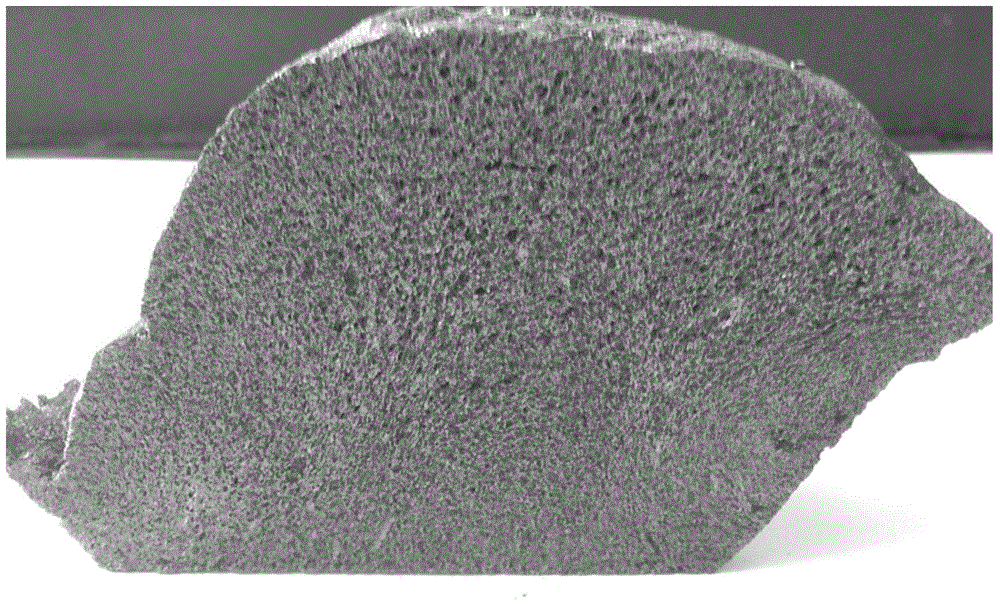

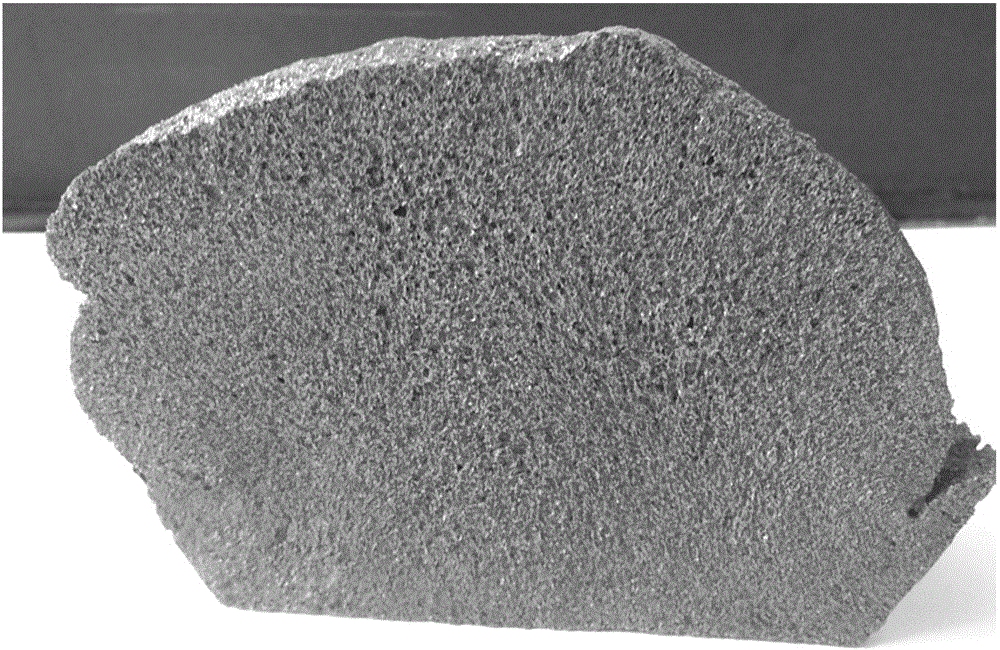

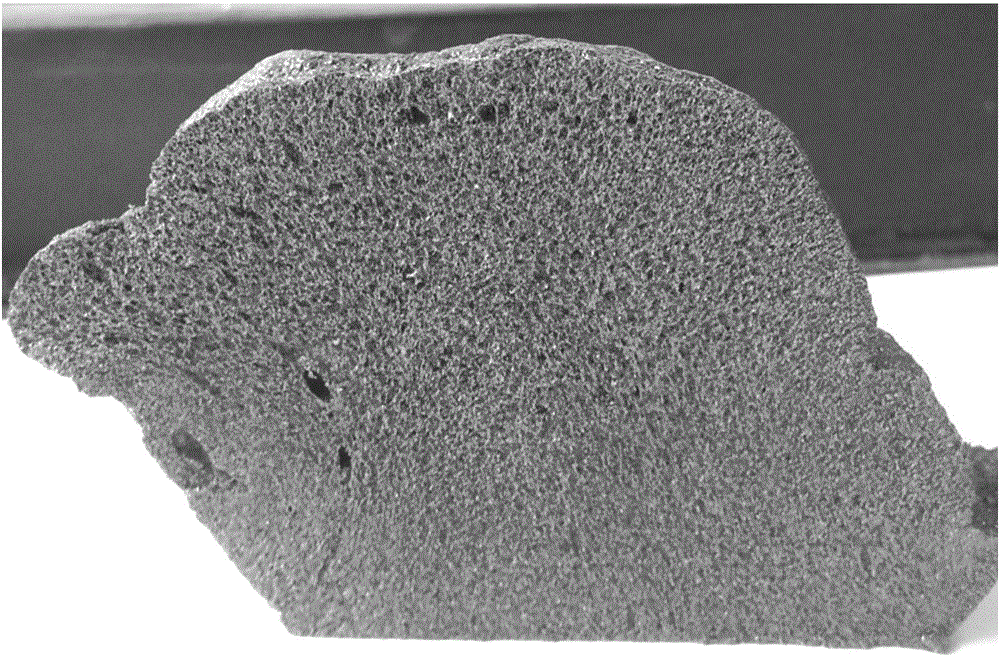

A resin grinding wheel

A technology of resin grinding wheel and phenolic resin is applied to resin grinding wheel. It can solve the problems of reduced strength of grinding wheel, small proportion of pores, and decreased grinding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Put 100g of alkali lignin (Shandong Quanlin Chemical Co., Ltd.) into 500g of NaOH solution with a mass concentration of 1%, stir until completely dissolved to obtain an alkali lignin solution, and then add 10g of formaldehyde to the above alkali lignin solution to obtain a reaction solution. The above reaction solution was heated to 95° C., and after 4 hours of reaction, a large amount of massive solids were precipitated in the reaction solution to obtain a reaction mixture, and the reaction was stopped at this time. The temperature of the above reaction mixture was lowered to 20° C., and after centrifugation, the solid obtained by centrifugation was dried in an oven at a drying temperature of 45° C. and a drying time of 6 hours to obtain 74.5 g of dried hydroxylated lignin. Finally, the above-mentioned dried hydroxylated lignin was pulverized to 200 mesh with a pulverizer to obtain powdery hydroxylated lignin A, ie coagent A.

[0055] Mix 1000g of 36# brown corundum, ...

Embodiment 2

[0058] Put 50g of alkali lignin (Shandong Quanlin Chemical Co., Ltd.) into 500g of NaOH solution with a mass concentration of 2%, stir until completely dissolved to obtain an alkali lignin solution, and then add 7.5g of furfural to the above alkali lignin solution to obtain reaction solution. The above reaction solution was heated to 85° C., and after 4 hours of reaction, a large amount of massive solids were precipitated in the reaction solution to obtain a reaction mixture, and the reaction was stopped at this time. The temperature of the above reaction mixture was lowered to 25° C., and after centrifugation, the solid obtained by centrifugation was dried in an oven at a drying temperature of 30° C. and a drying time of 10 hours to obtain 39.0 g of dried hydroxylated lignin. Finally, the above-mentioned dried hydroxylated lignin was pulverized to 150 mesh with a pulverizer to obtain powdery hydroxylated lignin B, ie coagent B.

[0059] Mix 720g of 36# brown corundum, 100g o...

Embodiment 3

[0062] Put 150g of calcium lignosulfonate (Shandong Gaotang Duoyuan Lignin Co., Ltd.) into 500g of NaOH solution with a mass concentration of 2%, stir until completely dissolved to obtain a calcium lignosulfonate solution, and then add the above-mentioned lignosulfonate Add 5 g of paraformaldehyde to the calcium solution to obtain a reaction solution. The above reaction solution was heated to 95° C., and after 4 hours of reaction, a large amount of massive solids were precipitated in the reaction solution to obtain a reaction mixture, and the reaction was stopped at this time. The temperature of the above reaction mixture was lowered to 30° C., and after centrifugation, the solid obtained by centrifugation was dried in an oven at a drying temperature of 60° C. and a drying time of 7 hours to obtain 108.4 g of dried hydroxylated lignin. Finally, the above-mentioned dried hydroxylated lignin was pulverized to 250 mesh with a pulverizer to obtain powdery hydroxylated lignin C, ie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com