A gas stove that improves energy efficiency

A gas stove and energy efficiency technology, which is applied in the field of gas stoves, can solve the problems that the energy efficiency of gas stoves cannot be greatly improved, and achieve the effects of stable heat load, sufficient combustion, and reduced stove surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

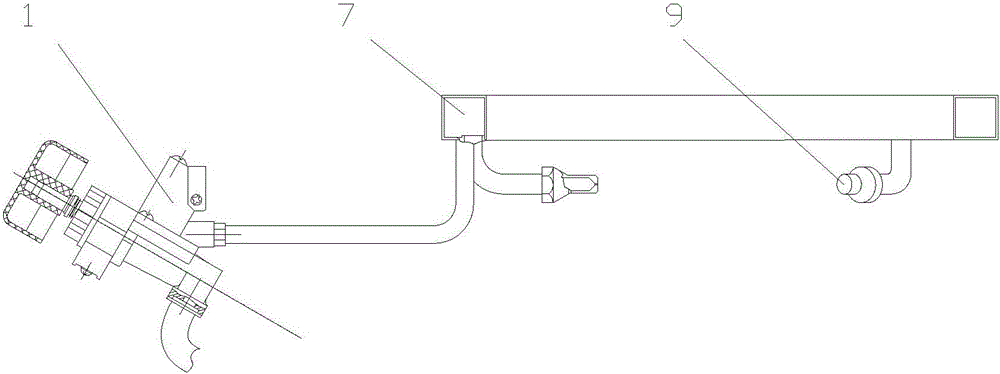

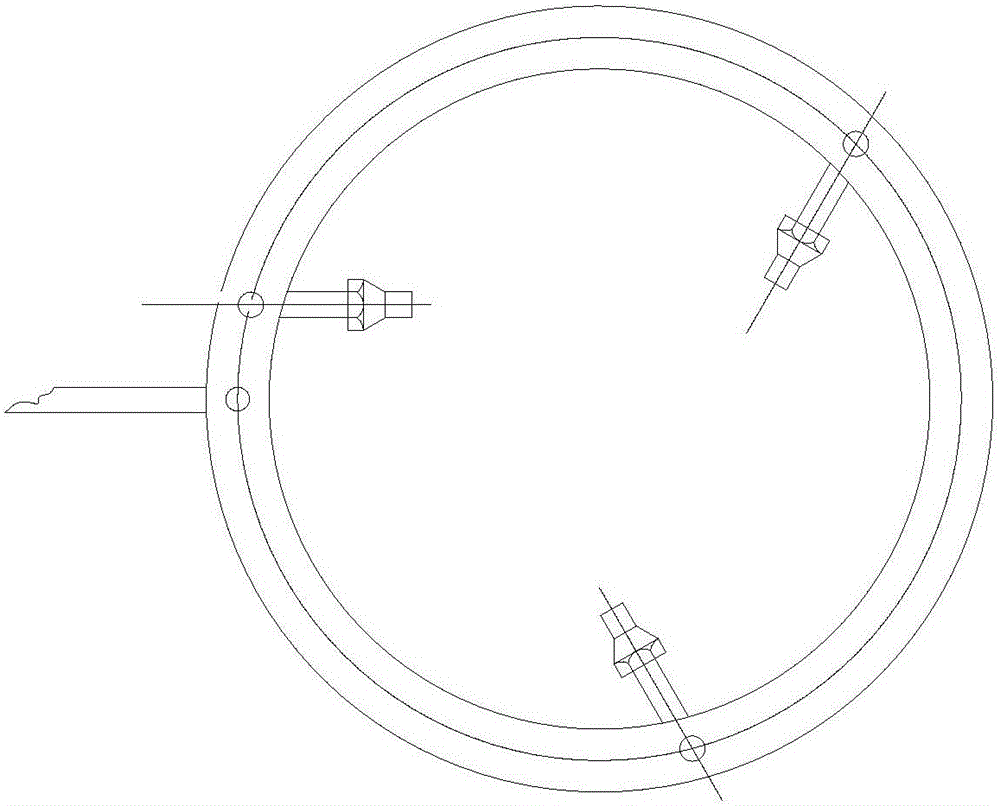

[0028] The present invention chooses to recover the waste heat preheating design of the flue gas at the bottom of the pot, and the specific implementation is as follows figure 1 , 2 : The gas flows from the intake main pipe 15 through the gas stove valve body assembly 1 and the cock valve outlet pipe 4, and then enters the gas preheating distribution ring pipe 7 made of heat-resistant stainless steel square pipe, and then enters the nozzle 9 through the nozzle inlet pipe 8, and the nozzle The gas is ejected to the respective injection pipes. The wall thickness of the gas preheating distribution ring pipe is ≥0.4-0.8mm, and the inner diameter of the ring is ≥220mm. The pot bracket 6 is installed on the gas preheating distribution ring pipe. The distance between the top of the ring pipe and the bottom of the pot should be ≥10mm. The cross-sectional area of the flow is ≥ 3 times the diameter of the gas valve.

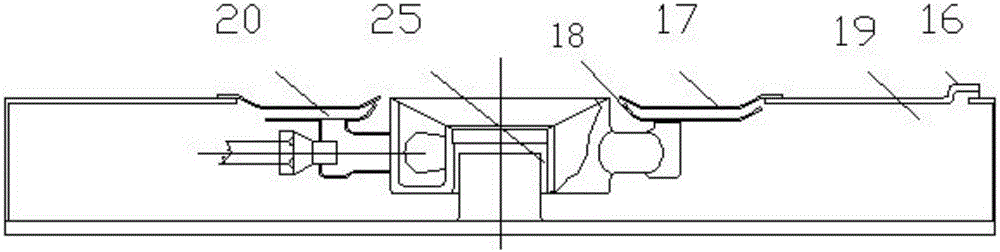

[0029] Such as image 3 , 4 As shown: the air preheating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com