Multifunctional fully hydraulic self-propelled highway anti-collision guardrail drilling machine

An anti-collision guardrail, full hydraulic technology, applied in the directions of roads, roads, drilling equipment, etc., can solve the problems of single machine, poor safety, low efficiency, etc., and achieve the effect of low cost of accessories, convenient maintenance and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

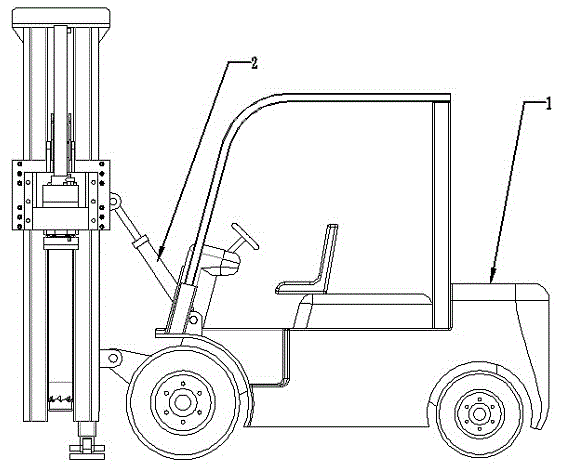

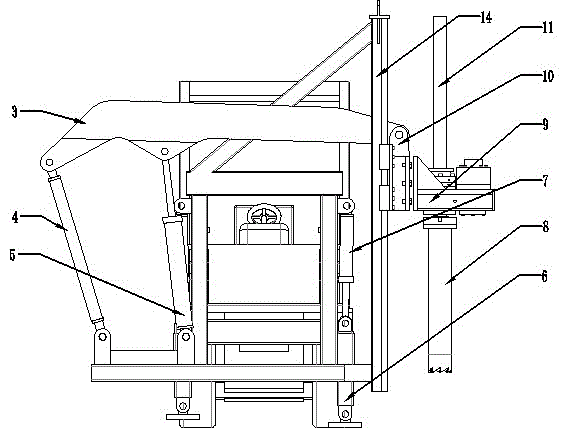

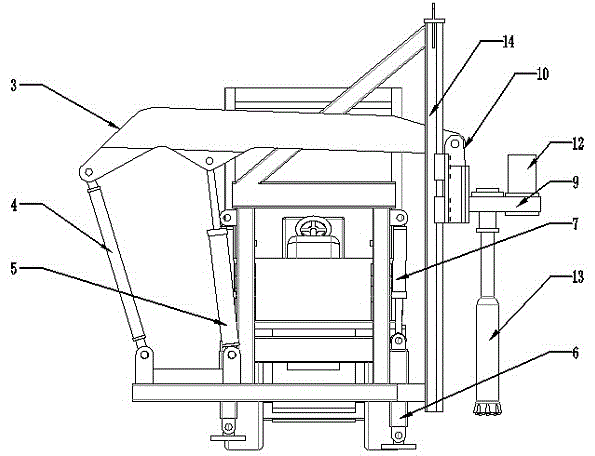

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The multi-functional fully hydraulic self-propelled highway anti-collision guardrail drilling and drilling machine includes a walking system 1, an inclined oil cylinder 2 is arranged in front of the walking system 1, and a support frame 14 is arranged on the inclined oil cylinder 2, wherein the support frame 14 is A lifting cylinder 5, a swing lever 4, a lifting arm 3 and a sliding frame 10 are provided, one end of the lifting arm 3 is hinged on the swinging lever 4, the other end is hinged on the sliding frame 10, and the middle part is hinged on the lifting cylinder 5 The lift cylinder 5 drives the lifting arm 3 to lift, and the swing lever 4 structurally shifts left and right to support, drives the slide frame 10 to vertically take off and land on the support guide rail, and replaces the core bit 8, the impactor 13, and the hydraulic pressure on the slide frame 10. Hammer 15, pile pulling frame 16, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com