Control system for stable dual-fuel load switching of solid heat carrier furnace

A solid heat carrier and control system technology, applied in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problem of changes in the calorific value of pyrolysis gas of pyrolysis products, switching control systems that cannot meet control requirements, and different types of auxiliary fuels OK, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

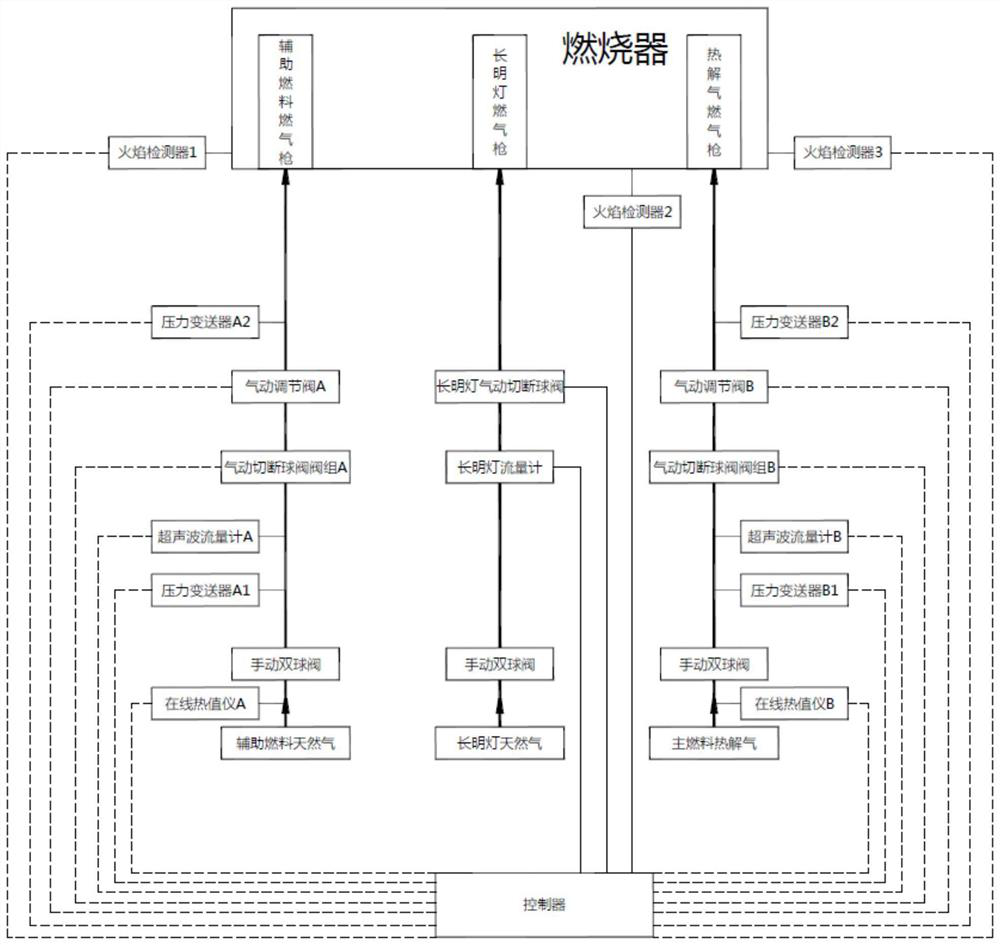

[0026] Such as figure 1 As shown, the control system for the steady switching of the dual-fuel load of the solid heat carrier furnace of the present invention includes a controller, an ever-burning lamp flowmeter connected to the controller, an ultrasonic flowmeter A, an ultrasonic flowmeter B, an ever-burning lamp pneumatic cut-off ball valve, a pneumatic Cut-off ball valve group A, pneumatic cut-off ball valve group B, pneumatic control valve A, pneumatic control valve B, pressure transmitter A, pressure transmitter B, online calorific value meter A, online calorific value meter B.

[0027] The burner is designed with an independent permanent lamp gas gun, auxiliary fuel gas gun and pyrolysis gas gun, which are connected to independent gas pipelines. The pilot lamp gas gun is connected to the pilot lamp flowmeter and the pilot lamp pneumatic cut-off ball valve in sequence through the pilot lamp pipeline; the auxiliary fuel gas gun of the burner is connected to the online cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com