Special numerical control machine tool for milling end face, drilling center hole and lathing outer circle of thin and long shaft part

A technology for drilling center holes and CNC machine tools, which is applied in the field of CNC machine tools, can solve the problems of easy deformation of workpieces, precision, long time consumption, and high scrap rate, and achieve the effects of high time utilization, high machining accuracy, and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail through the drawings and examples below. From these descriptions, the features and advantages of the present invention will become more apparent.

[0061] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

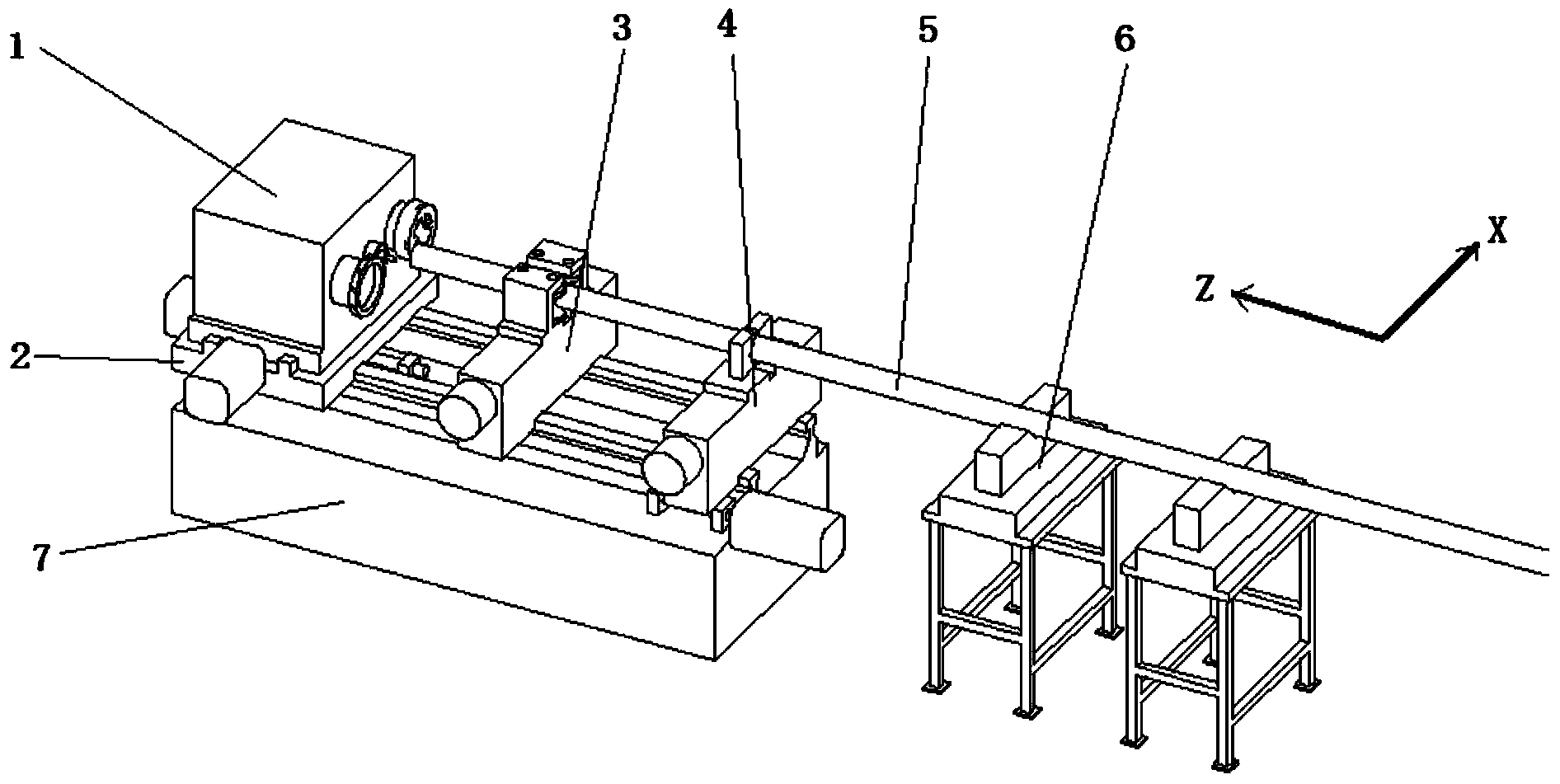

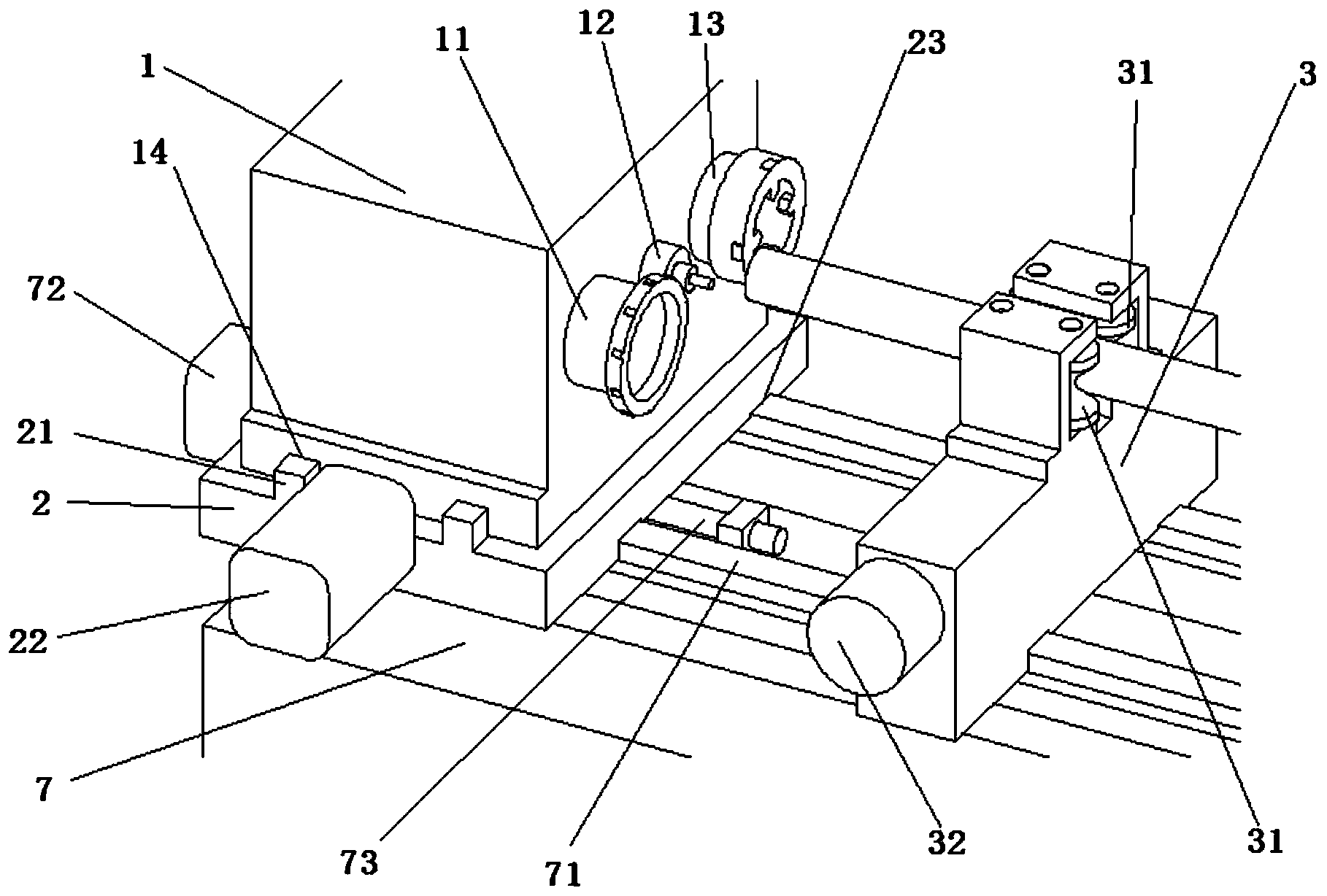

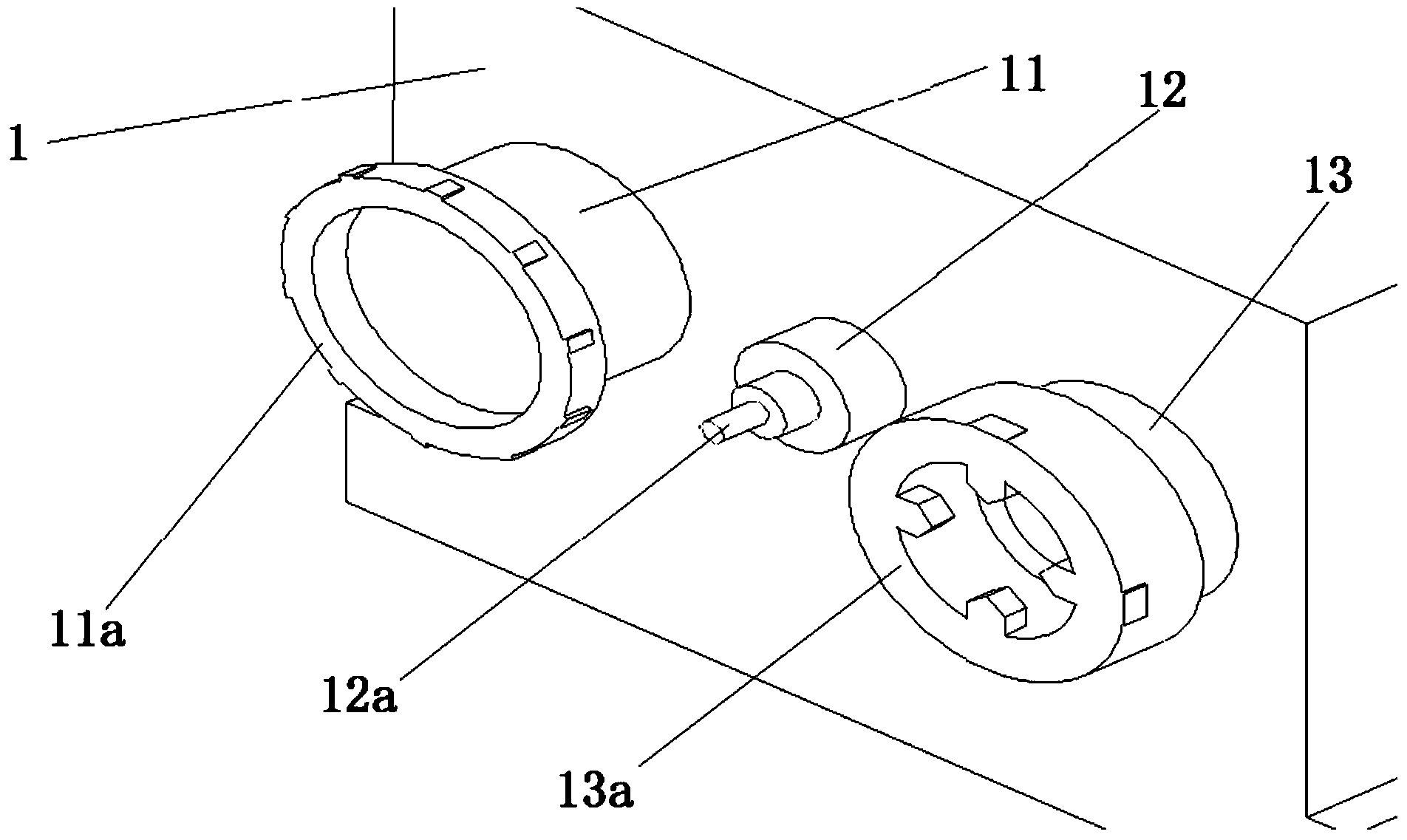

[0062] In a preferred embodiment of the present invention, such asfigure 1 , 2 As shown in and 4, special CNC machine tools for milling end faces, drilling center holes, and turning outer circles of slender shaft parts are provided. The CNC machine tools include:

[0063] The spindle box 1, the spindle box base 2, the clamping and guiding device 3, the clamping and feeding device 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com