Steam turbine thermalized steam flow single-reheat power and power co-production thermal system

A thermal system and steam turbine technology, which is applied in the direction of steam central heating system, heating system, steam engine installation, etc., to achieve the effect of perfect thermal cycle, comprehensive benefits of energy saving and emission reduction, and stable heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

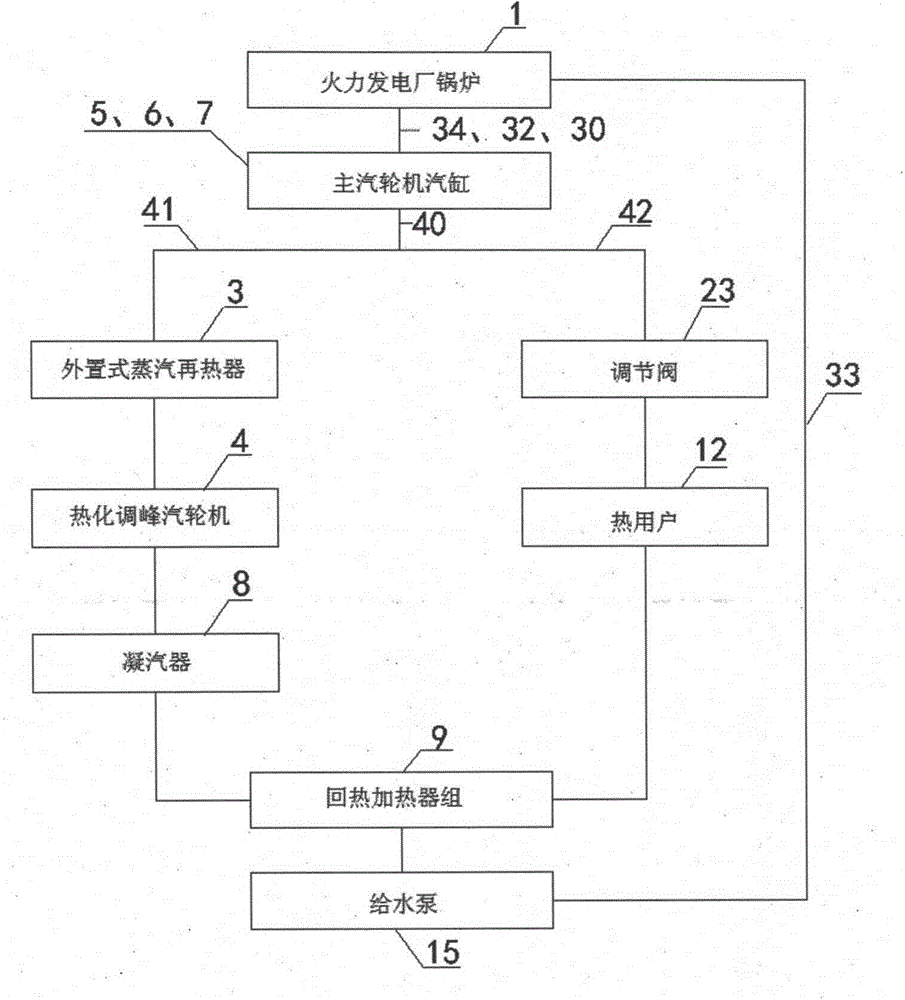

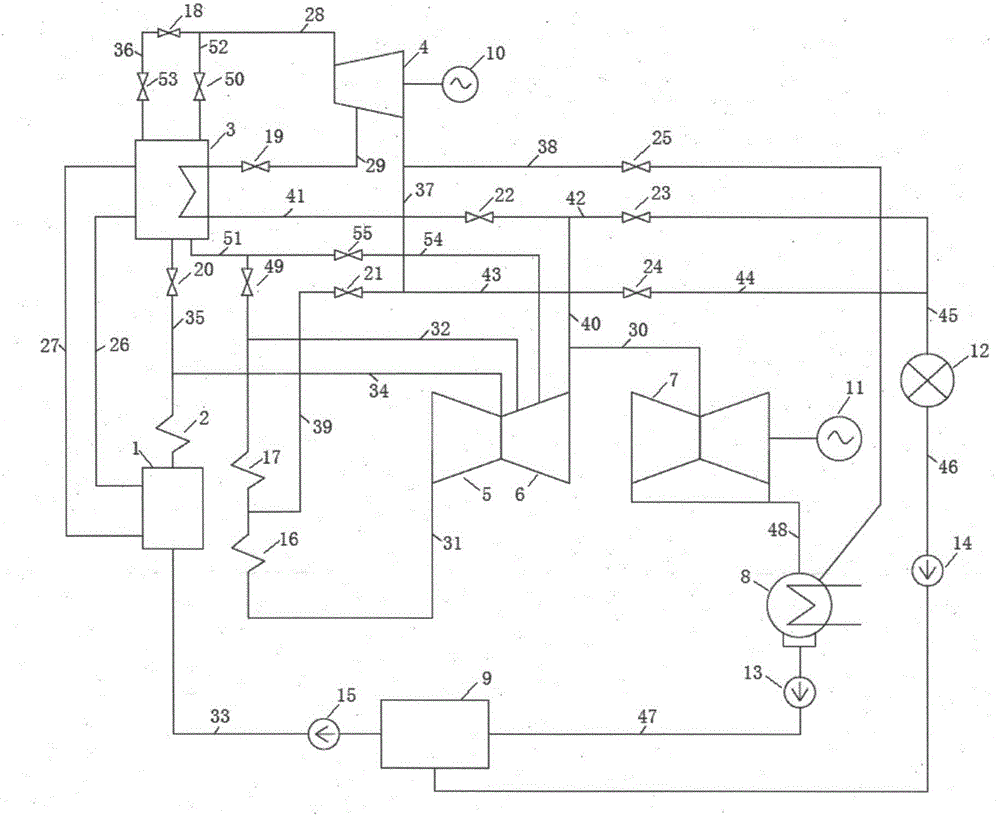

[0013] like figure 1 Shown is a schematic diagram of the principle of a steam turbine thermalization steam flow primary reheating and electricity cogeneration thermal system of the present invention, including a thermal power plant boiler 1, main steam turbines 5, 6, 7, external steam reheater 3, thermal conditioning Peak steam turbine 4, regulating valve 23, regenerative heater group 9, feed water pump 15, heat user 12, pipelines 30, 32, 33, 34, 40, 41, 42, etc.

[0014] The steam from the boiler 1 of the thermal power plant enters the main steam turbine cylinders 5, 6, and 7 through the pipelines 34, 32, and 30 to perform work. The external steam reheater 3 is heated, and the heated steam enters the thermal peak-shaving steam turbine 4 to do work, and the steam flow completes the function of electricity and electricity co-production; the other part of the steam enters the heat user through the pipeline 42 and the adjustment of the regulating valve 23 12 for heat supply, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com