A Class of Azodiphenylamine Disperse Dyes and Its Application

An azodiphenylamine-type disperse dye technology, which is applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of fiber specific surface area changes, poor light fastness, etc., and achieve the reduction of dyeing wastewater and various Excellent fastness and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

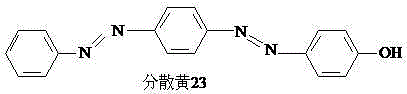

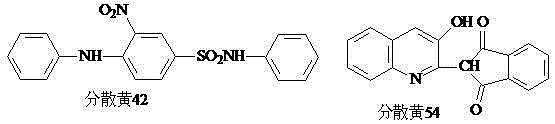

Problems solved by technology

Method used

Image

Examples

Embodiment 1

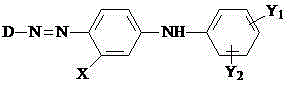

[0053] Referring to the examples in the invention patent GB1185174A, those skilled in the art can easily prepare dye monomers with structural formulas (a-1) and (a-2) by well-known methods.

[0054] (a-1)

[0055] (a-2)

[0056] Mix the two dye monomers (a-1) and (a-2) obtained in Example 1 with the diffusing agent. The mass ratio of the mixture is: dye monomer (dry product): dispersant MF: lignin sulfonate Sodium acid (85A) = 1:2:1, add appropriate amount of water and other surfactants, sand mill to a certain particle size, preferably less than 1 μm in particle diameter, and then spray dry to obtain commercial (a-1) formula Disperse dyes and (a-2) disperse dyes, wherein (a-1) formula disperse dyes are bright red on polyester fibers, and the maximum absorption wavelength λ in acetone MAX =510nm; (a-2) formula disperse dye is carnelian on polyester fiber, the maximum absorption wavelength λ in acetone MAX =528nm.

[0057] With reference to the examples in the invention ...

Embodiment 2

[0063] Referring to the examples in the invention patent GB1202984A, those skilled in the art can easily prepare dye monomers with structural formulas (b-1) and (b-2) by well-known methods. With reference to the commercialization method in Example 1 of the present invention, commercialized (b-1), (b-2) formula disperse dyes are obtained, wherein (b-1) formula disperse dyes are blue on polyester fibers, Maximum absorption wavelength λ in acetone MAX =612nm; (b-2) formula disperse dye is blue on polyester fiber, and the maximum absorption wavelength λ in acetone MAX =608nm.

[0064] (b-1)

[0065] (b-2)

[0066] Equally, with reference to the commercialization method in the embodiment in the invention patent GB1202984A and the embodiment 1 of the present invention, those skilled in the art can easily prepare the disperse dye shown in the general formula of Table 3 by the well-known method.

[0067] table 3

[0068]

Embodiment 3

[0070] Referring to the examples in the invention patent GB1166347A, those skilled in the art can easily prepare dye monomers with structural formulas (c-1), (c-2), (c-3), (c-4) by well-known methods . With reference to the commercialization method in Example 1 of the present invention, (c-1), (c-2), (c-3), (c-4) formula disperse dyes can be obtained, wherein (c-1) formula disperse The dye is reddish-orange on polyester fibers, and has a maximum absorption wavelength λ in acetone MAX =460nm; (c-2) formula disperse dye is red and orange on polyester fiber, and its maximum absorption wavelength in acetone is λ MAX =452nm; (c-3) formula disperse dye is yellowish orange on polyester fiber, and the maximum absorption wavelength λ in acetone MAX =434nm; (c-4) formula disperse dye is yellowish orange on polyester fiber, and the maximum absorption wavelength λ in acetone MAX =430nm.

[0071] (c-1)

[0072] (c-2)

[0073] (c-3)

[0074] (c-4)

[0075] Similarly, with refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com