Combustion radiator and combustion method of multi-ejecting-tangent-circle premixing porous medium gas stove

A porous medium and ejector technology, which is applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of reduced combustion efficiency and thermal efficiency, incomplete combustion, and increased cost, so as to improve thermal efficiency and combustion efficiency, The effect of reducing pollutant emissions and enhancing combustion intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

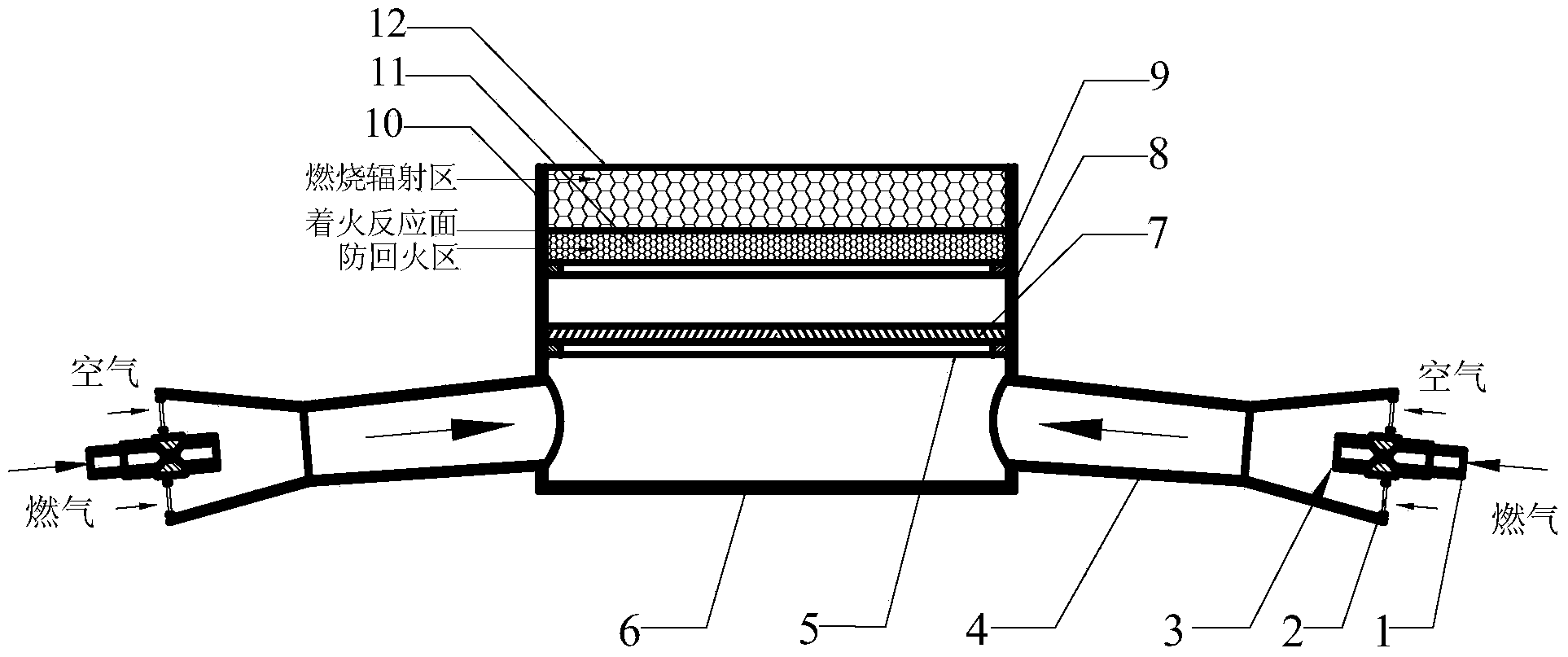

[0026] Attached below figure 1 The present invention will be described in detail.

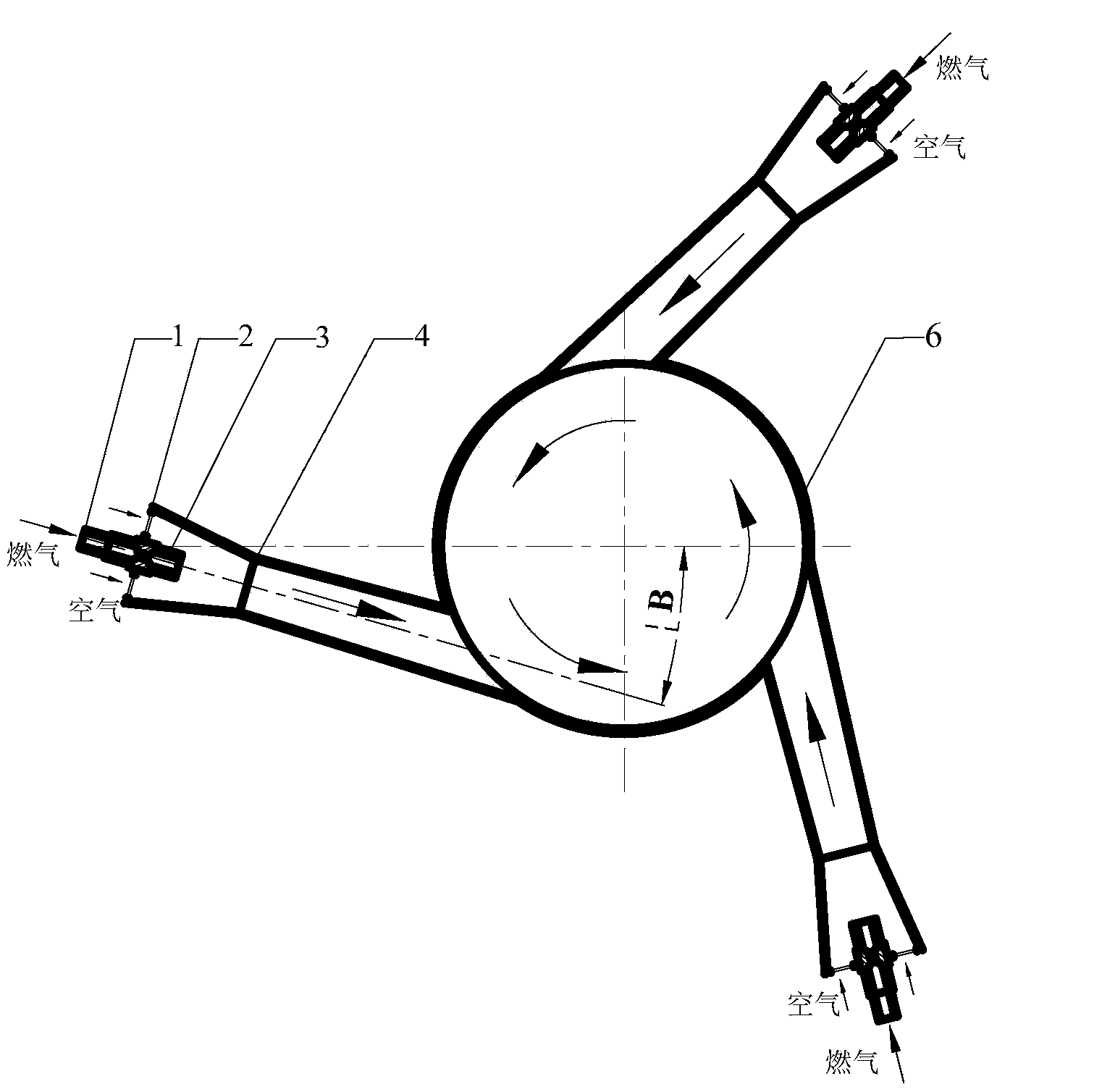

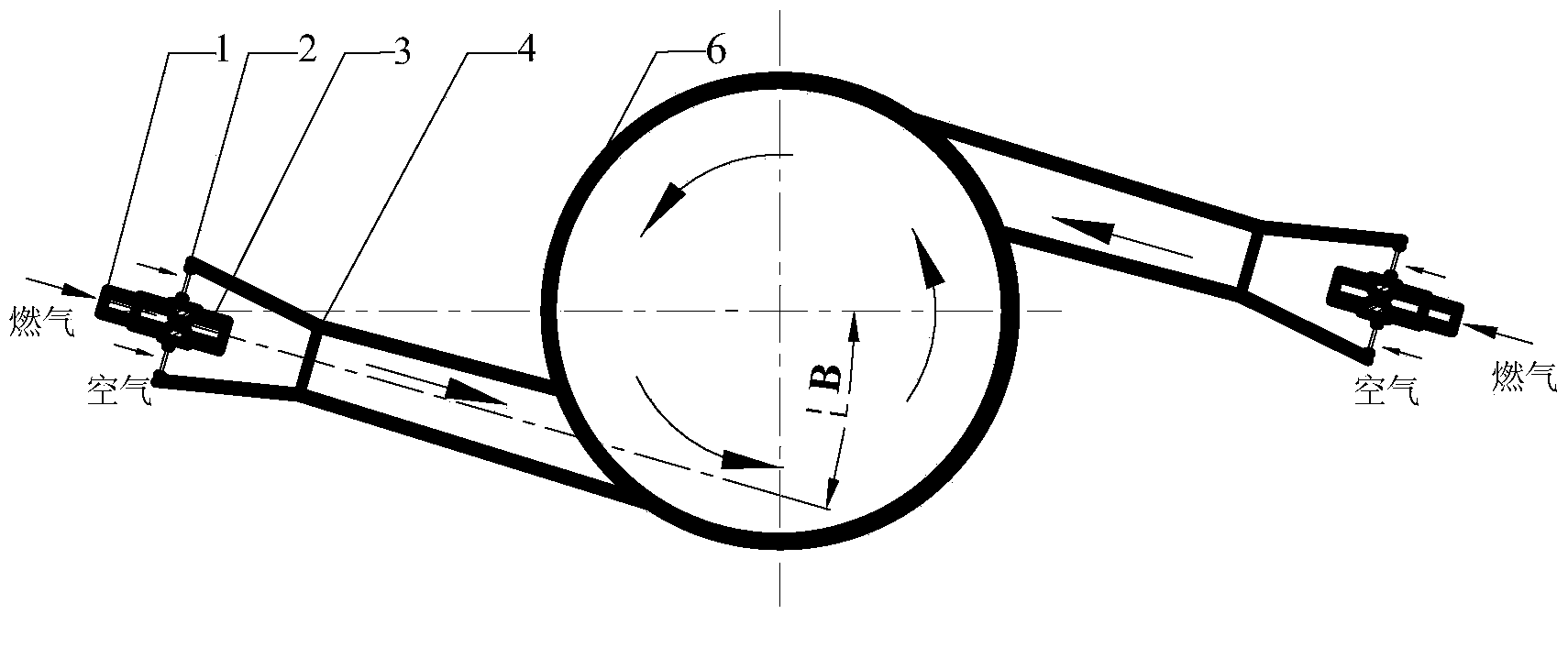

[0027] Such as figure 1 As shown, the device of the present invention includes a gas injector 3 and a Venturi injector 4. The circumferential direction of the gas injector 3 is an air inlet 2, the beginning end is a gas inlet 1, and a gas tangential circle is provided at the end of the Venturi injector 4. The rotary premixer 6 is provided with a support frame 5 at the upper end of the gas rotary mixer 6, and the support frame 5 is fixed on the inner wall of the upper end of the gas swirl mixer 6, and the support frame 5 is provided with an air flow uniform distributor 7, and the air flow uniform distributor 7 is provided with a gas secondary mixing chamber 8, and the upper inner wall of the gas secondary mixing chamber 8 is provided with a support frame 9, and a porous medium combustion radiator 10 is provided above the support frame 9. The specific dimensions of Venturi ejector, gas tangenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com