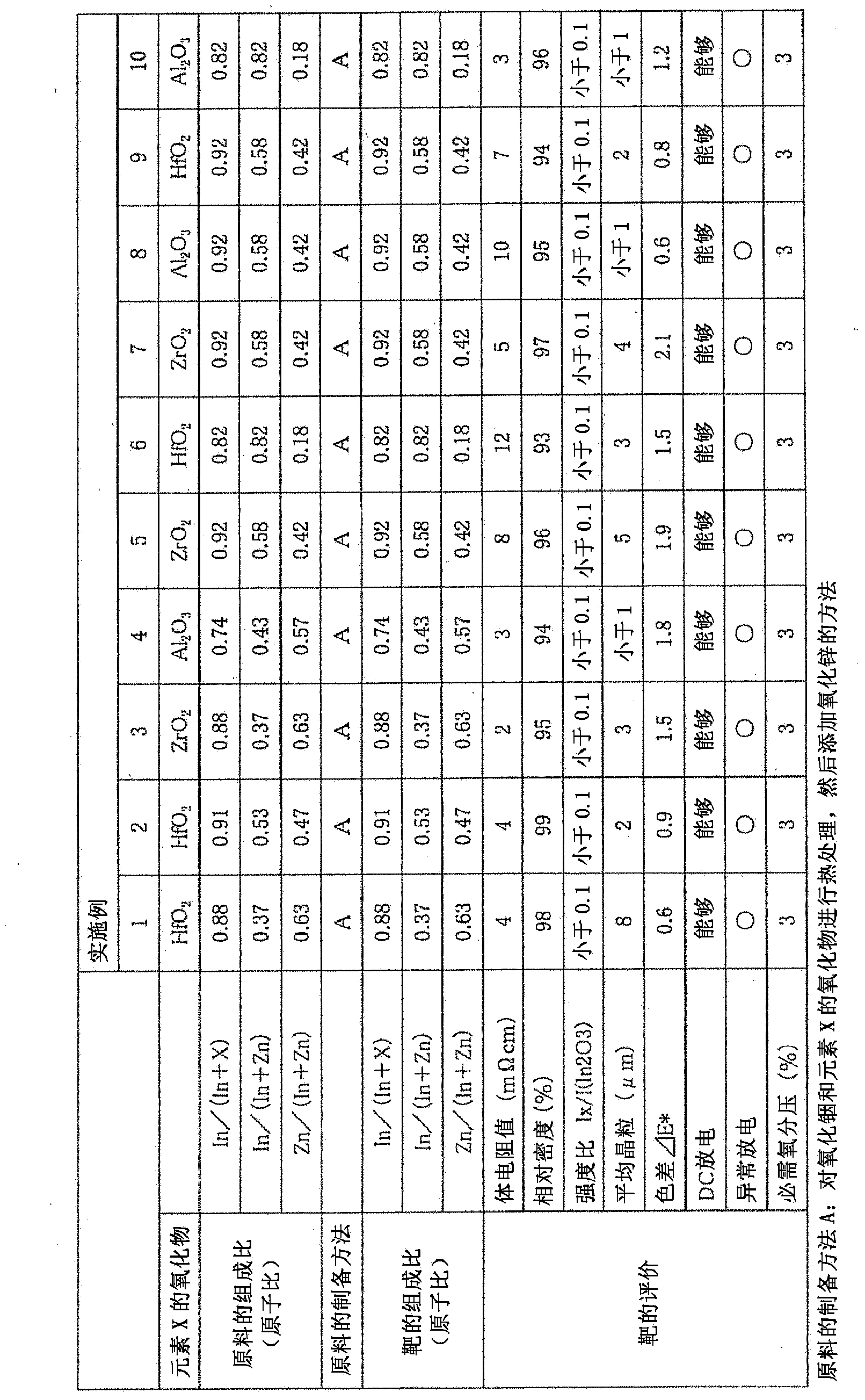

Embodiment 2~25

[0167] In preparation of a raw material, except having changed the compounding ratio of a raw material and the oxide of the element X as shown in Table 1 - Table 3, it carried out similarly to Example 1, and produced and evaluated the sputtering target. The results are shown in Tables 1 to 3.

[0168] It should be noted that the oxides of the element X used were all manufactured by Wako Pure Chemical Industries, Ltd.

Embodiment 26~29

[0170] Indium oxide, zinc oxide, and oxides of element X were weighed in the proportion shown in Table 3, and mixed for 6 hours using a planetary ball mill to obtain a slurry of raw material fine powder. The slurry was filtered, dried and pelletized to prepare a raw material.

[0171] A sputtering target was produced and evaluated in the same manner as in Example 1. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com