Fault diagnosis and feedback system according to third octave flutter of high-speed cold rolling mill

A technology of fault diagnosis and feedback system, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as endangering equipment safety, strip thickness fluctuation, amplitude divergence, etc., to eliminate self-excited vibration, suppress rolling mill Vibration, the effect of improving the life of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

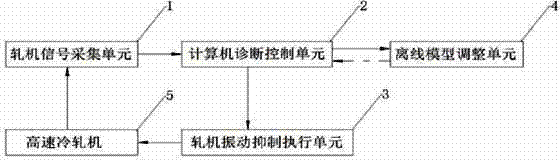

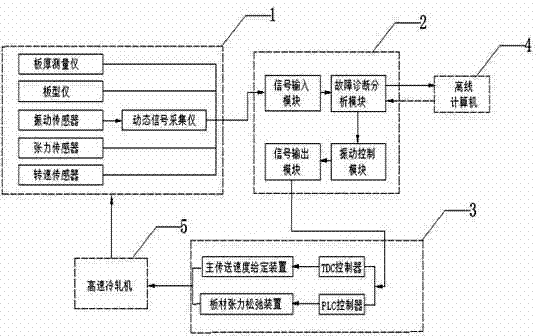

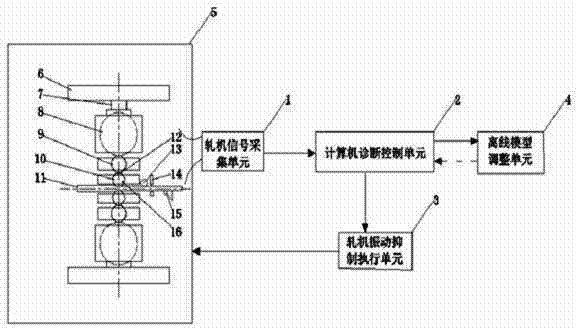

[0030] Such as figure 1 As shown, the present invention provides a fault diagnosis and feedback system for the third octave chatter of high-speed cold rolling mills By The rolling mill signal acquisition unit 1, the computer diagnosis control unit 2, the rolling mill vibration suppression execution unit 3, the off-line model adjustment unit 4 and the high-speed cold rolling mill 5 are composed.

[0031] A rolling mill signal acquisition unit (1), including a plate thickness measuring instrument (14), a plate shape instrument (13), a vibration sensor (12), a dynamic signal acquisition instrument, a tension sensor (15) and a rolling mill speed sensor (16);

[0032] Computer diagnostic control unit (2), including signal input module, fault diagnosis and analysis module, vibration control module and signal output module;

[0033] Rolling mill vibration suppression execution unit (3), composed of TDC controller, PLC controller, sheet tension relaxation device (tension roller) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com